| Ligne 95 : | Ligne 95 : | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate>Table Construction</translate> | + | |Step_Title=<translate>Table Construction - Legs</translate> |

| − | |Step_Content=<translate>==== Tools | + | |Step_Content=<translate>====Tools==== |

XX Socket Wrench | XX Socket Wrench | ||

Screwdriver | Screwdriver | ||

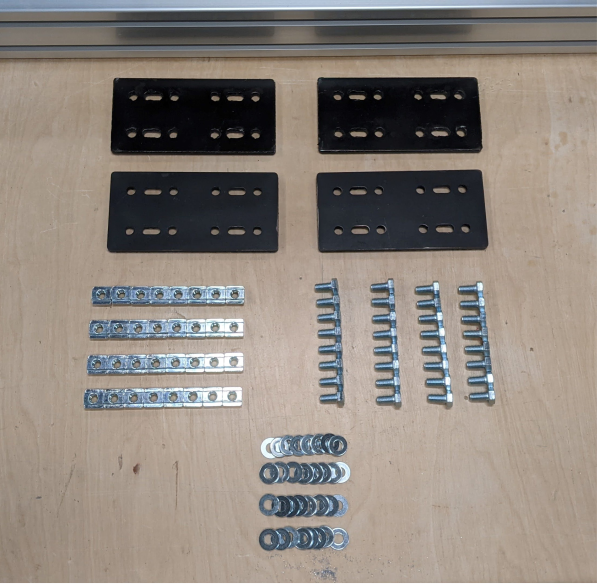

| − | ==== Parts | + | ====Parts==== |

4x 8080*600mm | 4x 8080*600mm | ||

| Ligne 114 : | Ligne 114 : | ||

32x M8x16mm Bolts | 32x M8x16mm Bolts | ||

| − | ==== Steps ==== | + | ====Steps==== |

| − | # Lay one 1200mm beam horizontally in your workspace. Add a 600mm beam perpendicular at each end, forming a staple shape. (see image 5 for final shape reference) | + | #Lay one 1200mm beam horizontally in your workspace. Add a 600mm beam perpendicular at each end, forming a '''staple shape.''' (see image 5 for final shape reference) |

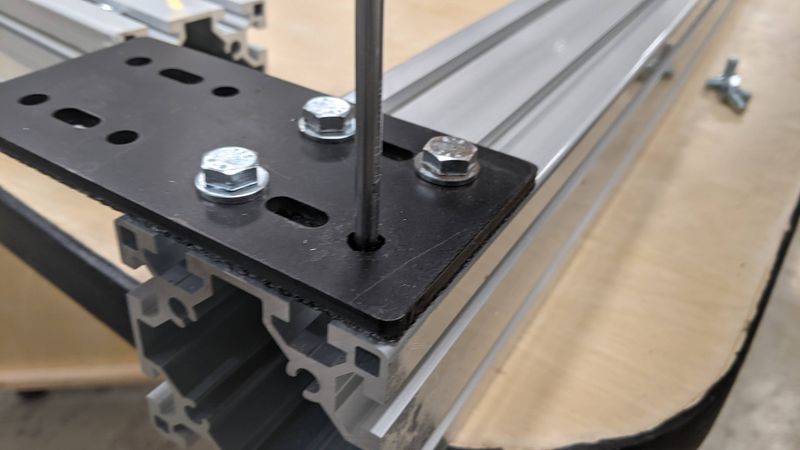

| − | # Using 8 total washers, slide 2 at a time into each rail at the corner, approximating the hole pattern on the side plates. (image 2) | + | #Using 8 total washers, slide 2 at a time into each rail at the corner, approximating the hole pattern on the side plates. (image 2) |

| − | # Using a screwdriver to position the T-nuts, add an M8x16 Bolt and washer through the side plate into each T nut. (images 3 and 4) | + | #Using a screwdriver to position the T-nuts, add an M8x16 Bolt and washer through the side plate into each T nut. (images 3 and 4) |

| − | # Secure with a socket wrench. Repeat on the other side of the 1200mm beam. | + | #Secure with a socket wrench. Repeat on the other side of the 1200mm beam. |

| + | # | ||

<br /></translate> | <br /></translate> | ||

| Ligne 128 : | Ligne 129 : | ||

|Step_Picture_03=PP_Shredder_Pro_PXL_20210913_180527698.MP.jpg | |Step_Picture_03=PP_Shredder_Pro_PXL_20210913_180527698.MP.jpg | ||

|Step_Picture_04=PP_Shredder_Pro_PXL_20210913_183936869.MP.jpg | |Step_Picture_04=PP_Shredder_Pro_PXL_20210913_183936869.MP.jpg | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Table Construction - Side Joints</translate> | ||

| + | |Step_Content=<translate>====Tools==== | ||

| + | XX Socket Wrench | ||

| + | |||

| + | Screwdriver | ||

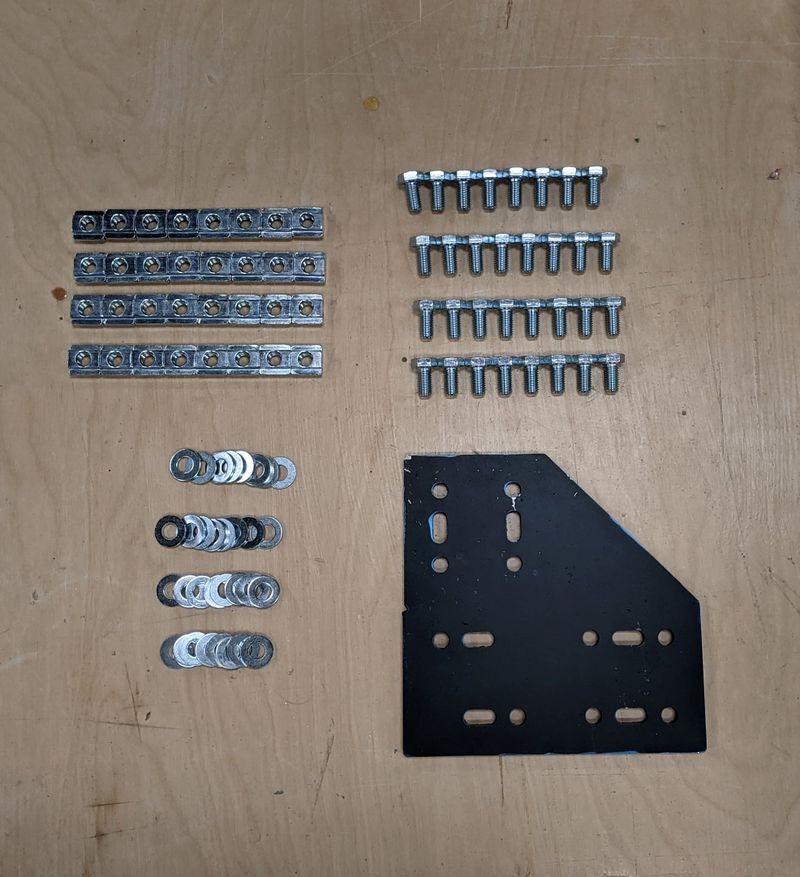

| + | ====Parts==== | ||

| + | 2x 8080*520mm | ||

| + | |||

| + | 4x Corner Plates | ||

| + | |||

| + | 32x T nuts | ||

| + | |||

| + | 32x Washers | ||

| + | |||

| + | 32x M8x16mm Bolts | ||

| + | ====Steps==== | ||

| + | |||

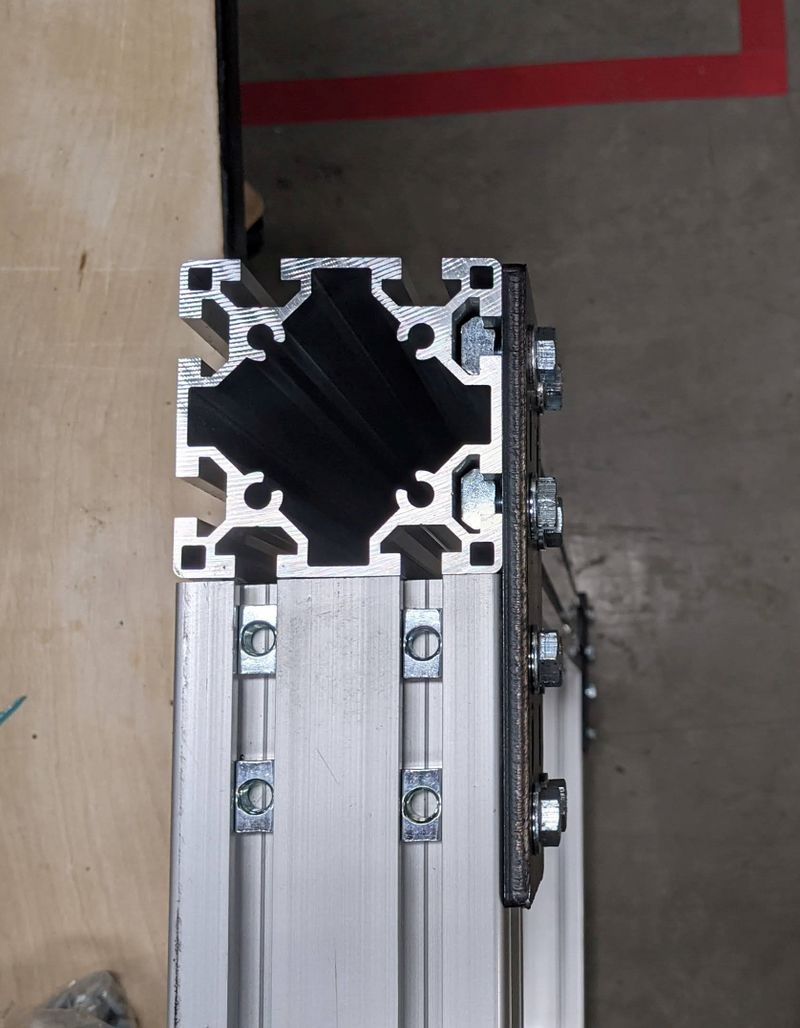

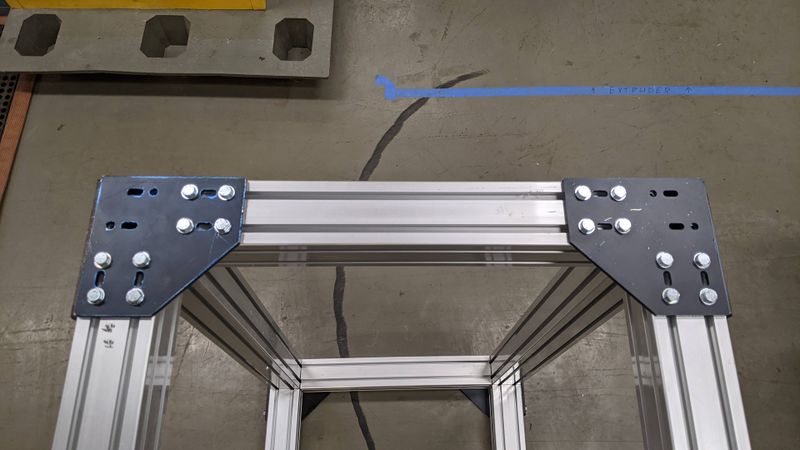

| + | #Stand one leg unit upward, so you can see down the 1200mm section. Slide 4 T-nuts total (2 in each rail) up to the corner joint. (image 2) | ||

| + | #Attach the side plate (image 3) using 4 M8x16 Bolts with 4 washers. | ||

| + | ##NOTE: the 45° side should face the "bottom" of the eventual table. | ||

| + | #Repeat on the remaining three 600mm legs. | ||

| + | ##NOTE: ensure that each corner plates '''mirror''' each other across the 1200mm beam axis. They should be facing the same direction. | ||

| + | #Slide 8 total T-nuts into a 520mm beam. They should be split in half, 4 at one end, and 4 at the other. (Image 4) | ||

| + | #Combine the two "'''staple'''" sections by adding the 520mm beam (pre-loaded with T-nuts) using the same M8x16mm, washer combination as before. (image 5) | ||

| + | #Repeat on the other side. (image 6) | ||

| + | |||

| + | You should now have a very solid table base!</translate> | ||

| + | |Step_Picture_00=PP_Shredder_Pro_1PXL_20210913_183647758.MP.jpg | ||

| + | |Step_Picture_01=PP_Shredder_Pro_1PXL_20210913_184210669.MP.jpg | ||

| + | |Step_Picture_02=PP_Shredder_Pro_1PXL_20210913_184439835.MP.jpg | ||

| + | |Step_Picture_03=PP_Shredder_Pro_PXL_20210913_184424674.MP.jpg | ||

| + | |Step_Picture_04=PP_Shredder_Pro_PXL_20210913_190202336.MP.jpg | ||

| + | |Step_Picture_05=PP_Shredder_Pro_PXL_20210913_190407012.MP.jpg | ||

}} | }} | ||

{{Notes | {{Notes | ||

Version du 12 octobre 2021 à 23:57

This tutorial documents the build process of Precious Plastic Pro Shredder, as supplied by Citizen Scientific for the North American context.

Difficulté

Difficile

Durée

5 jour(s)

Catégories

Machines & Outils, Recyclage & Upcycling, Robotique

Coût

5000 USD ($)

Matériaux

Outils

Étape 1 - Tools

Hammer

(punch) for knocking out leftover metal slugs

Files

Mallet

Socket wrench( 2x)

Tape measure

Screwdriver (directing the slide nuts)

Marker

Étape 2 - Table Parts

Parts Needed:

Aluminum Extrusion

| Profile | Length (mm) | Quantity |

|---|---|---|

| 8080 | 520 | 4 |

| 8080 | 600 | 4 |

| 8080 | 1200 | 2 |

| 4080 | 520 | 1 |

| 4080 | 455 | 1 |

| data-sheets-value="{"1":2,"2":"Corner Plates"}"

Étape 3 - Table Construction - LegsToolsXX Socket Wrench Screwdriver Parts4x 8080*600mm 2x 8080*1200mm 4x Side Plates 32x T nuts 32x Washers 32x M8x16mm Bolts Steps

Étape 4 - Table Construction - Side JointsToolsXX Socket Wrench Screwdriver Parts2x 8080*520mm 4x Corner Plates 32x T nuts 32x Washers 32x M8x16mm Bolts Steps

You should now have a very solid table base!

Draft |

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português