Sommaire

- 1 Introduction

- 2 Video d'introduction

- 3 Étape 1 - Mounting Pulley Wheel on Motor Shaft

- 4 Étape 2 - Glue Popsicle Stick for Pulley Holder

- 5 Étape 3 - Plastic Pulley Wheel Holder Assembly

- 6 Étape 4 - Drill a Hole on Slingshot

- 7 Étape 5 - Mount Plastic Pulley on Slingshot

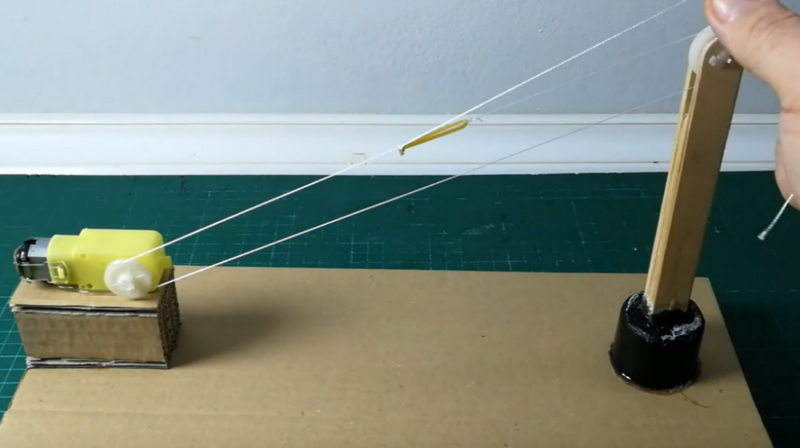

- 8 Étape 6 - Motor Base

- 9 Étape 7 - Motor Assembly

- 10 Étape 8 - Pulley Holder Mount

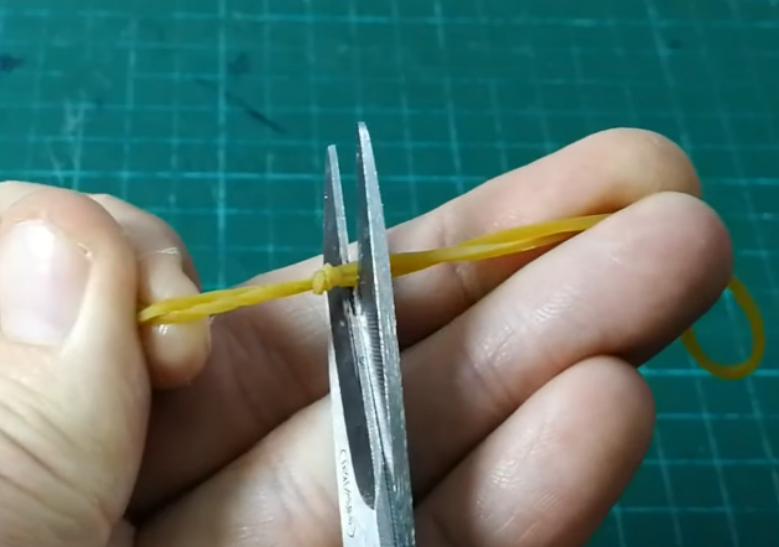

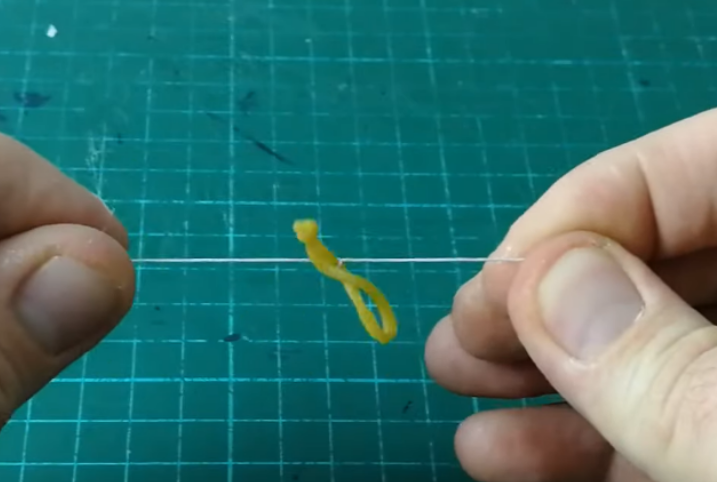

- 11 Étape 9 - Thread Tension Control

- 12 Étape 10 - Attach Tension Control Onto Yarn

- 13 Étape 11 - Attach the Cable

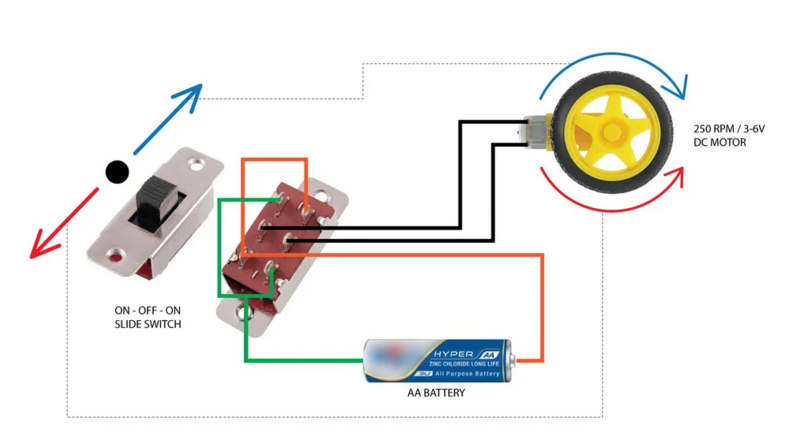

- 14 Étape 12 - Soldering System

- 15 Étape 13 - Motor Soldering

- 16 Étape 14 - Battery Attachment

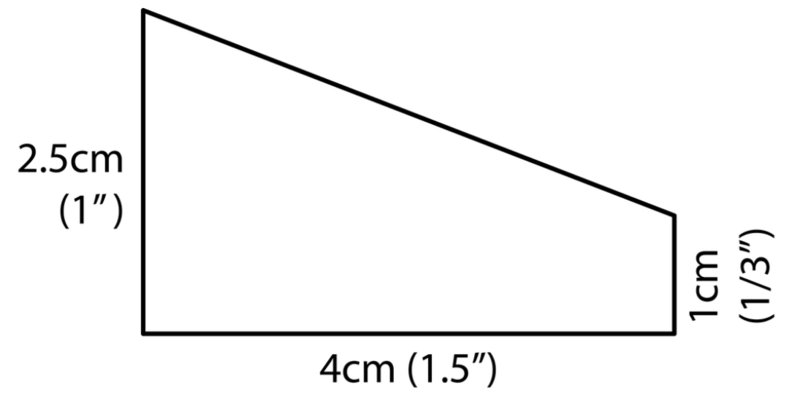

- 17 Étape 15 - Cable Car Cabin Assembly

- 18 Étape 16 - Cut Cabin Hanger 30º Angled

- 19 Étape 17 - Glue Hanger

- 20 Étape 18 - Attach the cabinet to the rope

- 21 Étape 19 - Play it

- 22 Commentaires

Introduction

Youtube

Matériaux

• 1pcs 25*35cm 5mm Cardboard for project Ground

• 8pcs popsicle stick (15cm)

• 2pcs Plastic Pulley Wheel (Recycled from old CD/DVD burner)

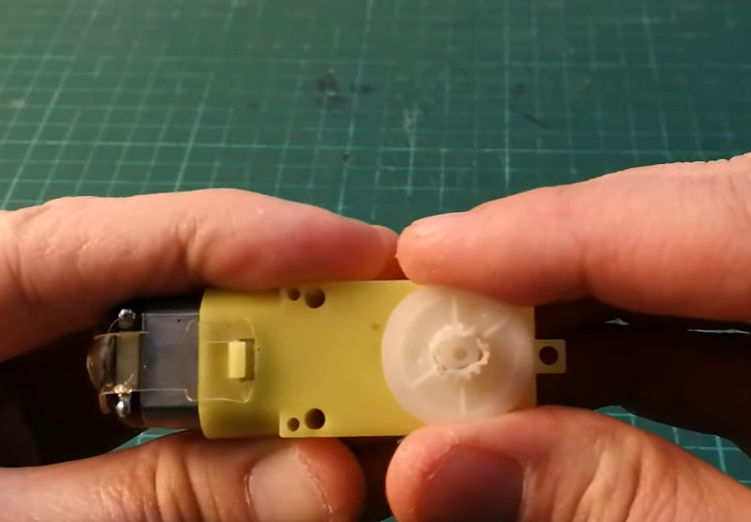

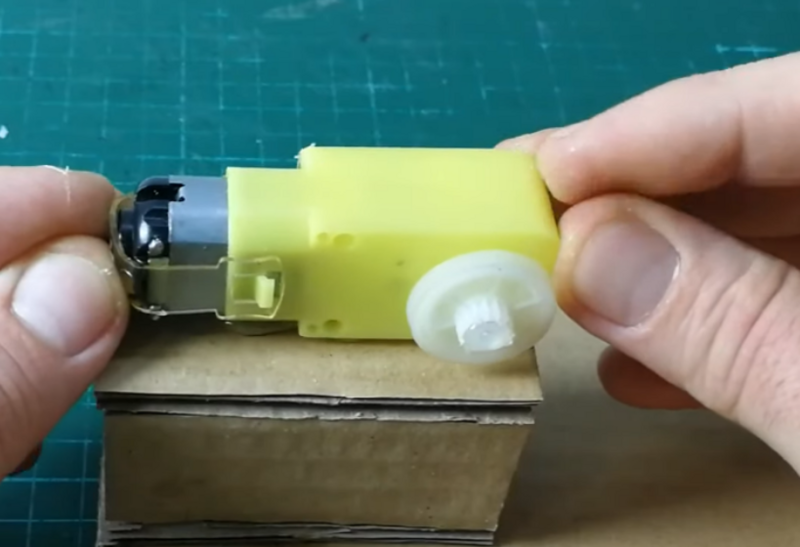

• 1pcs DC BO Motor (6V)

• 7x4x3cm cardboard Block (Stacked 6pcs 4*7cm cardboard)

• Plastic Bottle Cap

• 4pcs Match

• 1pcs Battery Holder

• 1pcs DPDT On-Off-On Slide Switch

• Passengers (Optional)

• Nylon yarn

• 1pcs thin nail

Outils

• soldering iron

• Cutter

• Glue

Étape 1 - Mounting Pulley Wheel on Motor Shaft

You can check all steps on video briefly or follow below steps.

• Mount plastic pulley wheel onto DC motor shaft and glue on it.

Étape 2 - Glue Popsicle Stick for Pulley Holder

Glue the popsicle sticks on top of each other.

1 set of 4 sticks will be glued on top of each other.

2 sets of 2 sticks will be glued on top of each other.

Étape 3 - Plastic Pulley Wheel Holder Assembly

Glue the popsicle sticks together in the form of a slingshot, keeping the group of 4 in the middle.

Étape 5 - Mount Plastic Pulley on Slingshot

Mount plastic pulley wheel with a nail between slingshot arms.

Étape 8 - Pulley Holder Mount

Glue pulley holder slingshot onto plastic bottle cap to increase height.

Glue pulley holder slingshot onto right side of base.

Étape 11 - Attach the Cable

Tie the yarn between the pulleys by adjusting the tension with the rubber band.

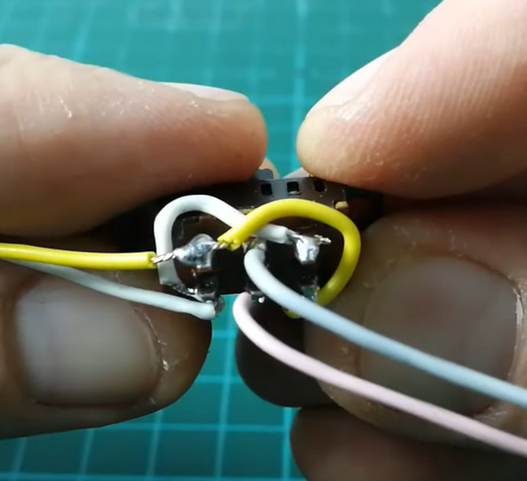

Étape 12 - Soldering System

Solder the wires onto the 6 pin slide switch for forward and reverse movement.

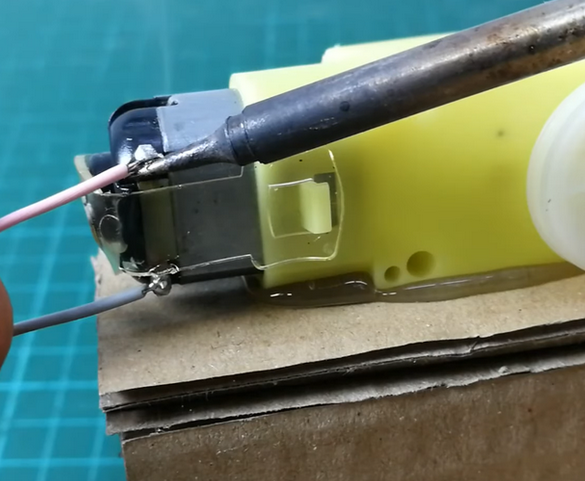

Étape 13 - Motor Soldering

Solder the cables coming from the middle pins of the slide switch to the motor pins.

Étape 14 - Battery Attachment

Solder the cables from the other ends to the pins on the battery holder.

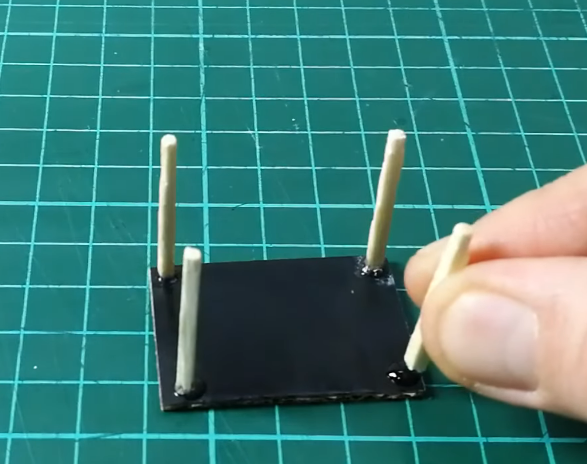

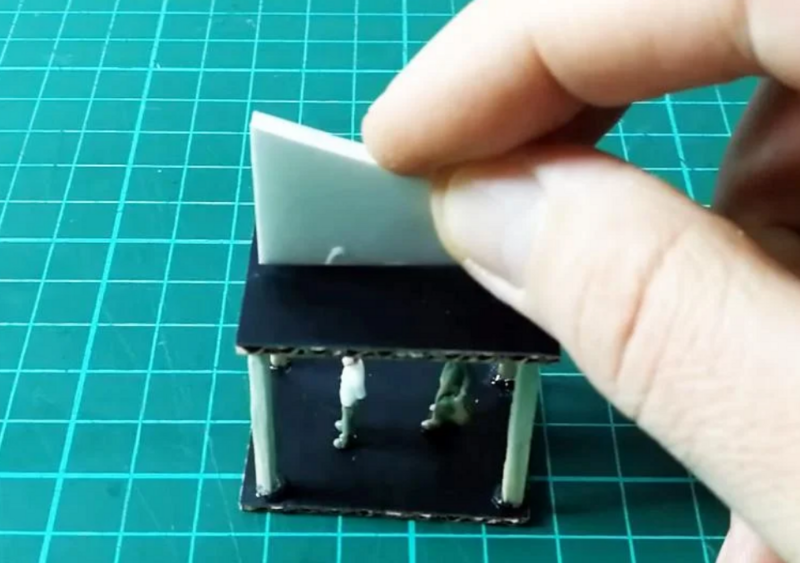

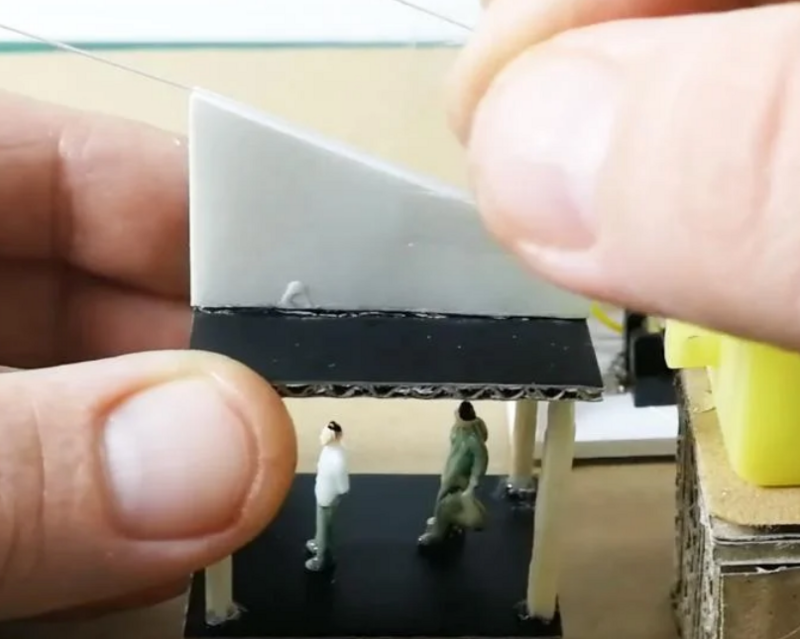

Étape 15 - Cable Car Cabin Assembly

Cut away 4pcs Match heads.

Prepare 2pcs 4x3cm 3mm cardboard and glue Matches on the corners.

Don't forget the Passengers

Étape 19 - Play it

Start the cable car by moving the switch back and forth, have fun 👏👏👏👏

Published

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português