|

|

| Ligne 304 : |

Ligne 304 : |

| | #Layout the remaining pies as seen in image 1. | | #Layout the remaining pies as seen in image 1. |

| | #Slide plate 1110.08 directly on top of piece 1110.07 | | #Slide plate 1110.08 directly on top of piece 1110.07 |

| − | #Drop in plate 1110.09 directly next to 1110.07/.08 in the open tabs. | + | #Drop in plate 1110.09 directly next to 1110.07/.08 in the open tabs. |

| | #Place the bottom tabs of plate 1110.10 into the bottom plate, and then fold the plate upwards into place. | | #Place the bottom tabs of plate 1110.10 into the bottom plate, and then fold the plate upwards into place. |

| | #Place plate 1110.11 on top as seen in image 5. | | #Place plate 1110.11 on top as seen in image 5. |

| − | #Place plate 1110.01 on top, securing the entire box in place. | + | #Place plate 1110.01 on top, securing the entire box in place. |

| | + | |

| | + | <nowiki>*</nowiki>Note - in the next steps, you will dismantle these last few steps, but it is important to understand how the box comes together. |

| | | | |

| | <br /></translate> | | <br /></translate> |

| Ligne 320 : |

Ligne 322 : |

| | |Step_Picture_04=PP_Shredder_Pro_PXL_20211020_213606954.jpg | | |Step_Picture_04=PP_Shredder_Pro_PXL_20211020_213606954.jpg |

| | |Step_Picture_05=PP_Shredder_Pro_PXL_20211020_213732491.jpg | | |Step_Picture_05=PP_Shredder_Pro_PXL_20211020_213732491.jpg |

| | + | }} |

| | + | {{Tuto Step |

| | + | |Step_Title=<translate>Tapping bearing holes</translate> |

| | + | |Step_Content=<translate>====Tools==== |

| | + | M16 x 2 Tap |

| | + | |

| | + | Tapping oil(optional but recommended) |

| | + | |

| | + | 2 medium/large clamps |

| | + | ====Parts==== |

| | + | 4 M16 x 40mm Socket head cap bolts |

| | + | |

| | + | 4 M16 washers |

| | + | |

| | + | Shredder box assembly |

| | + | <br /> |

| | + | |

| | + | ==== Steps ==== |

| | + | |

| | + | # Remove the top plate from Step 8 above. |

| | + | # Secure parts 1110.05/.06 (Left end of shredder box) using 2 C-clamps. |

| | + | ## *Be sure to leave yourself room to turn the tap. |

| | + | ## *It is important to have a tight fit. If your steel parts have burs or scratches that prevent a tight connection, remove those first! |

| | + | # For each hole, tap both plates in one consecutive operation. Remove burrs and clean the hole. |

| | + | # Check the hole by securing the M16 bolts.</translate> |

| | + | |Step_Picture_00=PP_Shredder_Pro_PXL_20211020_214420936.jpg |

| | + | |Step_Picture_01=PP_Shredder_Pro_PXL_20211020_214434621.jpg |

| | + | |Step_Picture_02=PP_Shredder_Pro_PXL_20211020_214605605.jpg |

| | + | |Step_Picture_03=PP_Shredder_Pro_PXL_20211020_214721535.jpg |

| | + | |Step_Picture_04=PP_Shredder_Pro_PXL_20211020_214934580.jpg |

| | + | |Step_Picture_05=PP_Shredder_Pro_PXL_20211020_223602337.jpg |

| | }} | | }} |

| | {{Notes | | {{Notes |

This tutorial documents the build process of Precious Plastic Pro Shredder, as supplied by Citizen Scientific for the North American context.

Auteur  PPatASU | Dernière modification 29/11/2021 par PPatASU

PPatASU | Dernière modification 29/11/2021 par PPatASU

Difficulté

Hard Difficile

Catégories

Machines & Outils, Recyclage & Upcycling, Robotique

This tutorial documents the build process of Precious Plastic Pro Shredder, as supplied by Citizen Scientific for the North American context.

Difficulté

Hard Difficile

Catégories

Machines & Outils, Recyclage & Upcycling, Robotique

preciousplastic, recycling, Open Source, plastic, shredder

Creation

Étape 1 - Tools

Hammer

(punch) for knocking out leftover metal slugs

Files

Mallet

Socket wrench( 2x)

Tape measure

Screwdriver (directing the slide nuts)

Marker

Étape 2 - Table Parts

Parts Needed:

Aluminum Extrusion

| Profile

| Length (mm)

| Quantity

|

| 8080

| 520

| 4

|

| 8080

| 600

| 4

|

| 8080

| 1200

| 2

|

| 4080

| 520

| 1

|

| 4080

| 455

| 1

|

| data-sheets-value="{"1":2,"2":"Corner Plates"}"

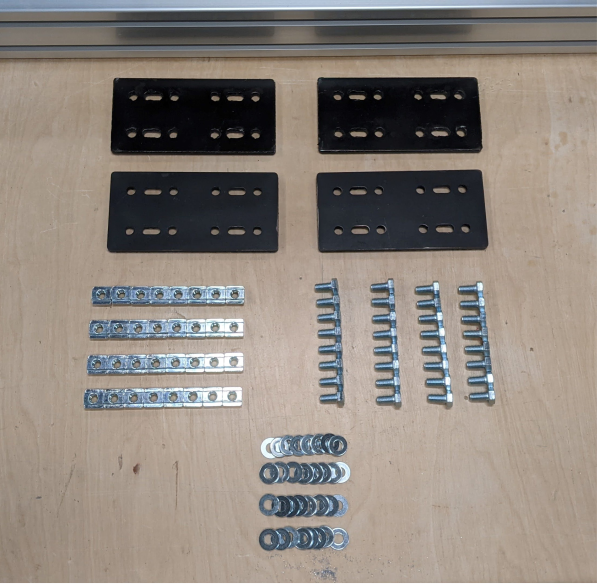

Étape 3 - Table Construction - Legs

Tools

XX Socket Wrench

Screwdriver

Parts

4x 8080*600mm

2x 8080*1200mm

4x Side Plates

32x T nuts

32x Washers

32x M8x16mm Bolts

Steps

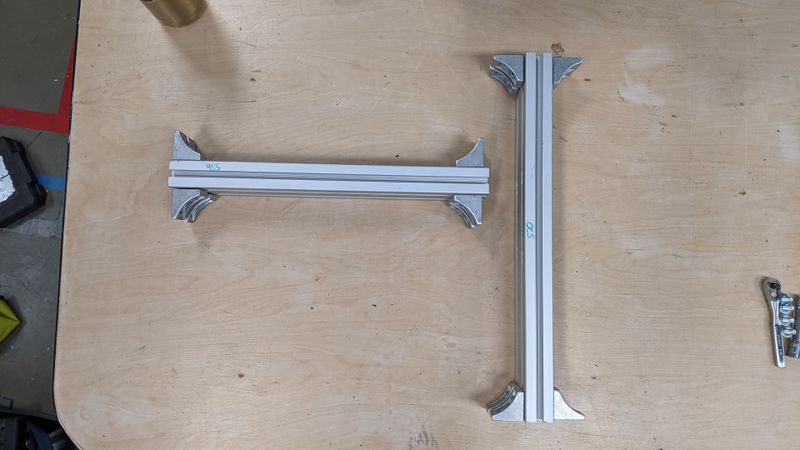

- Lay one 1200mm beam horizontally in your workspace. Add a 600mm beam perpendicular at each end, forming a staple shape. (see image 5 for final shape reference)

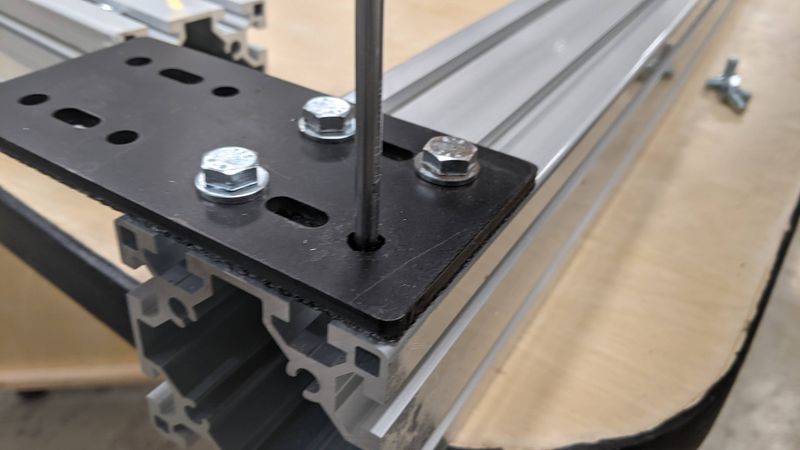

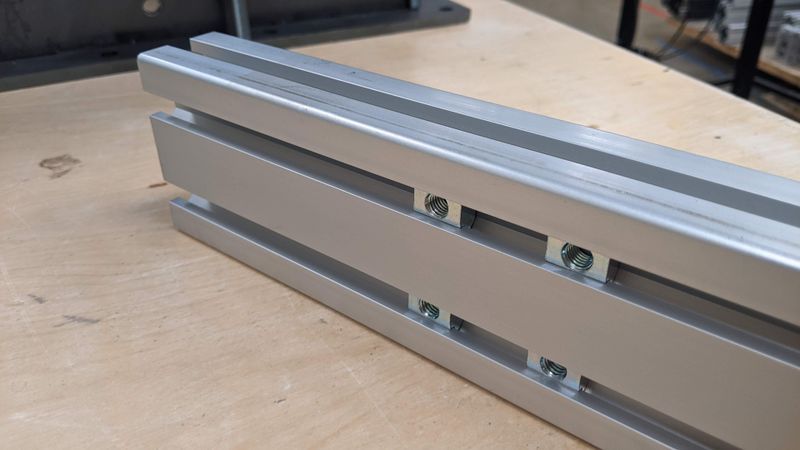

- Using 8 total washers, slide 2 at a time into each rail at the corner, approximating the hole pattern on the side plates. (image 2)

- Using a screwdriver to position the T-nuts, add an M8x16 Bolt and washer through the side plate into each T nut. (images 3 and 4)

- Secure with a socket wrench. Repeat on the other side of the 1200mm beam.

You now have a staple shape. Repeat.

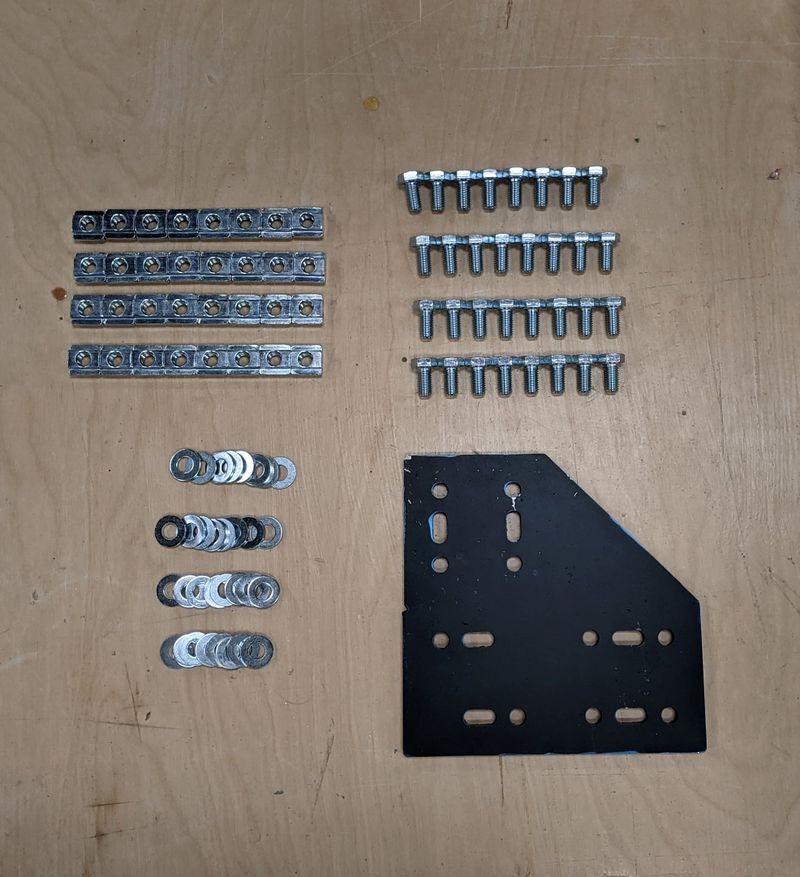

Étape 4 - Table Construction - Side Joints

Tools

XX Socket Wrench

Screwdriver

Parts

2x 8080*520mm

4x Corner Plates

44x T nuts

32x Washers

32x M8x16mm Bolts

Steps

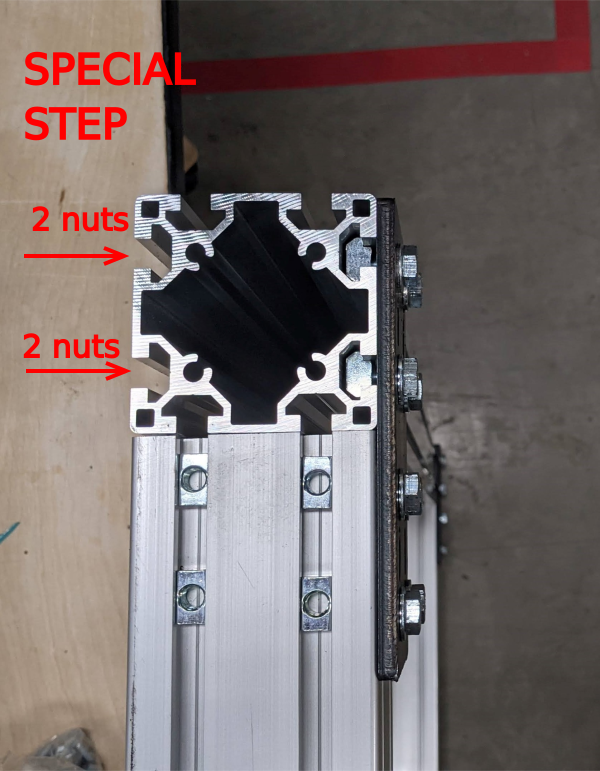

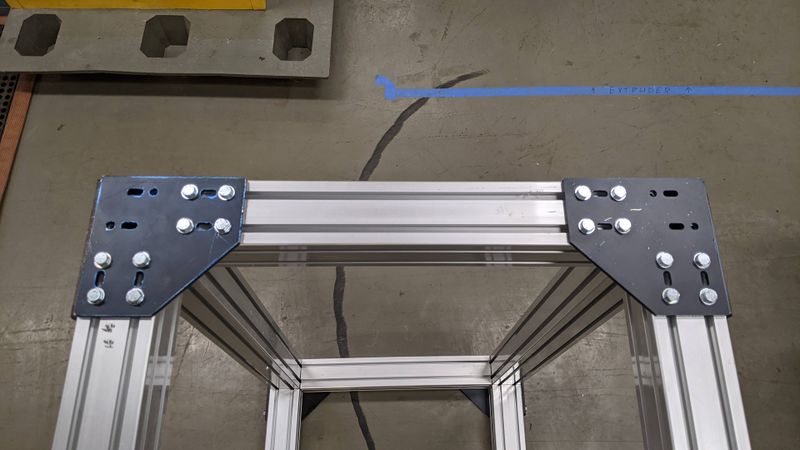

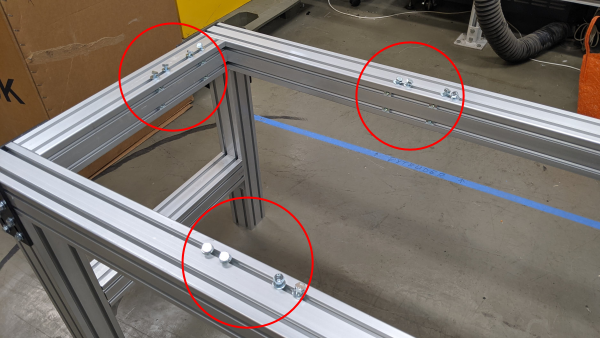

- Stand one leg unit upward, so you can see down the 1200mm section. Slide 4 T-nuts total (2 in each rail) up to the corner joint. (image 2)

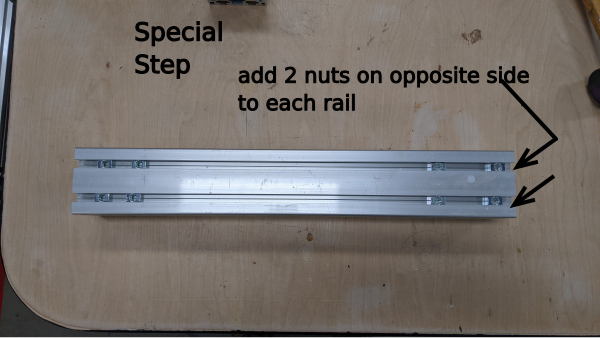

- SPECIAL STEP: on the 1200mm beam, opposite side from where the side plate was installed - Slide 2 nuts into each of the rails. These will be used in a future step. Repeat on the other 1200mm beam.

- Attach the side plate (image 3) using 4 M8x16 Bolts with 4 washers.

- NOTE: the 45° side should face the "bottom" of the eventual table.

- Repeat on the remaining three 600mm legs.

- NOTE: ensure that each corner plate mirrors each other across the 1200mm beam axis. They should be facing the same direction and away from the side plate from the previous step.

- Slide 8 total T-nuts into a 520mm beam. They should be split in half, 4 at one end, and 4 at the other. (Image 4)

- SPECIAL STEP: On only ONE of the 520mm beams, add 4 T-nuts, 2 in each rail on the opposite side that you used for Step 5.

- Combine the two "staple" sections by adding the 520mm beam (pre-loaded with T-nuts) using the same M8x16mm, washer combination as before. (image 5)

- Repeat on the other side. (image 6)

You should now have a very solid table base!

Étape 5 - Table Construction - Side Braces

Tools

XX Socket Wrench

Screwdriver

Parts

2x 8080*520mm

8x Brackets

16x T nuts

16x Washers

16x M8x20mm Bolts

*A quick note about bracket orientation. In image 2 you will see that the brackets are not the same on both sides. Here we have flipped one, so you can see the difference. One of the holes sits atop a raised lip, while the other is flush. The raised lip hole is closer to the brackets outside edge. The flush hole is farther from the outside edge. This matters for order of operations. When installing, you must install in the flush hole first, and the hole with the raised lip second. If you do it in reverse the bolt will block access to the other hole. :)

Steps

- Slide 4 nuts into the 520mm beam (2 in each rail).

- Attach the 4 brackets loosely using M8x20mm bolts and washers. (image 3)

- Note the orientation of the holes. All 4 bolts should go in flush holes, not raised lip holes. (figure 4)

- With the table flipped on its end, position the 520mm beam in place, and slide 2 T-nuts in the rails to meet the brackets. Secure with same M8x20 bolt washer combo.

- Repeat this process on the other side of the 520mm beam.

- Repeat steps 1-4 on the opposite side of table.

Étape 6 - Table Construction - Center Struts

Tools

XX Socket Wrench

Screwdriver

Parts

1x 4080*520mm

1x 4080*455mm

16 Brackets

20x T nuts

32x Washers

32x M8x16mm Bolts

*Construction note: Until the very end, keep ALL of these bolt joints LOOSE. They will need to slide around to get everything in place. Once the location has been set, then you can tighten them down.

Steps

- Insert 4 T-nuts (2 in each rail) on one side of the 520mm 4080 (image1 )

- For both beams, attach brackets (using the flush hole) at all 8 corners. (image 2)

- Arrange the beams so the 520mm beam is vertical, and the 455mm beam is horizontal, intersecting near the middle of the 520mm beam on the left hand side.

- Loosely attach the horizontal beam to the vertical beam. (images 3 and 4)

- Remember all those T-nuts we hid in the frame in step 4? Now we are going to connect this sub-assembly to them.

- Place 4 bolt/washer combos at each of the 3 locations designated in image 5.

- Drop the sub-assembly into the table frame, and loosely connect the brackets into the pre-loaded T-nuts

- This is easier with 2 people.

- You only need 1 bolt at each of the three locations to hold the weight of the sub-assembly.

- After those first three bolts are in, you can easily go back and connect the others.

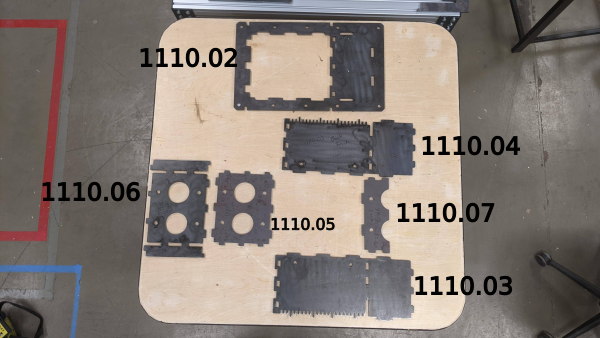

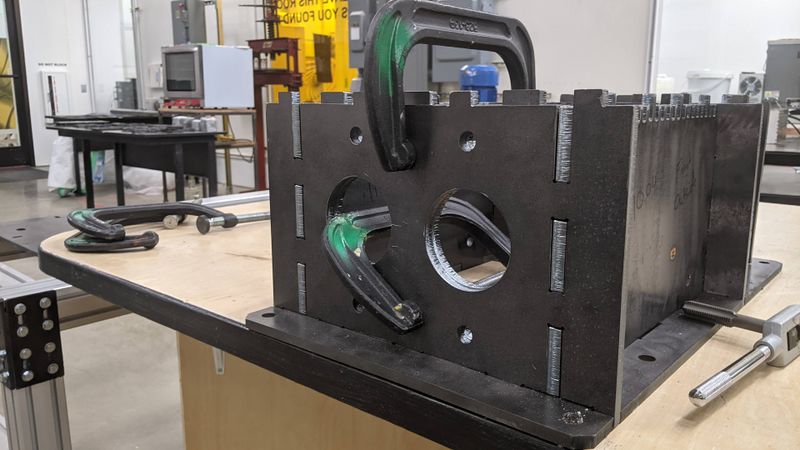

Étape 7 - Shredder Box Layout 1

Tools

none

Parts

1110.02 - Bottom Plate Box

1110.03 - Fixed Blades plate 1

1110.04 - Fixed Blades plate 2

1110.05 - Bearing Side Plate 1

1110.06 - Bearing Side Plate 2

1110.07 - Bearing Side Plate 3

*this is much easier with two people to hold the plates before they are locked into position. It is also heavy metal, and a dropped plate is enough to cause injury.

Steps

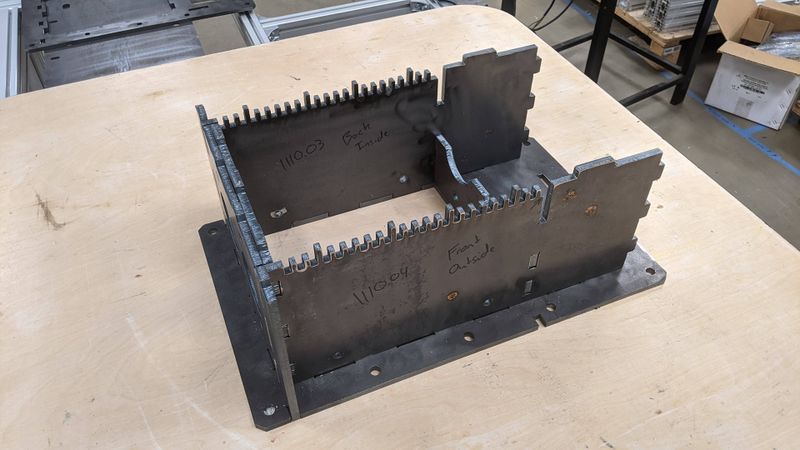

- Layout the parts as seen in image 1, ensuring that the fixed blade plates are mirrored.

- Teeth should be pointing away from each other.

- Fold up both plates so the teeth point upwards while your helper inserts the tabs from pieces 1110.07 and 1110.05. You should now have a 4 walled box as seen in image 2.

- Fold up plate 1110.06 to meet the left end of the box.

- CAREFULLY slide the bottom plate underneath this sub-assembly, aligning the tabs until it drops into place.

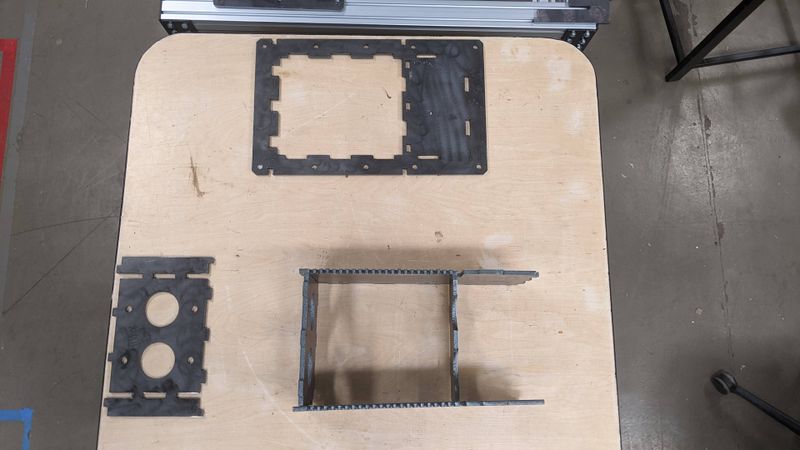

Étape 8 - Shredder Box Layout 2

Tools

none

Parts

1110.08 - Bearing Side Plate 4

1110.09 - Bearing Side Plate 5

1110.10 - Bearing Side Plate 6

1110.11 - Gear Plate

1110.01 - Top Plate

Steps

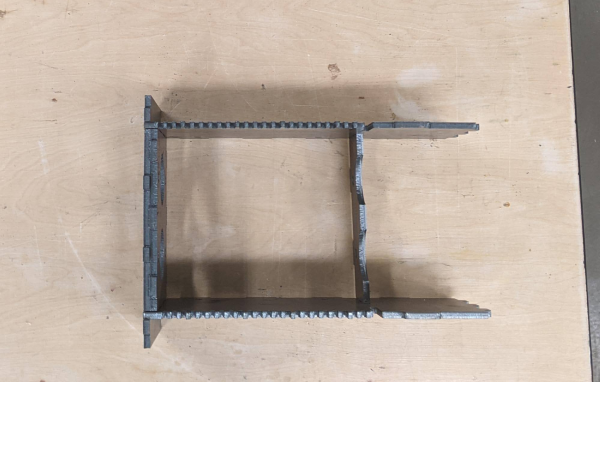

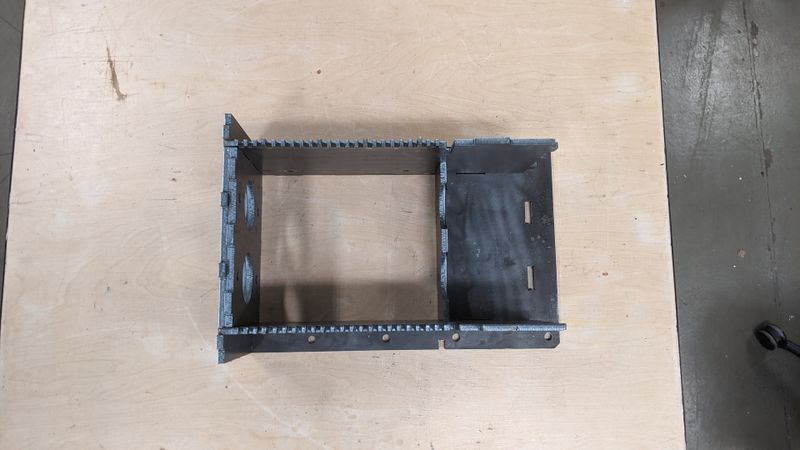

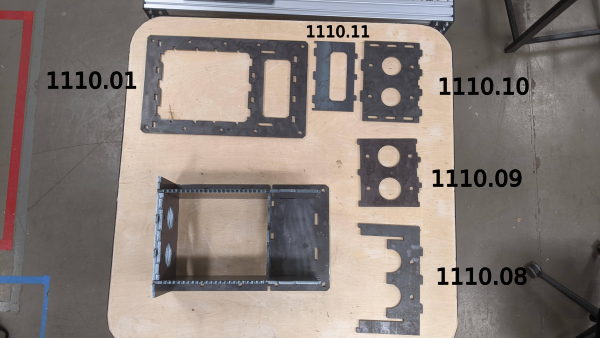

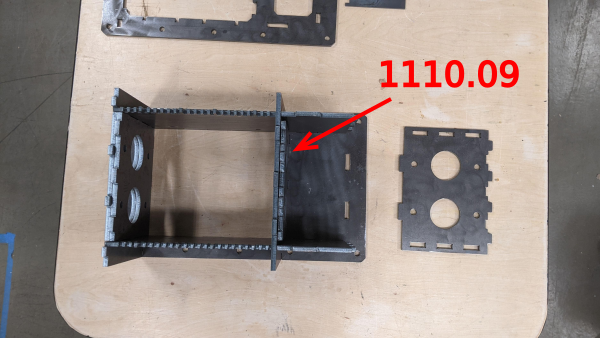

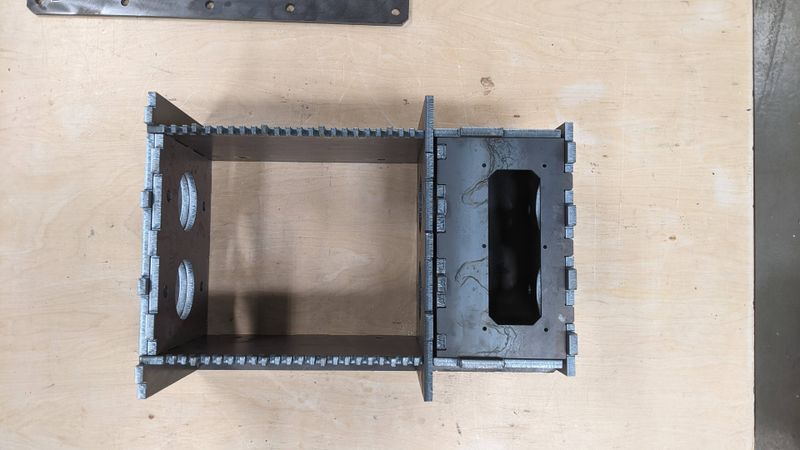

- Layout the remaining pies as seen in image 1.

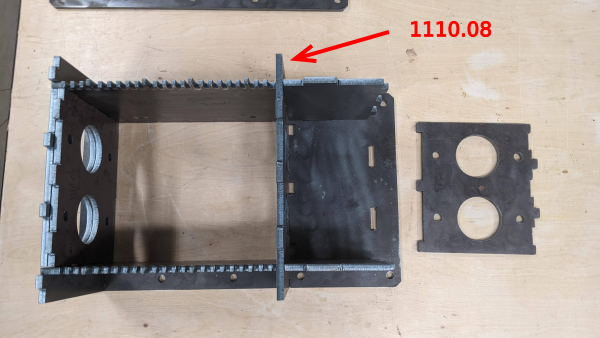

- Slide plate 1110.08 directly on top of piece 1110.07

- Drop in plate 1110.09 directly next to 1110.07/.08 in the open tabs.

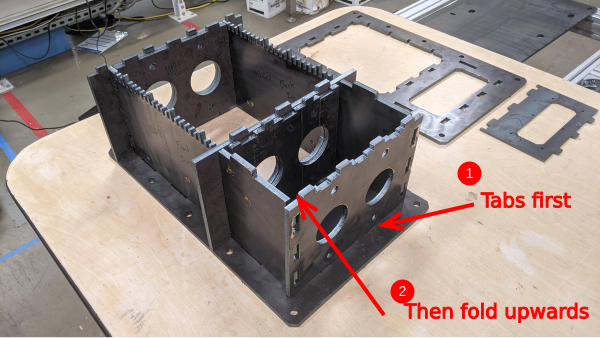

- Place the bottom tabs of plate 1110.10 into the bottom plate, and then fold the plate upwards into place.

- Place plate 1110.11 on top as seen in image 5.

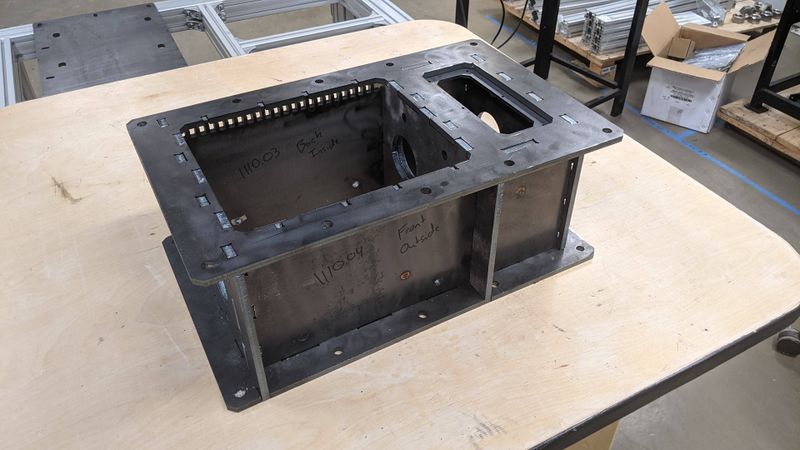

- Place plate 1110.01 on top, securing the entire box in place.

*Note - in the next steps, you will dismantle these last few steps, but it is important to understand how the box comes together.

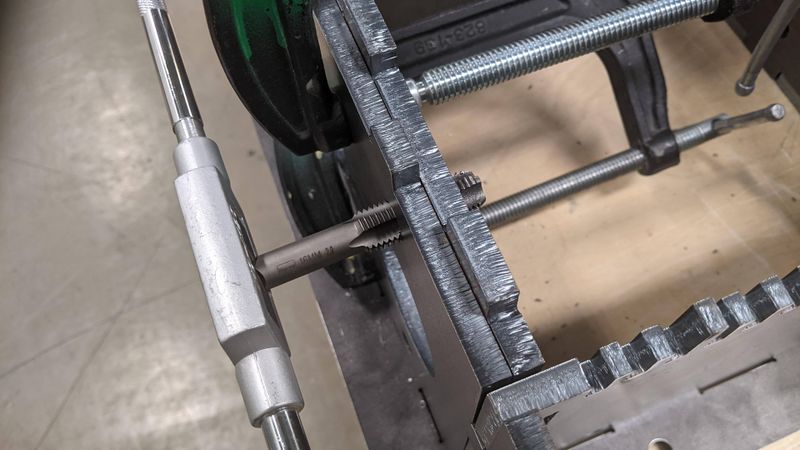

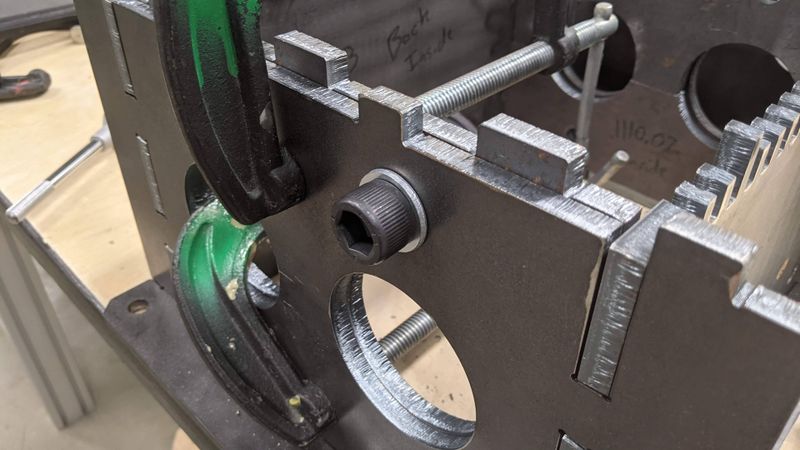

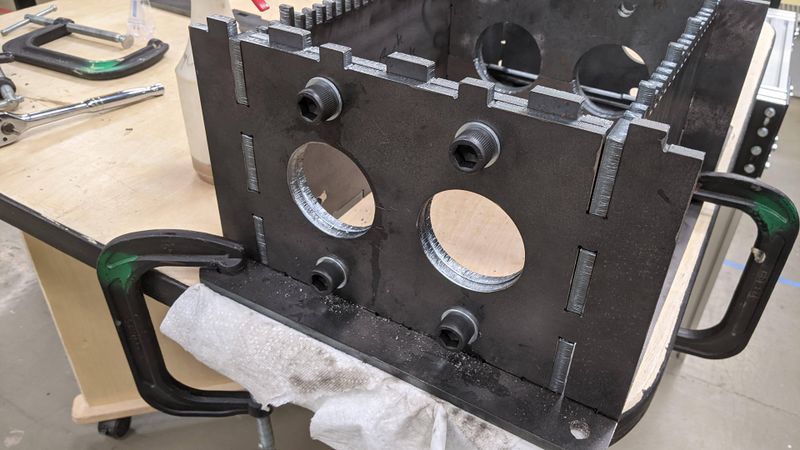

Étape 9 - Tapping bearing holes

Tools

M16 x 2 Tap

Tapping oil(optional but recommended)

2 medium/large clamps

Parts

4 M16 x 40mm Socket head cap bolts

4 M16 washers

Shredder box assembly

Steps

- Remove the top plate from Step 8 above.

- Secure parts 1110.05/.06 (Left end of shredder box) using 2 C-clamps.

- *Be sure to leave yourself room to turn the tap.

- *It is important to have a tight fit. If your steel parts have burs or scratches that prevent a tight connection, remove those first!

- For each hole, tap both plates in one consecutive operation. Remove burrs and clean the hole.

- Check the hole by securing the M16 bolts.

en

none

0

Published

|

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português