Introduction

Matériaux

Outils

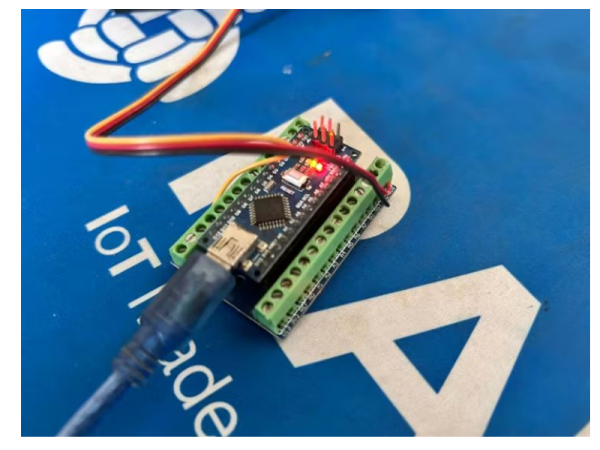

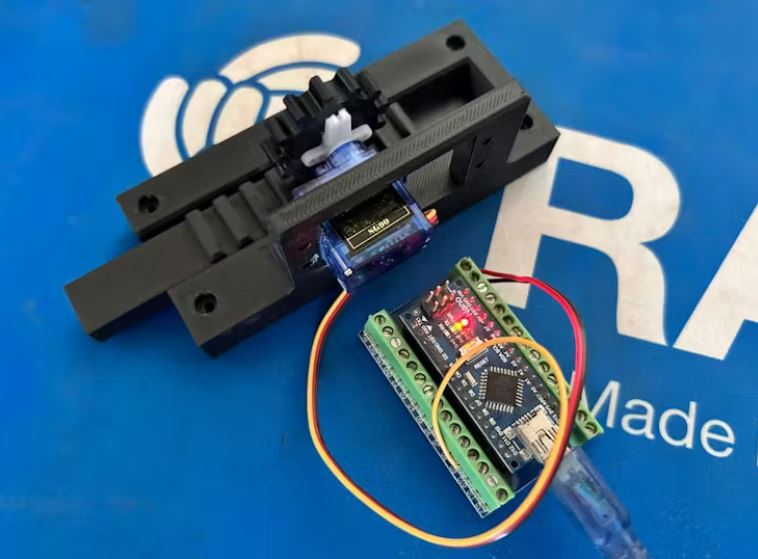

Étape 1 - Components Required

- Arduino Nano (official or compatible board)

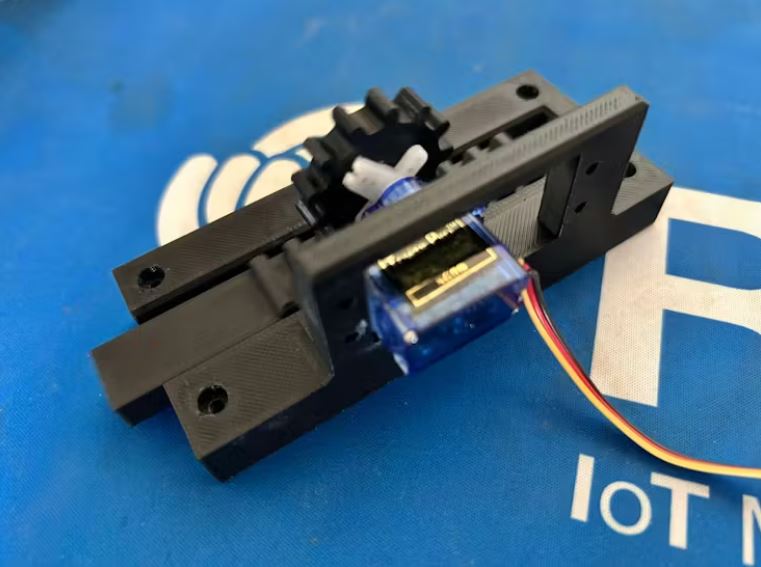

- Servo Motor (e.g., SG90 micro servo)

- Jumper wires

- USB cable (Mini-B) for programming

Étape 2 - Get PCBs for Your Projects Manufactured

You must check out PCBWAY for ordering PCBs online for cheap!

You get 10 good-quality PCBs manufactured and shipped to your doorstep for cheap. You will also get a discount on shipping on your first order. Upload your Gerber files onto PCBWAY to get them manufactured with good quality and quick turnaround time. PCBWay now could provide a complete product solution, from design to enclosure production. Check out their online Gerber viewer function. With reward points, you can get free stuff from their gift shop. Also, check out this useful blog on PCBWay Plugin for KiCad from here. Using this plugin, you can directly order PCBs in just one click after completing your design in KiCad.

Étape 3 - Understanding the Servo Motor

Wires:

- Red → VCC (typically 5V)

- Brown/Black → GND

- Orange/Yellow → Signal (PWM input)

Working Principle: The servo motor rotates to a specific angle (0°–180°) based on the PWM signal sent from the Arduino

Circuit Connections

- Connect servo VCC (red) to 5V pin of Arduino Nano

- Connect servo GND (black/brown) to GND pin of Arduino Nano.

- Connect servo signal (orange/yellow) to digital pin D9 of Arduino Nano (you can choose other PWM-capable pins).

- If using a high-torque servo, power it with an external 5V supply and connect grounds together to avoid damaging the Nano

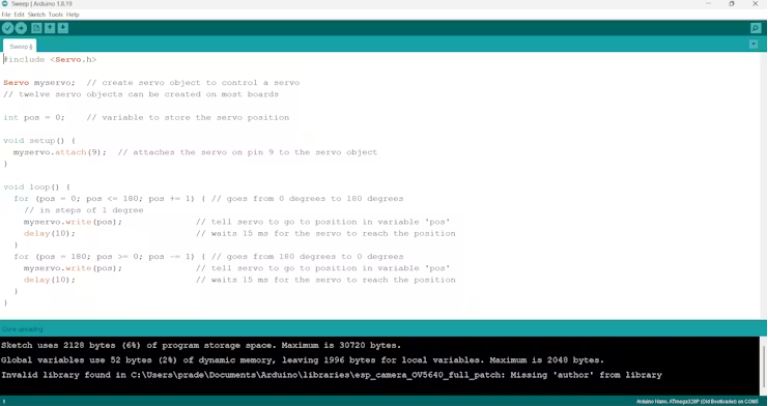

Étape 4 - Installing the Servo Library

The Arduino IDE comes with a built-in Servo.h library.

- Open Arduino IDE → Go to Sketch > Include Library > Servo.

- This library simplifies sending PWM signals to the servo.

#include <Servo.h>

Servo myservo; // create servo object to control a servo

// twelve servo objects can be created on most boards

int pos = 0; // variable to store the servo position

void setup() {

myservo.attach(9); // attaches the servo on pin 9 to the servo object

}

void loop() {

for (pos = 0; pos <= 180; pos += 1) { // goes from 0 degrees to 180 degrees

// in steps of 1 degree

myservo.write(pos); // tell servo to go to position in variable 'pos'

delay(10); // waits 15 ms for the servo to reach the position

}

for (pos = 180; pos >= 0; pos -= 1) { // goes from 180 degrees to 0 degrees

myservo.write(pos); // tell servo to go to position in variable 'pos'

delay(10); // waits 15 ms for the servo to reach the position

}

}

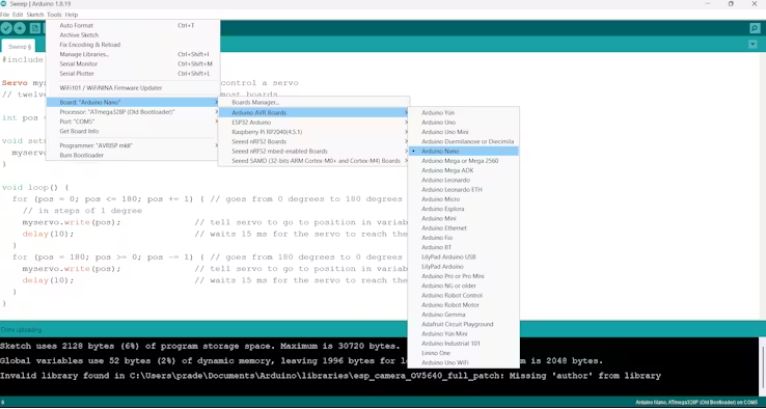

Étape 5 - Uploading the Code

- Connect Arduino Nano to your PC via USB.

- Select Tools > Board > Arduino Nano.

- Choose the correct Port.

- Click Upload.

- The servo should start sweeping back and forth.

Étape 6 - Testing and Troubleshooting

- If the servo jitters, provide external power.

- Ensure common ground between Arduino and external supply.

- If the servo doesn’t move, check wiring and pin assignment.

- Use

myServo.write(angle)to set specific angles (e.g.,myServo.write(90)for center position).

Expanding the Project

- Control servo with a potentiometer for manual angle adjustment.

- Use ultrasonic sensors to make the servo respond to distance.

- Integrate with Bluetooth/Wi-Fi modules for remote control.

Étape 7 - Conclusion

Published

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português