Sommaire

- 1 Étape 1 - Table Build-Top deck 1

- 2 Étape 2 - Table Build- Top deck 2

- 3 Étape 3 - Table Build- Top deck 3

- 4 Étape 4 - Table Build - Side Legs 1

- 5 Étape 5 - Table Build - Side Legs 2

- 6 Étape 6 - Table Build - Tapping beams

- 7 Étape 7 - Barrel Support 1

- 8 Étape 8 - Barrel Support 2

- 9 Étape 9 - Barrel/Shaft/Bearings

- 10 Commentaires

Matériaux

Outils

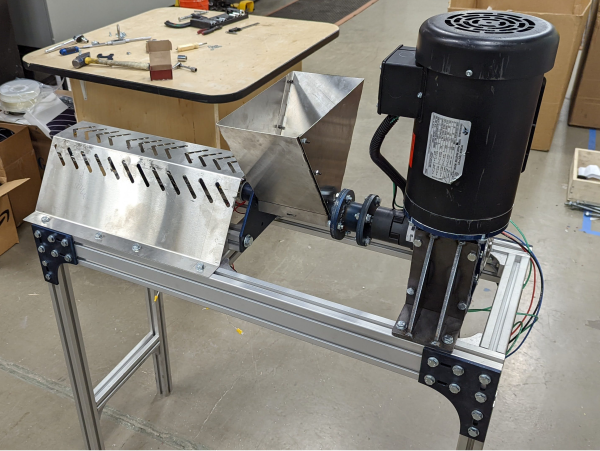

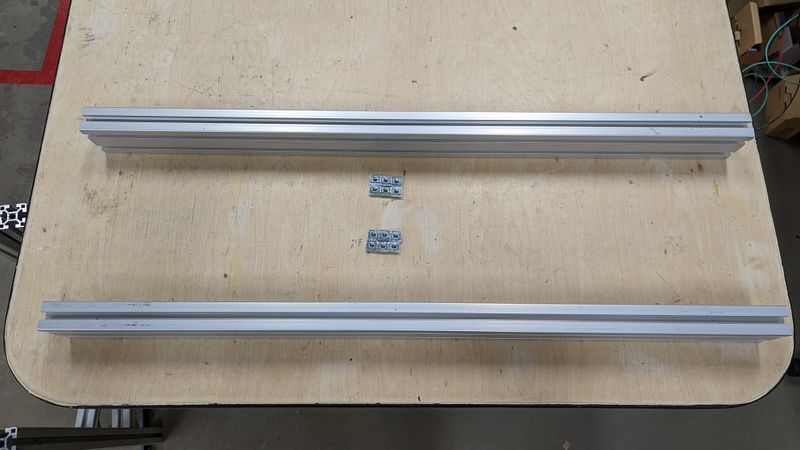

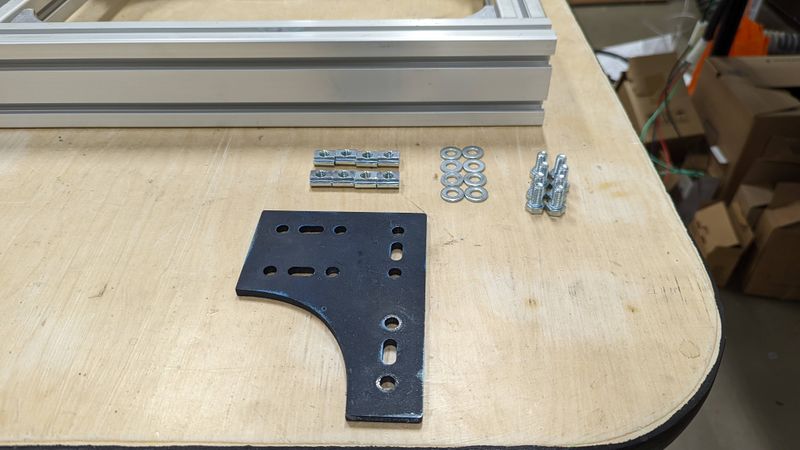

Étape 1 - Table Build-Top deck 1

Tools

1/2" Socket

Parts

2x 1000mm 4080 extrusion

4x 300mm 4040 extrusion

40x t-nuts

22x M8x20 bolts

22x M8 Washers

12x Corner Brackets

Steps

- Slide 6 t nuts into the top side of the 1000mm extrusion. (repeat for other beam)

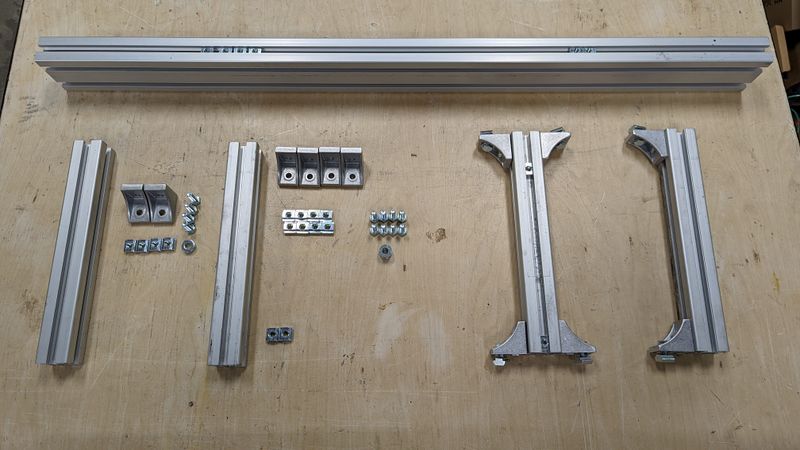

- For the 300mm beams, 2 pairs of 2 will be identical, one "I" shaped, and one "C" shaped.

- For the C-shaped beam, Slide two t-nuts into one rail. Attach the corner brackets at the ends, ensuring the bracket is flush with the beams end. *Always use the side of the bracket with a flat face (non-lipped) first. This ensures you can get a tool onto the 2nd bolt without being blocked.

- For the I-Beams, repeat the same steps for the C-beam, but on both sides.

- Repeat so you have 2 I-beams and 2-C beams.

- *Optional* Add bolts to all remaining bracket holes and loosely attach t-nuts. (as seen in the right two beams in image 3)

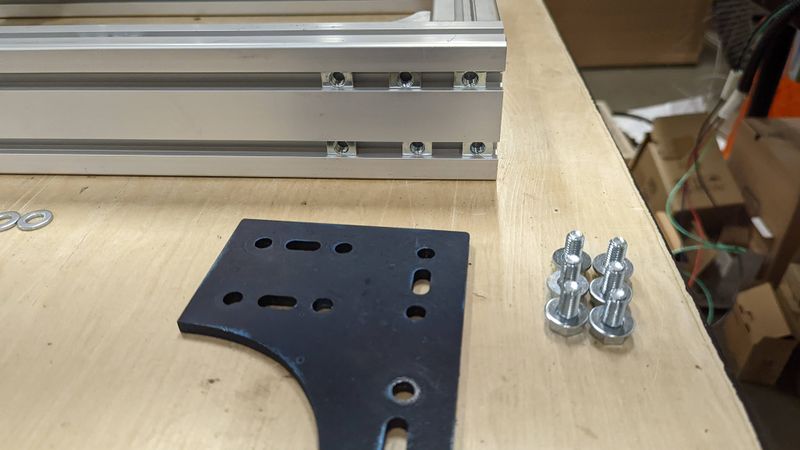

Étape 2 - Table Build- Top deck 2

Tools

1/2" Socket Wrench

Parts

Assemblies from previous step

Steps

- If you have already attached the bolts/and t-nuts from the optional step - Slide beams into the upper channel (as seen in image 1) Otherwise, thread the nuts into the channel and attach LOOSELY with bolts.

- Repeat for the bottom rail.

- Secure the C beams in place with the socket wrench, but leave the I-beams LOOSE as they will need to be shifted later.

Étape 3 - Table Build- Top deck 3

Tools

1/2" Socket Wrench

Parts

Assembly from previous step

4x Steel Corner Brackets

32x M8x20 Bolts

32x M8 washers

32x t-nuts

Steps

- On the exterior corner of the 4080 extrusion, slide 3 t-nuts into each top/bottom rail.

- Secure corner plate to rale with accompanying 6 bolt/washer combos.

- Add 2 additional bolt/washer/t-nut combos to the 2 remaining vertical holes. Keep these very loose as we'll slide them into another assembly later.

- Repeat on all corners.

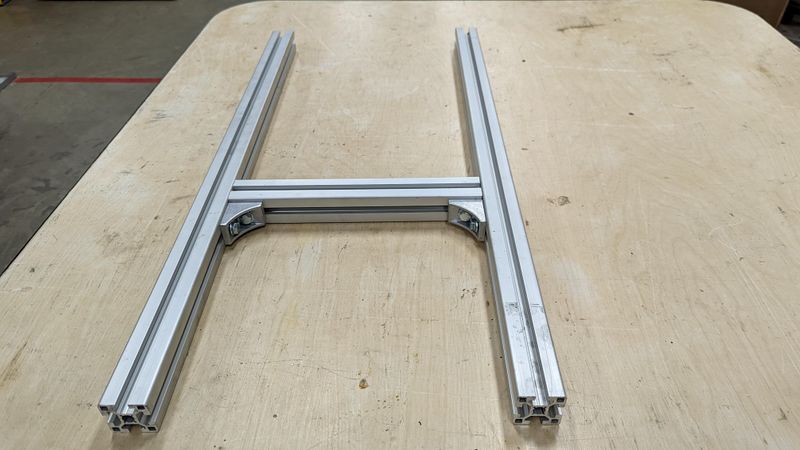

Étape 4 - Table Build - Side Legs 1

Tools

1/2" Socket Wrench

Parts

4x 800mm 4040 Aluminum extrusion

2x 300mm 4040 Aluminum extrusion

4x corner Brackets

8x M8x20 Bolts

8x M8 washers

8x t-nuts

Steps

- Slot 2 t-nuts into one rail of the 300mm extrusion

- Secure corner brackets on the rail, ensuring that the ends are flush with the beam.

- Slide a t-nut into a rail on the 800mm extrusion about 12in from the end.

- Secure one side of the short beam to the long beam.

- Repeat on the other side.

- Repeat steps 1-5 so you have 2 "H" assemblies.

Étape 5 - Table Build - Side Legs 2

Tools

1/2" Socket Wrench

Parts

2 "H" Assemblies from previous step

Top deck Assembly

Steps

- Shift the top deck assembly off your worksurface so that 2 corners are free hanging in space.

- Position an H assembly underneath the corners, aligning the pre-attached t-nuts to the external rail slots. This requires you to adjust the t-nuts so they are perfectly vertical.

- Slide the H assembly up until it is flush with the top deck and holding its weight.

- Once in place, tighten down the bolts

- Repeat on the other side.

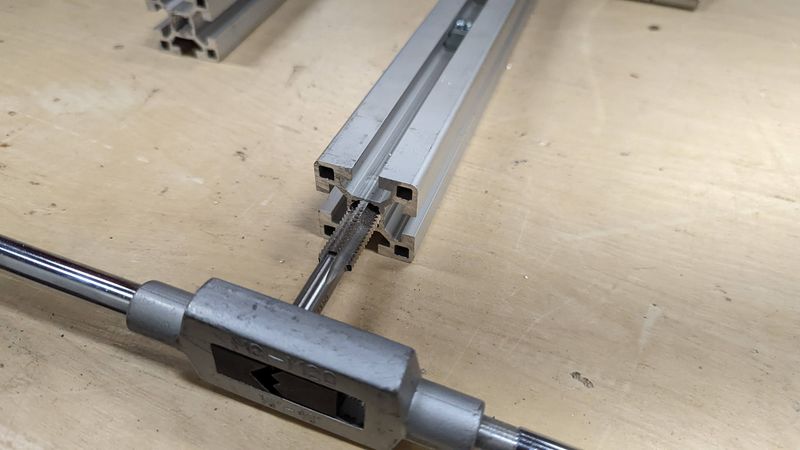

Étape 6 - Table Build - Tapping beams

Tools

1/2" tap

Parts

Table assembly

Steps

- Tap the two central holes on the exterior of the 1000mm 4080 extrusion.

- Repeat on all 4 corners.

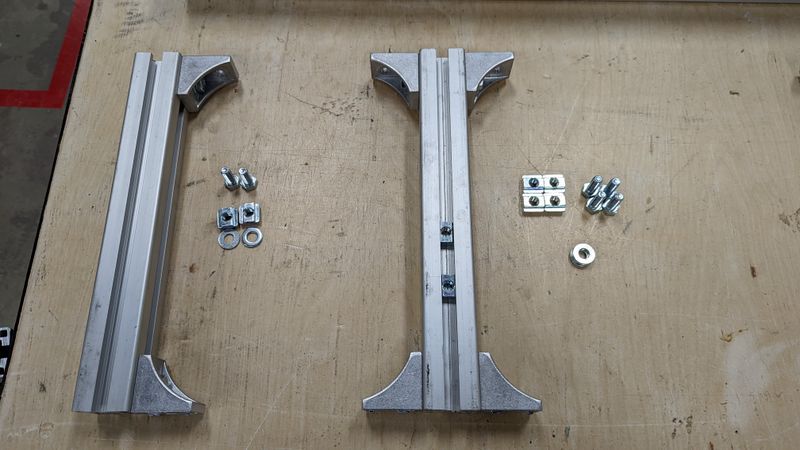

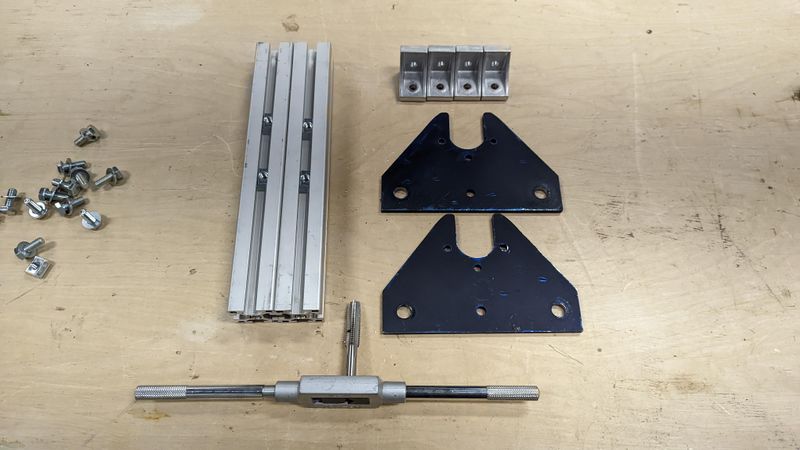

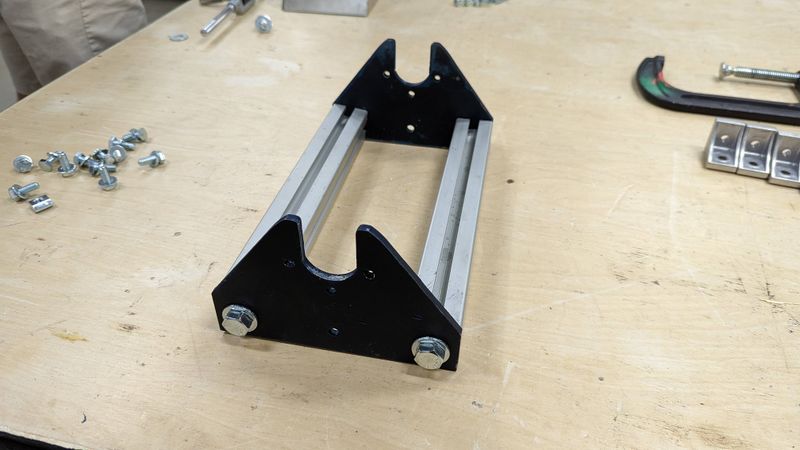

Étape 7 - Barrel Support 1

Tools

1/2" tap

1/2" socket wrench

3/4" socket wrench

Parts

2x 300mm Extrusion

2x Steel barrel brackets

4x corner brackets

4x 1/2"x1" hex bolts

4x 1/2" washers

4x M8x20 Bolts

4x M8 washers

4x t-nuts

Steps

- Tap both end holes in each 300mm beam.

- (check to make sure the 1/2 bolts fit through the large holes on the barrel brackets. If not, use a 1/2" drill bit to open the holes up)

- Slide 2 nuts into each beam. position these rails on the outside/facing away from each other (see image 6 for orientation)

- Secure the barrel brackets to the beams as seen in image 5.

- Secure corner brackets to slotted t-nuts so the open hole is facing down. Keep these loose as there final position will be determined later.

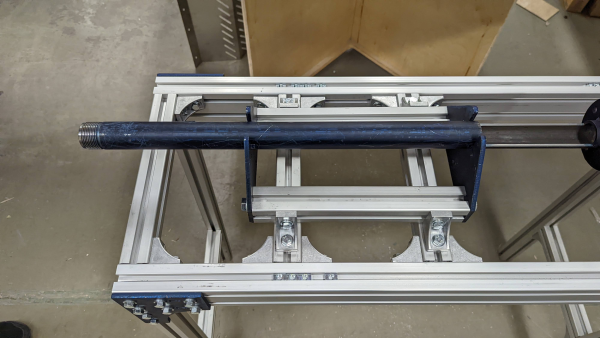

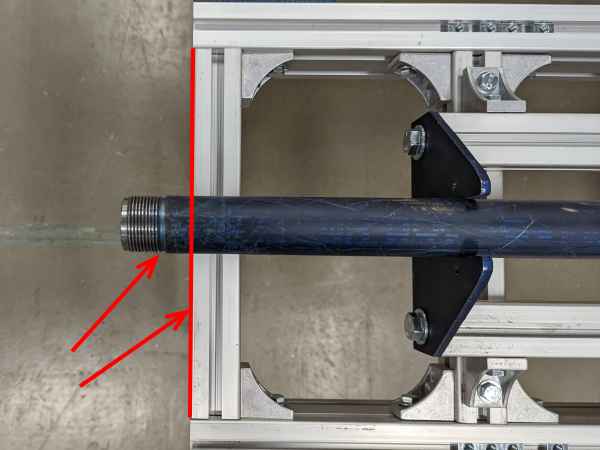

Étape 8 - Barrel Support 2

Tools

1/2" socket wrench

Parts

Barrel Support Assembly

Table

Barrel

4x M8x20 Bolts

4x M8 washers

Steps

- Place the Barrel support assembly on the table so it that it crosses the two "I" assemblies.

- Loosely attach the assembly to the table with bolts/washers.

- Place the barrel into the support structure, aligning the flat notches on the barrel to the bracket.

- Slide the barrel towards the end of the table until the threads CLEAR the table face.

- Leave these connections loose as it will be moved into its final position later.

- Temporarily remove the barrel.

Étape 9 - Barrel/Shaft/Bearings

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português