Introduction

In this tutorial, I share the journey of how I built the FlyPi biology tool, without any previous electronics experience, so I could feed my insatiable urge to see how things work. Microscopy offers a lens to explore each visual frontier with its wonderful new perspectives and illuminates minuscule life regularly unobserved. This is an amazing experiences for anyone curious of what lies beneath our immediate visual capabilities. One main constraint for curious students, researchers and/or educators to look deeper into the micro world, is access to effective scientific tools. This is likely due to high prices set by development under a patent/scarcity methodology. Building your own FlyPi is a relatively easy and cost effective way to to get around this limiting factor. FlyPi is an all-in-one biology lab with powerful “off-the-shelf” electronic elements (Raspberry Pi & Arduino nano). It's modularity offers a fast, effective and low cost way to have better experimental control by customizing for specific needs and most importantly enables accessibility to research and explore the microscopic world around us. Just putting it together is a great learning experience for everyone not immediately comfortable with electronics. Some People have even begun to join scientific efforts in pursuing solutions to their local problems!

Steps

1- Understanding Modularity: How to decide which build is needed

2- Gathering materials & Creating parts: - Show the options to buy parts from kitspace, but also add links to the original github repository, stating that due to modularity, not all parts are necessary for basic functionality. (on the repository there are more detailed bill of material files)

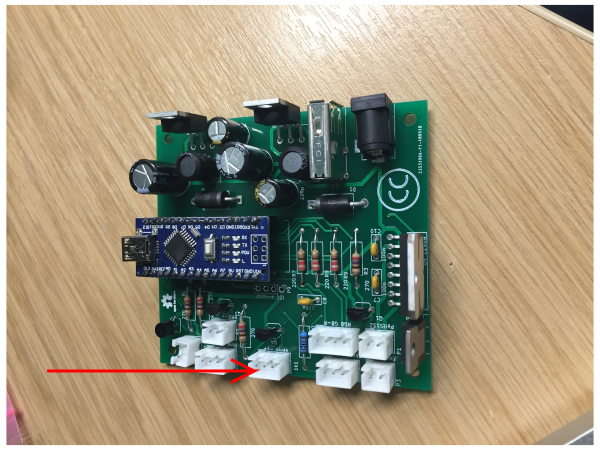

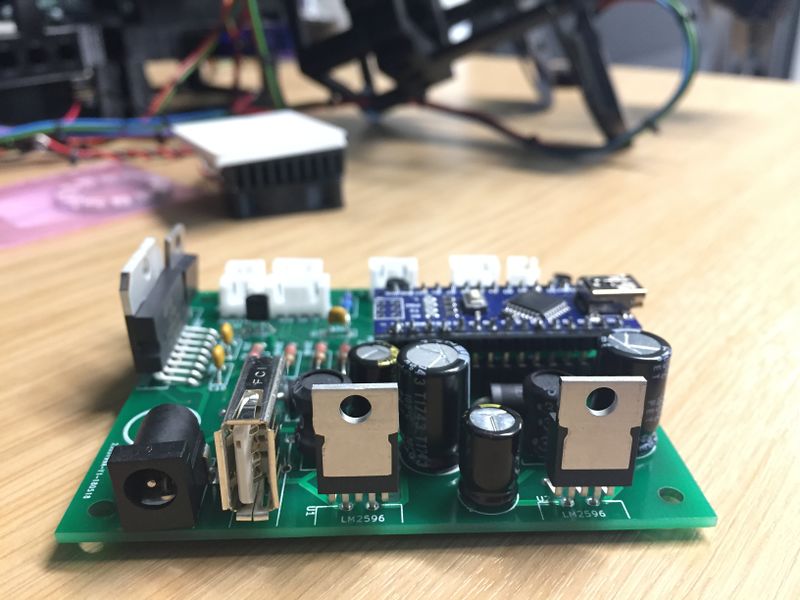

3- Building PCB hardware: Quick overview of the PCB build. Note the space left due to the absence of the servo motor for the (x,y) axis movement.

4- Combining 3D printed body: Modular flexibility in use.

5- Software Installation: How to install interface and useful imagej FIJI software on SD card

6- Launching the FlyPi: Putting it all together to start collecting image data!

Matériaux

Monitor

Computer mouse - USB

Keyboard - USB

3D print files (.stl) : Under 'Files' tab above

Custom PCB (Principle Component Board parts can be found on: https://kitspace.org/boards/github.com/prometheus-science/flypi/ )

Outils

Soldering Iron, Solder

Computer with:

- ability to connect SD card

- internet Connection

3D printer

Étape 1 - Understanding Modularity

1- Modularity: Broadly speaking, is the degree to which a system's components may be separated and recombined, often with the benefit of flexibility and variety in use. Examples of modularity are things like cars, computers, solar panels, lego blocks and biological cells. Principles behind modularity posit that systems should be built from cohesive loosely coupled components, sometimes referred to as modules, with a defined function or purpose.

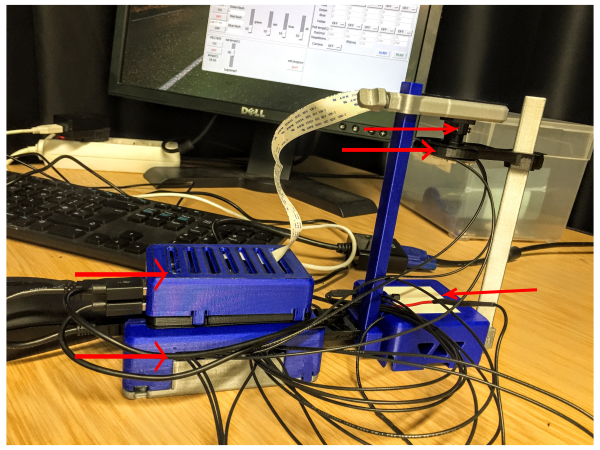

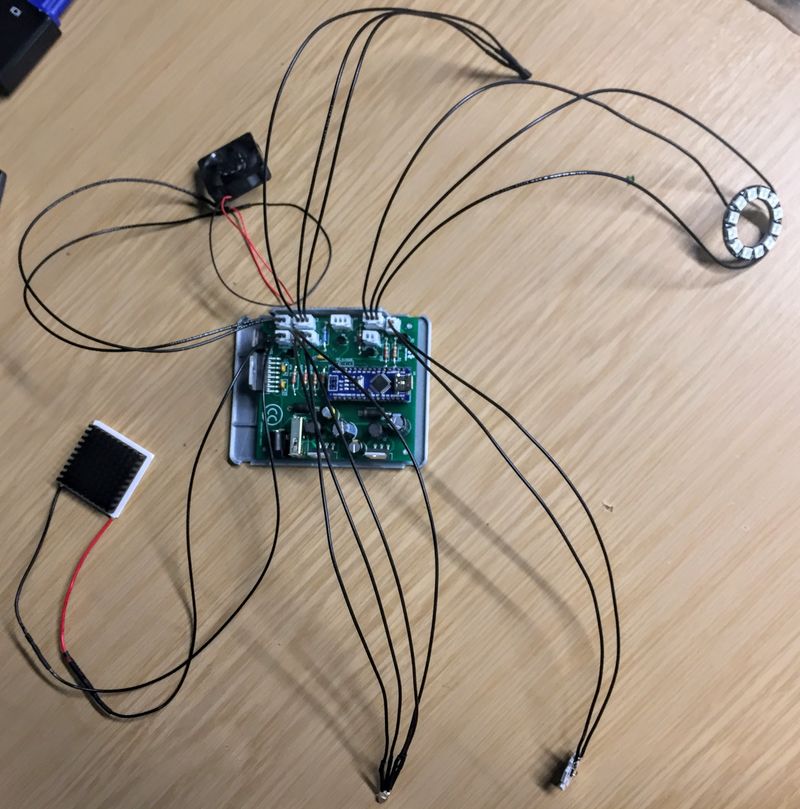

The FlyPi is designed in a modular fashion to optimize diverse capabilities. The base pieces are the raspberry pi, raspberry pi cam, the PCB with the Arduino and the 3D printed housing. The raspberry pi acts as the computer for the camera and the PCB/Arduino controls the mechanical functions of the modules. The modules in the PCB are Peltier module (temperature controlled plate), the multicolour LED ring, the UV light, the fans for the UV light and Peltier, the thermostat and the indication LED for the Peltier. It's important to point out that all modules do not have to be added which can save time and money. If desired, modules can be added at any point.

To begin, I determined which modules I wanted to have. I decided to keep all but the servo motor that provided some (x,y) axis movement for the slide. My samples were large enough that manual movement would be sufficient. I also knew I wanted to customize the design for an (x,y,z) axis movement to a hydraulic syringe that could be manually manipulated(that's another tutorial).

Étape 2 - Gathering Materials & Creating Parts

2- Gathering materials & Creating Parts: Not all parts are necessary to order for basic functionality. The repository has a detailed bill of materials that can be tailored to specific needs.

- Electronic parts can be ordered from this kitspace page (lists have been conveniently compiled in various online market shopping carts):

https://kitspace.org/boards/github.com/prometheus-science/flypi/

- 3D print files can be found in the files tab above. I started printing at the local fablab (fabrication laboratory) after ordering the parts I needed to build the microscope. This way I would have the body ready when the electronics arrived.

Étape 4 - Adding Modules

4- Software Installation: How to install useful software on SD card

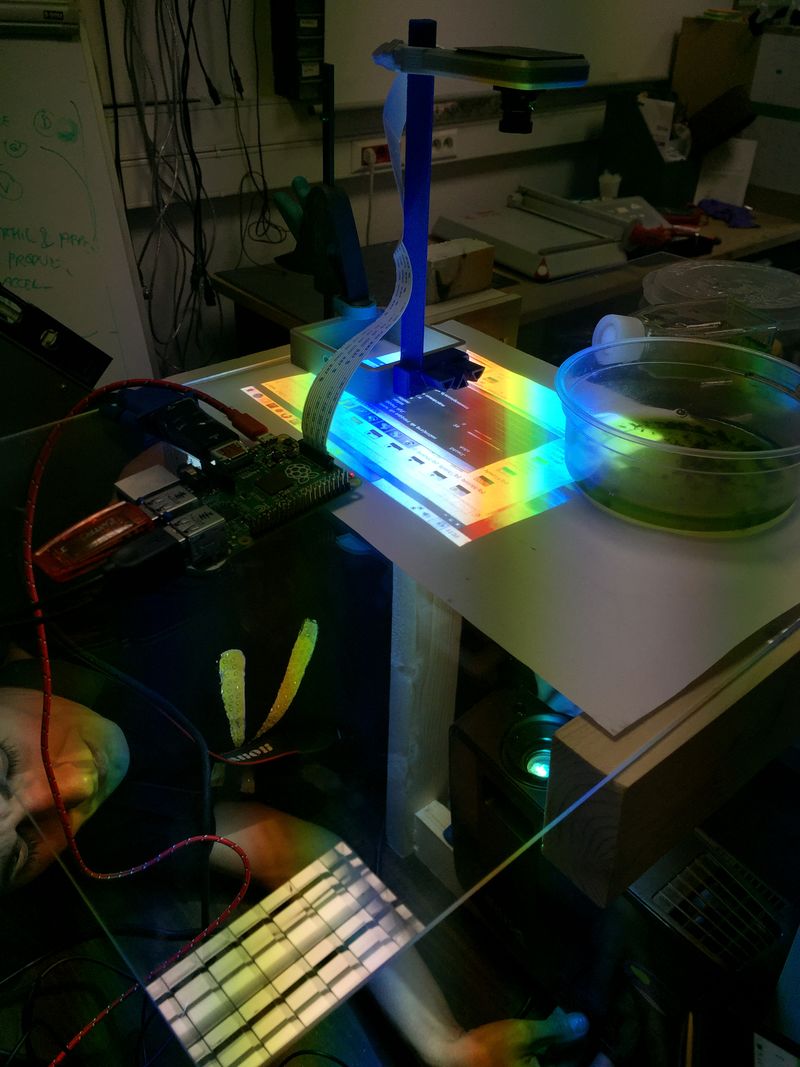

Étape 5 - Launching the FlyPi

5- Launching FlyPi program: Putting it all together to start collecting image data!

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português