(set pageLanguageSource property) |

|||

| Ligne 1 : | Ligne 1 : | ||

{{ {{tntn|Tuto Details}} | {{ {{tntn|Tuto Details}} | ||

| − | |||

| − | |||

| − | |||

|Type=Creation | |Type=Creation | ||

| − | |Area=Energy, | + | |Area=Energy, Machines and Tools |

| − | |Description= | + | |Description=This is the second tutorial for building the Pop-up Solar Generator: SunZilla 3.0. Here we are going to build the inverter and battery box |

|Difficulty=Medium | |Difficulty=Medium | ||

|Cost=128 | |Cost=128 | ||

| Ligne 13 : | Ligne 10 : | ||

|Licences=Attribution (CC BY) | |Licences=Attribution (CC BY) | ||

|Main_Picture=SunZilla_Step_07_04.jpg | |Main_Picture=SunZilla_Step_07_04.jpg | ||

| + | |SourceLanguage=none | ||

| + | |Language=en | ||

| + | |IsTranslation=0 | ||

}} | }} | ||

{{ {{tntn|Introduction}} | {{ {{tntn|Introduction}} | ||

| − | |Introduction= | + | |Introduction=Preparing the aluminium profiles |

}} | }} | ||

{{ {{tntn|Materials}} | {{ {{tntn|Materials}} | ||

| − | |Material= | + | |Step_Picture_00=SunZilla_Step_01_01.jpg |

| + | |Step_Picture_01=SunZilla_Step_01_02.jpg | ||

| + | |Material=* Black Euro-Boxes: 80€ | ||

* 4 Solar modules (à 35 Watt): 200€ | * 4 Solar modules (à 35 Watt): 200€ | ||

* Inverter victron phoenix 24/350: 153€ | * Inverter victron phoenix 24/350: 153€ | ||

| Ligne 24 : | Ligne 26 : | ||

* 2 Batteries Agm 38 yuasa: 180€ | * 2 Batteries Agm 38 yuasa: 180€ | ||

* Connectors, cables: 100€ | * Connectors, cables: 100€ | ||

| − | * Screws, Aluminium profiles, etc.: 200€ | + | * Screws, Aluminium profiles, etc.: 200€ |

|Tools=* Drills | |Tools=* Drills | ||

* Drilling machine (drill press) | * Drilling machine (drill press) | ||

| Ligne 40 : | Ligne 42 : | ||

* Silicon pistol | * Silicon pistol | ||

* Countersinking cutter | * Countersinking cutter | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

}} | }} | ||

| − | {{Separator}} | + | {{ {{tntn|Separator}}}} |

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

| − | |||

| − | |||

|Step_Picture_00=SunZilla_Step_02_01.jpg | |Step_Picture_00=SunZilla_Step_02_01.jpg | ||

| − | | | + | |Step_Title=Cut the aluminum profiles |

| − | + | |Step_Content=Cut the aluminum profiles according to the technical drawings in the attached PDFs. Once you have them in hand, the first step is to file the ends of the profiles to deburr them, as shown in the picture. | |

| − | |||

| − | | | ||

| − | |||

}} | }} | ||

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

| − | |||

| − | |||

|Step_Picture_00=SunZilla_Step_04_01.jpg | |Step_Picture_00=SunZilla_Step_04_01.jpg | ||

|Step_Picture_01=SunZilla_Step_04_02.jpg | |Step_Picture_01=SunZilla_Step_04_02.jpg | ||

|Step_Picture_02=SunZilla_Step_04_03.jpg | |Step_Picture_02=SunZilla_Step_04_03.jpg | ||

| − | | | + | |Step_Title=Mark hole's positions |

| − | | | + | |Step_Content=Mark the position of the hole you will drill with the metal marker and the ruler. For the precise location and size of the various holes in the specific profiles, refer to the technical drawings in the below PDFs. |

| − | |||

}} | }} | ||

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

| − | |||

| − | |||

| − | |||

| − | |||

|Step_Picture_00=SunZilla_Step_05_01.jpg | |Step_Picture_00=SunZilla_Step_05_01.jpg | ||

|Step_Picture_01=SunZilla_Step_05_02.jpg | |Step_Picture_01=SunZilla_Step_05_02.jpg | ||

| Ligne 79 : | Ligne 63 : | ||

|Step_Picture_04=SunZilla_Step_06_01.jpg | |Step_Picture_04=SunZilla_Step_06_01.jpg | ||

|Step_Picture_05=SunZilla_Step_06_02.jpg | |Step_Picture_05=SunZilla_Step_06_02.jpg | ||

| + | |Step_Title=Drill holes with the drill press | ||

| + | |Step_Content=Afterwards, the marked positions need to be punched with the centre punch and then the holes can be drilled with the drill press. | ||

| + | |||

| + | After the holes are drilled they also need to be deburred by a countersinking cutter. | ||

}} | }} | ||

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

| − | |Step_Title= | + | |Step_Picture_00=SunZilla_Step_07_01.jpg |

| + | |Step_Picture_01=SunZilla_Step_07_02.jpg | ||

| + | |Step_Picture_02=SunZilla_Step_07_03.jpg | ||

| + | |Step_Picture_03=SunZilla_Step_07_04.jpg | ||

| + | |Step_Title=Cut open on one side | ||

|Step_Content=For the 4 x 150mm long square profiles, you should use the .PDF technical drawing "Folding Mech.- slides.pdf". | |Step_Content=For the 4 x 150mm long square profiles, you should use the .PDF technical drawing "Folding Mech.- slides.pdf". | ||

| Ligne 87 : | Ligne 79 : | ||

These will be cut open on one side like on the first picture beside. | These will be cut open on one side like on the first picture beside. | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

}} | }} | ||

| − | {{ {{tntn|Notes}}|}} | + | {{ {{tntn|Notes}} |

| + | |Notes= | ||

| + | }} | ||

| + | {{ {{tntn|Tuto Status}}}} | ||

Version du 22 septembre 2017 à 17:33

Introduction

Matériaux

- Black Euro-Boxes: 80€

- 4 Solar modules (à 35 Watt): 200€

- Inverter victron phoenix 24/350: 153€

- Charge Controller: blue solar 100/15: 115€

- 2 Batteries Agm 38 yuasa: 180€

- Connectors, cables: 100€

- Screws, Aluminium profiles, etc.: 200€

Outils

- Drills

- Drilling machine (drill press)

- Wrenches

- Soldering station

- Pliers

- Aluminium file

- Centre punch

- Rubber and metal hammers

- Ruler

- Set square

- Marker pen

- Mitre saw (for aluminium)

- Milling cutter

- Silicon pistol

- Countersinking cutter

Étape 1 - Cut the aluminum profiles

Cut the aluminum profiles according to the technical drawings in the attached PDFs. Once you have them in hand, the first step is to file the ends of the profiles to deburr them, as shown in the picture.

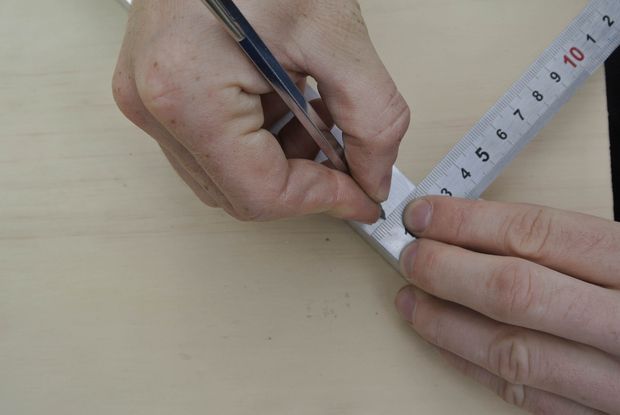

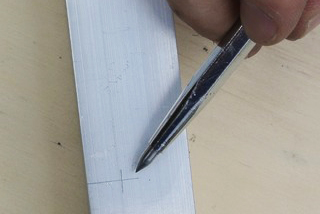

Étape 2 - Mark hole's positions

Mark the position of the hole you will drill with the metal marker and the ruler. For the precise location and size of the various holes in the specific profiles, refer to the technical drawings in the below PDFs.

Étape 3 - Drill holes with the drill press

Afterwards, the marked positions need to be punched with the centre punch and then the holes can be drilled with the drill press.

After the holes are drilled they also need to be deburred by a countersinking cutter.

Étape 4 - Cut open on one side

For the 4 x 150mm long square profiles, you should use the .PDF technical drawing "Folding Mech.- slides.pdf".

These will be cut open on one side like on the first picture beside.

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português