This tutorial documents the build process for the Precious Plastic Extruder Pro as supplied by Citizen Scientific Workshop out of Idaho, United States.

Difficulté

Moyen

Durée

2 jour(s)

Catégories

Machines & Outils, Recyclage & Upcycling

Coût

3000 USD ($)

Matériaux

Outils

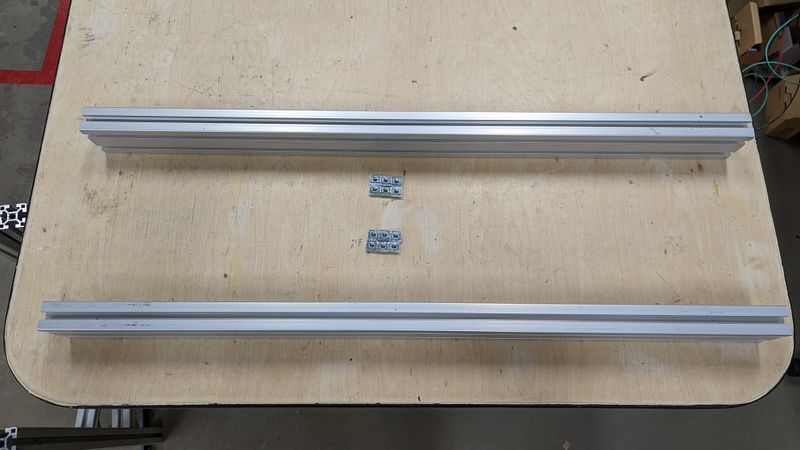

Étape 1 - Table Build-Top deck 1

Tools

1/2" Socket

Parts

2x 1000mm 4080 extrusion

4x 300mm 4040 extrusion

40x t-nuts

22x M8x20 bolts

22x M8 Washers

12x Corner Brackets

Steps

- Slide 6 t nuts into the top side of the 1000mm extrusion. (repeat for other beam)

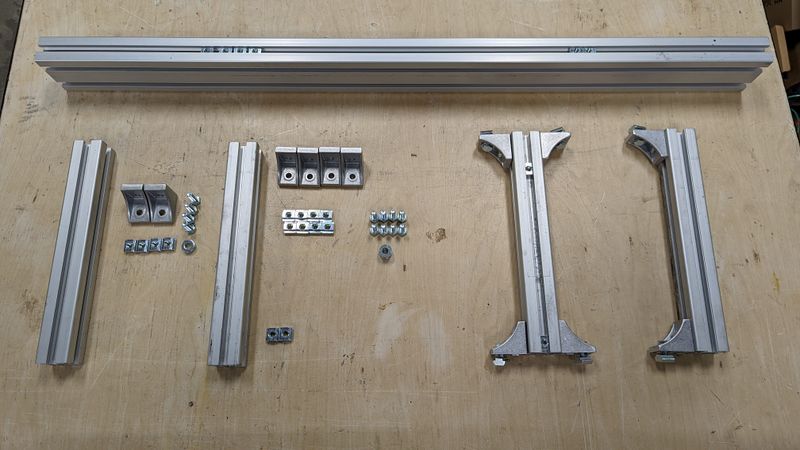

- For the 300mm beams, 2 pairs of 2 will be identical, one "I" shaped, and one "C" shaped.

- For the C-shaped beam, Slide two t-nuts into one rail. Attach the corner brackets at the ends, ensuring the bracket is flush with the beams end. *Always use the side of the bracket with a flat face (non-lipped) first. This ensures you can get a tool onto the 2nd bolt without being blocked.

- For the I-Beams, repeat the same steps for the C-beam, but on both sides.

- Repeat so you have 2 I-beams and 2-C beams.

- *Optional* Add bolts to all remaining bracket holes and loosely attach t-nuts. (as seen in the right two beams in image 3)

Étape 2 - Table Build- Top deck 2

Tools

1/2" Socket Wrench

Parts

Assemblies from previous step

Steps

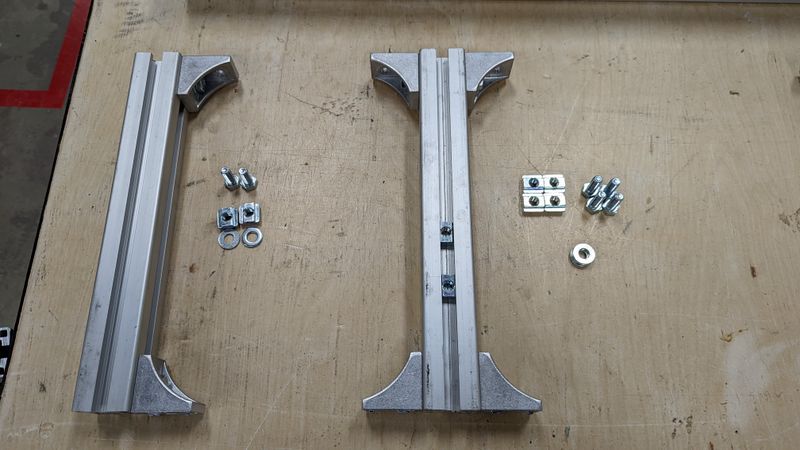

- If you have already attached the bolts/and t-nuts from the optional step - Slide beams into the upper channel (as seen in image 1) Otherwise, thread the nuts into the channel and attach LOOSELY with bolts.

- Repeat for the bottom rail.

- Secure the C beams in place with the socket wrench, but leave the I-beams LOOSE as they will need to be shifted later.

Étape 3 -

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português