Sommaire

- 1 Introduction

- 2 Video d'introduction

- 3 Étape 1 - Starting with a cardboard prototype

- 4 Étape 2 - Making about 25 prototypes (or close to) to get it running

- 5 Étape 3 - If you only want to reproduce, start here!

- 6 Étape 4 - Setup of the laser cutting machine

- 7 Étape 5 - Tank module in the shape of a pixelated heart

- 8 Étape 6 - Rotating delivery system module

- 9 Étape 7 - "Turn" module

- 10 Étape 8 - Small straight section

- 11 Étape 9 - Long straight section

- 12 Étape 10 - ending module

- 13 Étape 11 - Modules assembly

- 14 Étape 12 - Adding some color (painting)

- 15 Étape 13 - Level assembly

- 16 Étape 14 - Once placed on the wall...

- 17 Étape 15 - ... and filled with candies!

- 18 Notes et références

- 19 Commentaires

Introduction

You like peanuts covered with chocolate and retro video games?

You've got a desperatly empty wall and would like to pay tribute to the most famous plumber ?

Then here is a tutorial which will help you building a candy dispenser (for candies starting with M and ending with M) inspired by Mario's first appearance in a video game when he faced a certain Donkey Kong.

It's a completely customizable project, you'll be able to build the level of your dreams for your candies. Indeed the course you will create is made of modules that you can assemble as you want in almost any order as in a building game.

This project is made using only laser cutting (well, there's a few bolts and some glue and paint involved in the process...)

I hope you'll get the feeling of my project and create new modules, or imagine other themes for the decorations. It's up to you !

Matériaux

- Poplar plywood in 3mm thickness

- Transparent PMMA in 3mm thickness

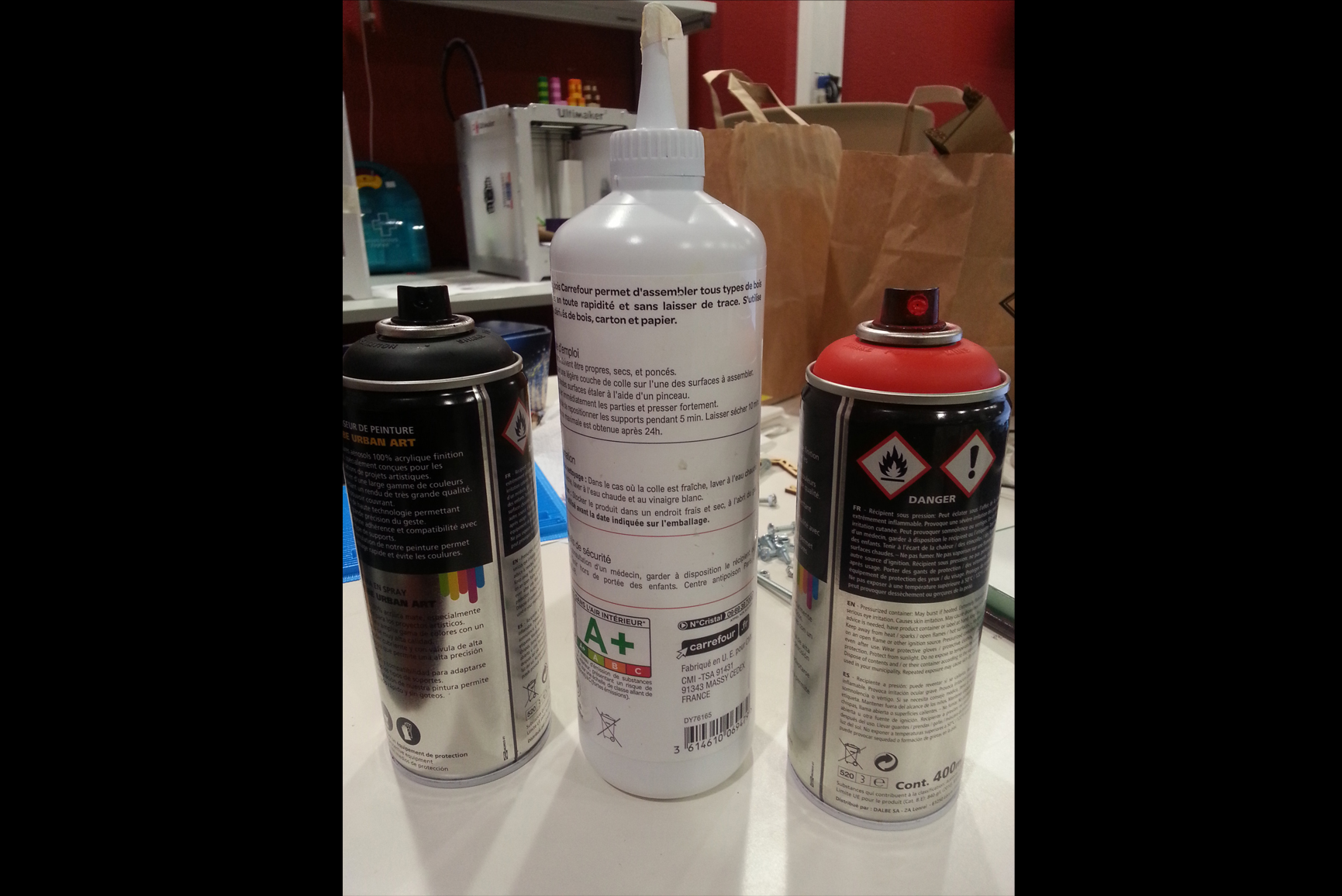

- Wood glue

- 4mm screws (50mm long) and nuts

- Red and black paint (green and white for the flag)

- M&M's

Outils

- Vector drawing software, here Illustrator (or Inkscape)

- Laser cutting machine (I used the Trotec Speedy 300 from my favorite fablab)

- Brush

- Sandpaper

- Candle (or wax)

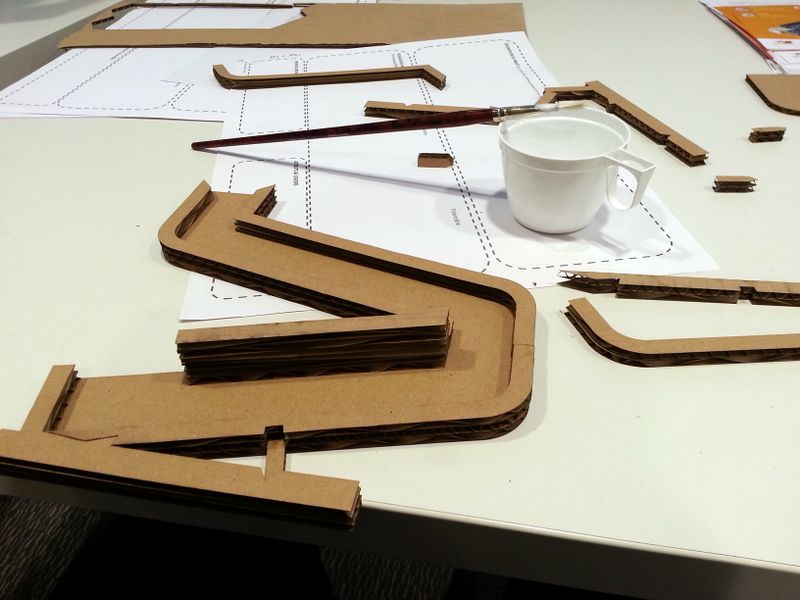

Étape 1 - Starting with a cardboard prototype

This step is only required if you start from scratch as I did (for example if you want to create new modules or a new theme)

After a few sketchs a a first file made using my favorite verctor graphic software I started by creating a cardboard prototype

This way you'll be able to quickly see what can and can not work and not waste wood unnecessarily. A file is very rarely perfect on the first run (or even the second!)

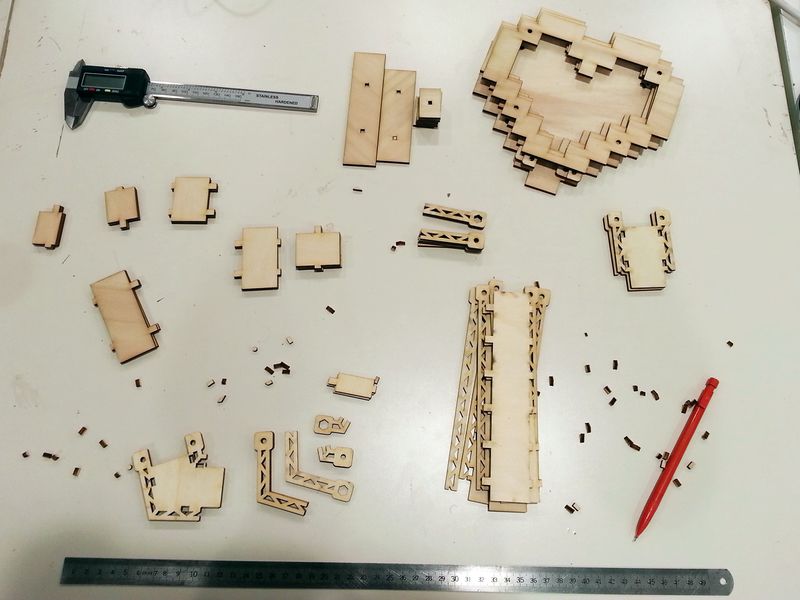

Étape 2 - Making about 25 prototypes (or close to) to get it running

Well, I may be exaggerating a little bit. After the first cardboard prototype I thought it would be nice to make the course completely modular (sometimes we have ideas like that... which we almost regret!).

Easy idea ... harder to get it done. Iterate. Test after test I ended up with something satisfactory.

The course making me think of Mario vs Donkey Kong I decided to make a retro gaming theme inspired by the beautiful era of 8bits...

What's nice is that you can keep the modules plugging system and only change the theme, to adapt it as you wish.

Étape 3 - If you only want to reproduce, start here!

As previously explained (admit that you jumped directly to this one), the principle of this distributor is that it is flexible! Simply put, if you want to make a journey 2 meters high it's possible. Just cut out the modules you need and assemble them in whatever order you want. For the moment I realized 6 modules:

- A candy container in pixelated heart (to take back lives)

- A rotating distribution system

- A turn (can be mounted as right or left turn)

- A small straight section

- A longer straight section

- And a terminating cup (with a nice end of level flag!)

In the future I'm counting on you to help me to make other nice modules (motorized distribution system, continuous distribution for kibble for example cat, waterfall, jump... looping... good ok I'm going too far.)

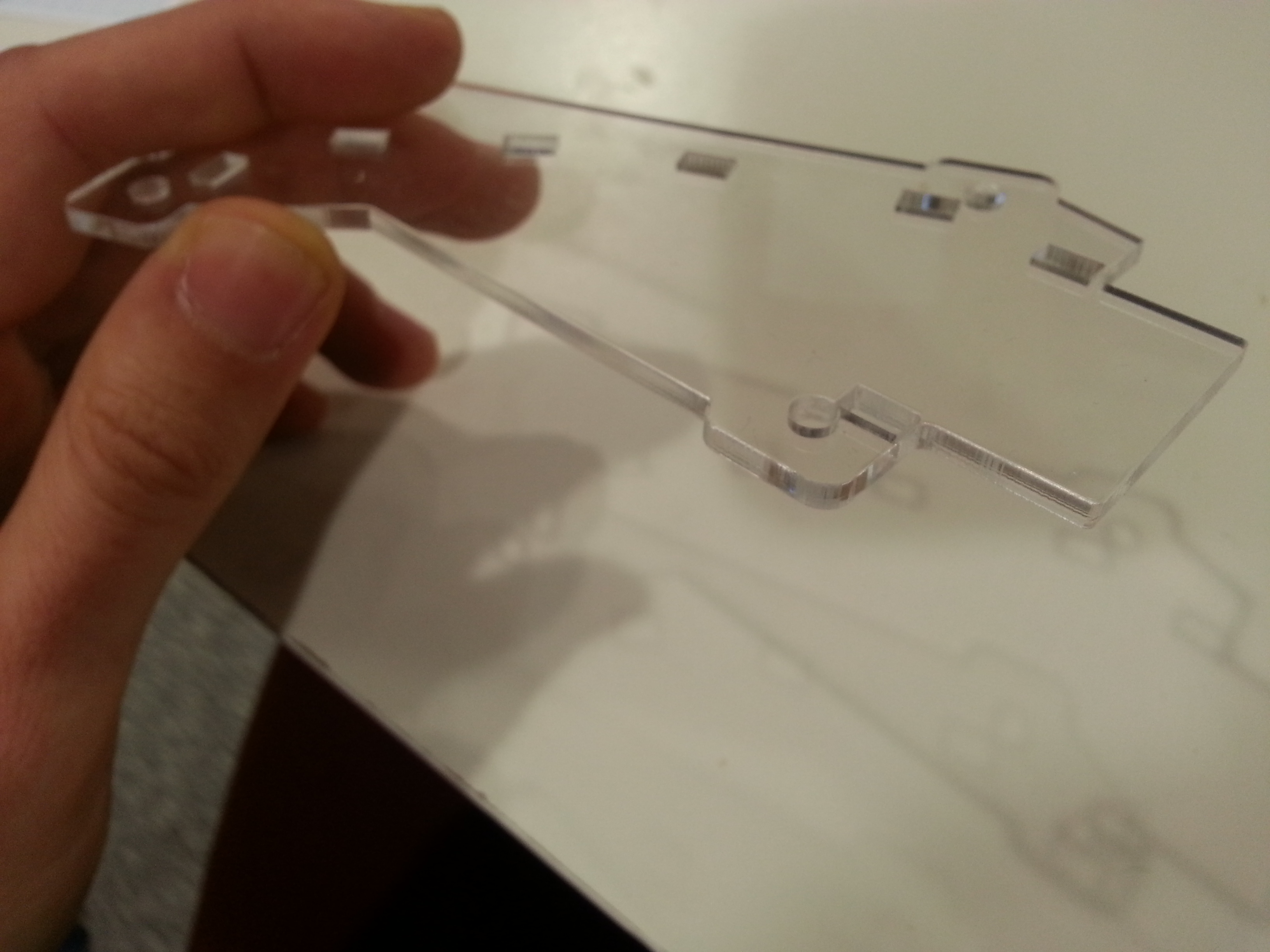

For these 6 modules you will find a corresponding file that will allow you to do it independently. For each module you need plywood and pmma with the exception of the rotary system which is all plywood.

I advise you to think ahead of the course you want to achieve and group several modules on a single cutting board depending on the size of your boards and laser cutting. By default each module can be cut on a board of 610 x 305 mm.

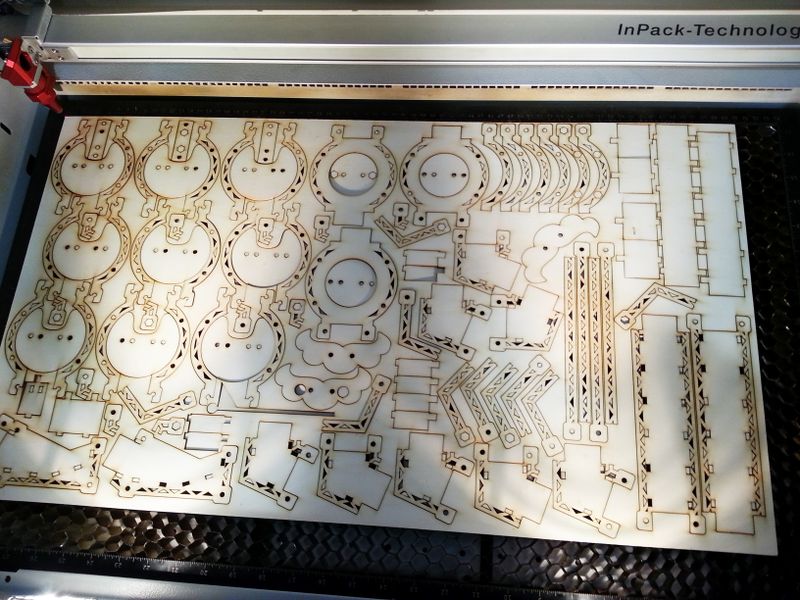

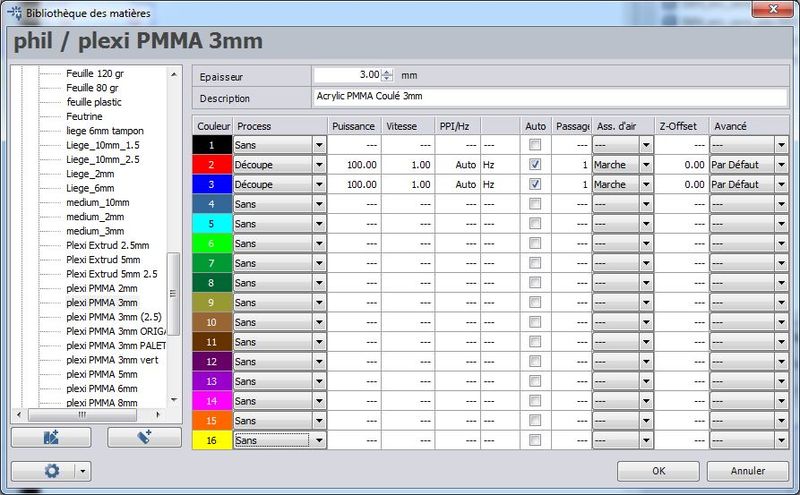

Étape 4 - Setup of the laser cutting machine

The material parameters for Trotec Speedy 300 laser cutting are as follows:

- Power: '80' Speed: '1.5' for 3mm poplar plywood

- Power: '100' Speed: '1' for 3 mm transparent PMMA

These settings are to be applied to the colors red, blue and green to allow the cutting of the interior parts before the exteriors... Written like that it may seem a little complicated, but if you look at the files you will understand better what I want to talk about.

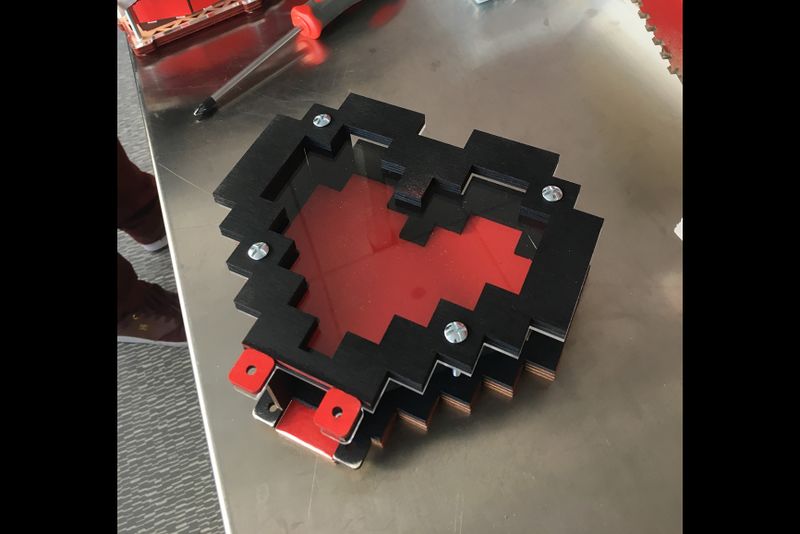

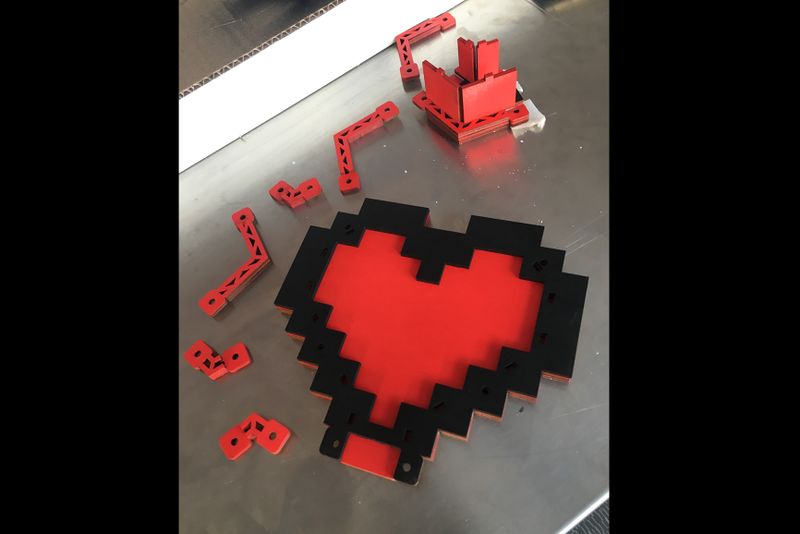

Étape 5 - Tank module in the shape of a pixelated heart

Laser cutting time for this module:

- for 3mm poplar plywood pieces: 3 minutes 45 seconds

- for 3mm transparent PMMA pieces: 38 seconds

SVG files : for plywood, for PMMA

PDF manual with help to build this module

AI file with all informations and content on different layers

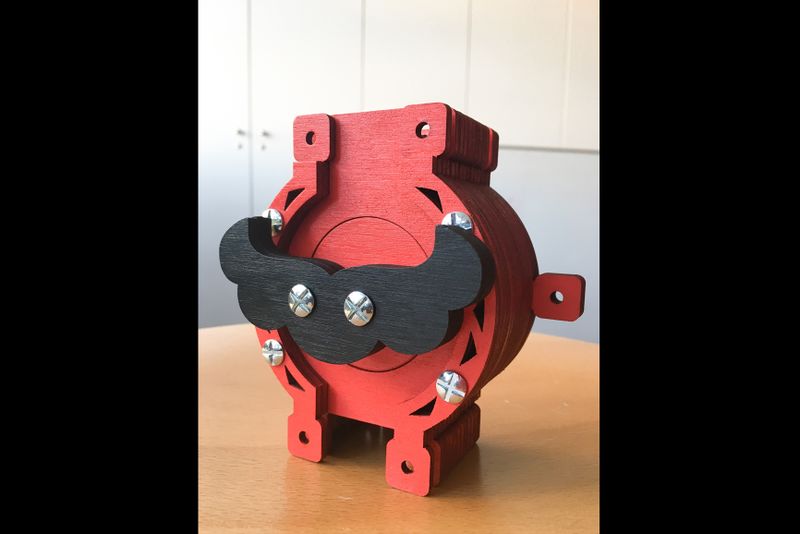

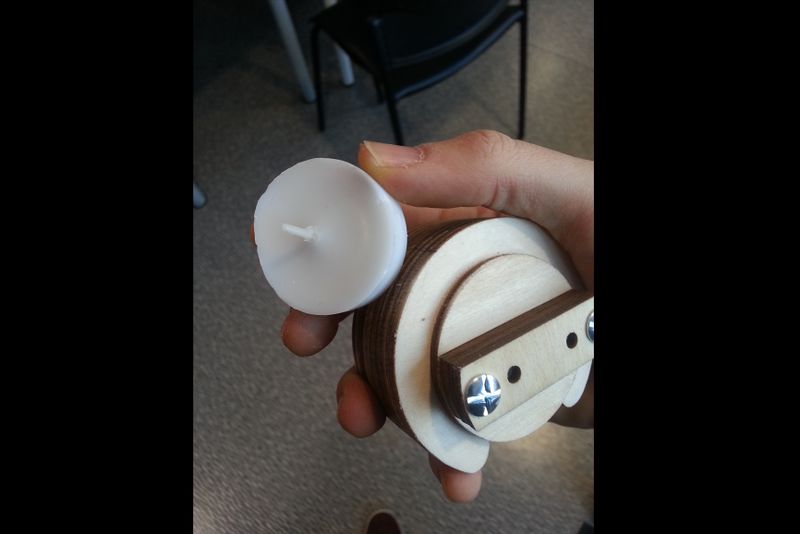

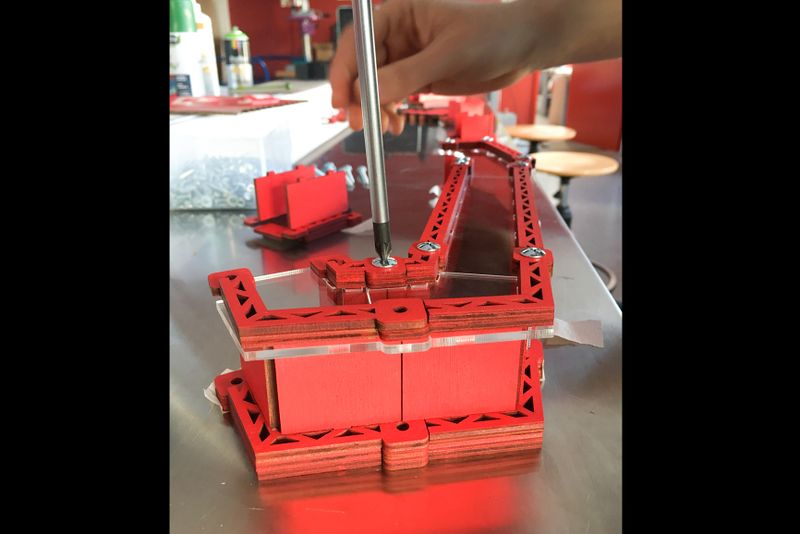

Étape 6 - Rotating delivery system module

Laser cutting time for this module:

- for 3mm poplar plywood pieces: 9 minutes 36 seconds

- no PMMA parts

PDF manual with help to build this module

AI file with all informations and content on different layers

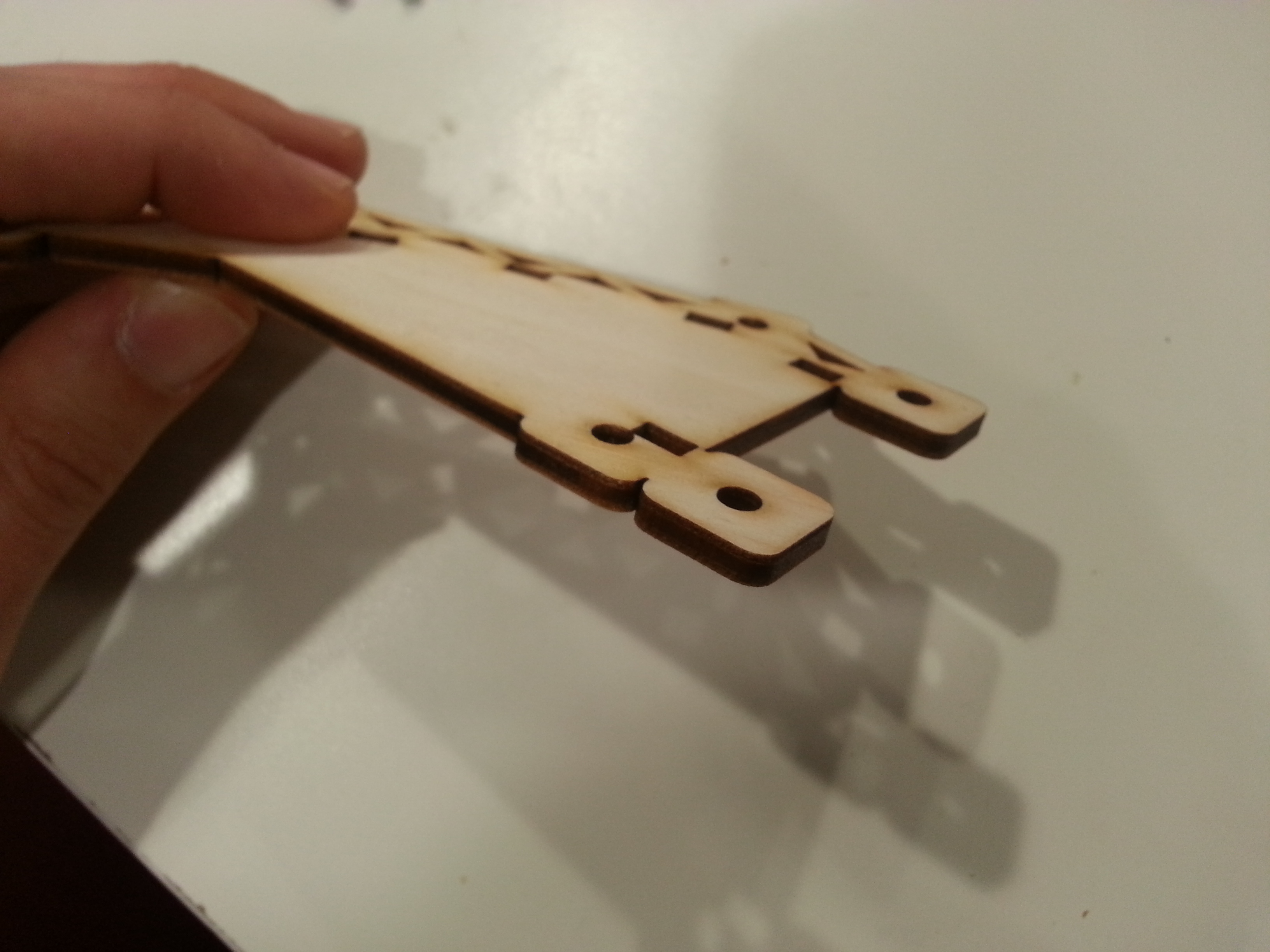

I advise you to sand the central rotating part (see photos) and rub a candle or some wa to improve the rotation.

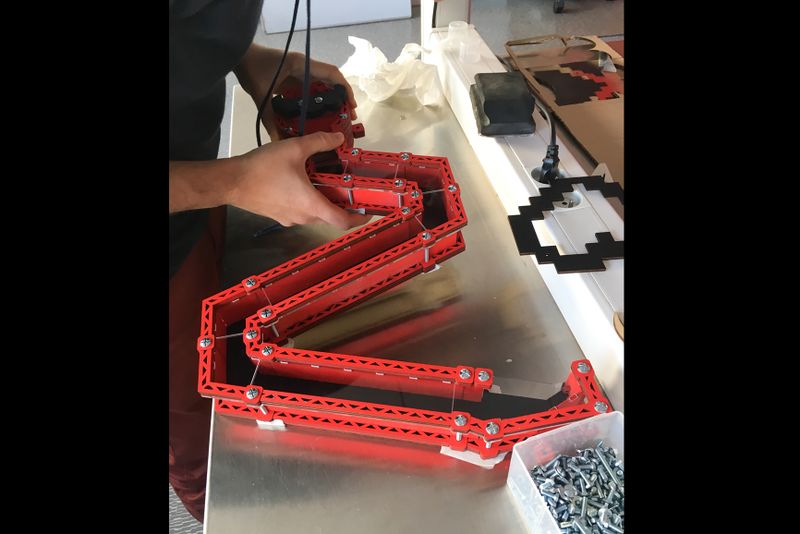

Étape 7 - "Turn" module

Laser cutting time for 1 module:

- for 3mm poplar plywood pieces: 2 minutes 24 seconds

- for 3mm transparent PMMA pieces: 14 seconds

SVG files : for plywood, for PMMA

PDF manual with help to build this module

AI file with all informations and content on different layers

Étape 8 - Small straight section

Laser cutting time for this module:

- for 3mm poplar plywood pieces: 1 minutes 21 seconds

- for 3mm transparent PMMA pieces: 13 seconds

SVG files : for plywood, for PMMA

PDF manual with help to build this module

AI file with all informations and content on different layers

Étape 9 - Long straight section

Laser cutting time for one long straight section:

- for 3mm poplar plywood pieces: 3 minutes 27 seconds

- for 3mm transparent PMMA pieces: 27 seconds

SVG files : for plywood, for PMMA

PDF manual with help to build this module

AI file with all informations and content on different layers

Étape 10 - ending module

Laser cutting time for this module:

- for 3mm poplar plywood pieces: 2 minutes 24 seconds

- for 3mm transparent PMMA pieces: 21 seconds

SVG files : for plywood, for PMMA

PDF manual with help to build this module

AI file with all informations and content on different layers

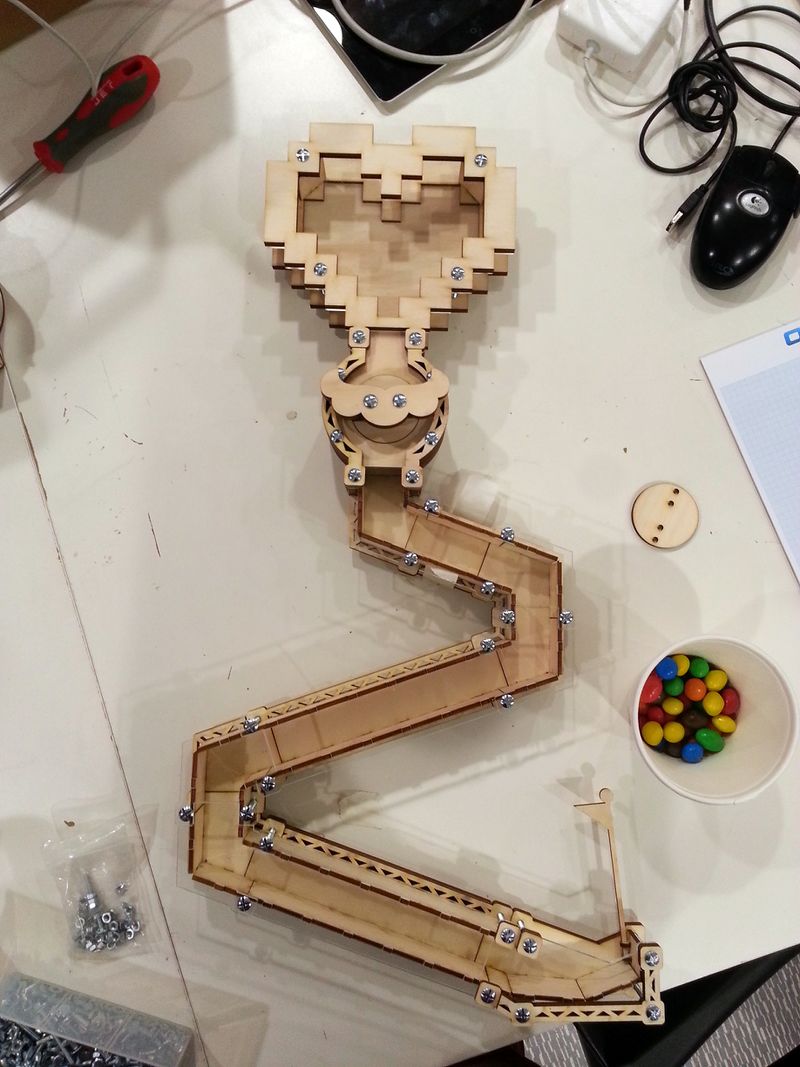

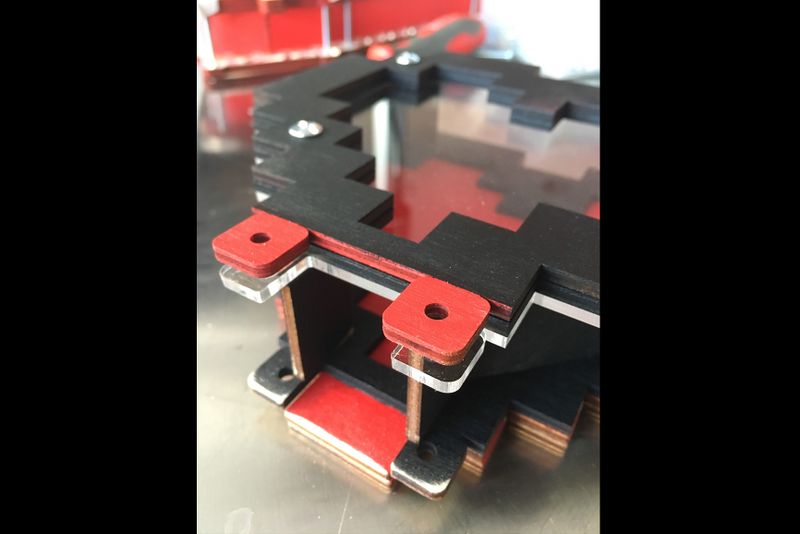

Étape 11 - Modules assembly

For the modules assembly I suggest that you refer to the PDF files.

You'll find the pieces numbering and how to assemle them (with a few additional hints)

Étape 12 - Adding some color (painting)

If you want to paint your work as I did, you'll find all the color indications in the PDFs of the modules.

Étape 13 - Level assembly

Once your different modules have been made, you can assemble them together using the 4 x 50 screws. You can see this in pictures in the video presentation of the project.

Étape 14 - Once placed on the wall...

The dispenser attaches to the wall using the mounting holes on either side of the plumber's mustache.

You'll also find one below the arrival module (see photo).

Notes et références

Created by the I-Lab of Toulon during the Trotec challenge on Wikifab.

Published

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português