| Ligne 146 : | Ligne 146 : | ||

|Step_Picture_01=PP_Sheetpress_PXL_20220114_190641454.jpg | |Step_Picture_01=PP_Sheetpress_PXL_20220114_190641454.jpg | ||

|Step_Picture_02=PP_Sheetpress_PXL_20220114_192000012.jpg | |Step_Picture_02=PP_Sheetpress_PXL_20220114_192000012.jpg | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Leg install</translate> | ||

| + | |Step_Content=<translate>==== Tools ==== | ||

| + | 1/2" socket | ||

| + | |||

| + | At least 2, better with 3, people | ||

| + | |||

| + | Clamps | ||

| + | |||

| + | ==== Parts ==== | ||

| + | Top plate assembly | ||

| + | |||

| + | 4x legs | ||

| + | |||

| + | 4x corner plates (12-hole, shaped like a 7) | ||

| + | |||

| + | 48x m8x20 bolts | ||

| + | |||

| + | 48x m8 t nuts | ||

| + | |||

| + | 48x m8 washers | ||

| + | |||

| + | ==== Steps ==== | ||

| + | |||

| + | # Slide 6 t-nuts (3 in each channel) in the corner of the top plate assembly. Align the holes with the corner plate pattern, preparing for a blind fit. | ||

| + | # Attach the plate with bolts/washers loosely. *there are a few ways you could do this next section, but we found this method to be effective with only 2 people, but we recommend using more! * | ||

| + | # Place 6 more bolts/washers in the open section of the support plate, and loosely screw on t-nuts for only a thread or two. You want these to be flexible. | ||

| + | # Person A: Lift the leg directly above the plate and do your best to "Float" the leg so it is weightless for person B | ||

| + | # Person B: thread the channels on the leg over the pre-positioned t-nuts, 2 at at time, until the leg drops down into position (image 3) | ||

| + | # Repeat for all 4 legs. At this point the top assembly should still be supported by the table below. Get your third person ready. | ||

| + | # Have two people lift the top assembly so it slides up the rails until it is flush with the top of the leg extrusions. | ||

| + | # Have your third person tighten down at least 2 bolts on all 4 corners, transferring the weight to the legs. | ||

| + | # Use clamps to secure all beams into a flush position, then tighten down all bolts.</translate> | ||

| + | |Step_Picture_00=PP_Sheetpress_PXL_20220114_195752785.jpg | ||

| + | |Step_Picture_01=PP_Sheetpress_PXL_20220114_201719067.jpg | ||

| + | |Step_Picture_02=PP_Sheetpress_PXL_20220114_202523364.jpg | ||

| + | |Step_Picture_03=PP_Sheetpress_PXL_20220114_204124320.jpg | ||

}} | }} | ||

{{Notes | {{Notes | ||

Version du 15 janvier 2022 à 00:42

Matériaux

Outils

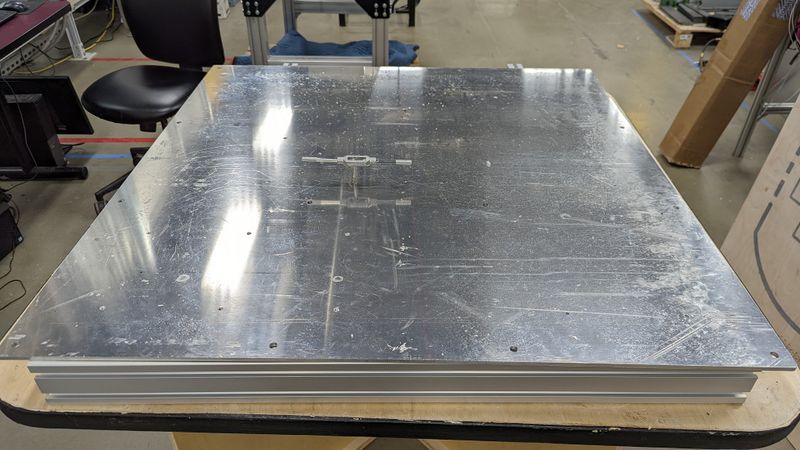

Étape 1 - Top and Bottom Plates (grid structure 1)

*The following 2 steps will be used to make 2 identical plate assemblies. The parts listed are for 1 assembly (so double everything if you're making two plates at a time)

Tools

1/4"-20 tap + tap handle

countersink (or anything over 1/4" bit) for hole cleanup

1/2" Socket

Parts

1 meter aluminum sheet

2x 1000mm 4080 extrusion

4x 920mm 4080 extrusion

4x 286mm 4080 extrusion

2x266mm 4080 extrusion

156 T-nuts (16*9) + 12)

156 M8x16mm Bolts

156 M8 washers

Steps

- Tap the 36 pre-drilled 13/64" holes with the 1/4"-20 tap.

- use the countersink bit to clean up any debris.

- Layout the large extrusion (image 2) so that the 1m sides are parallel, and the 960mm beams are evenly distributed at 90 degrees to the 1m beams.

- Insert 12 t-nuts (6 in each row) into each extrusion face that faces the inside of the plate. (image 2). 8 faces total(4 from exterior beams, and 4 from each side of the two interior beams. 96 nuts total

- Position the two 266mm beams in the center row, splitting it into 3 equal sections.

- Position the four 286mm beams in the top and bottom rows, matching the position of the 266 beams.

- For each 80mm face of these interior beams, place 4 t nuts (2 in each slot). Be sure to place these on both faces. 48 nuts total.

Attaching the exterior beams to the plate

- On the bottom 40mm face, slide 4 t nuts into each 1000mm beam. (image 4)

- Match these T nuts with the holes in the plate as this will be a "blind" install. (image 5)

- slide the plate off your work area so you can access the holes from below.

- Place the extrusion directly on top of the plate ensuring not to shift it off its alignment.

- Using the M8 bolts, secure the beam to the plate.

- Repeat this process until you have attached both 1000mm beams and 960mm beams. (12 bolts total)

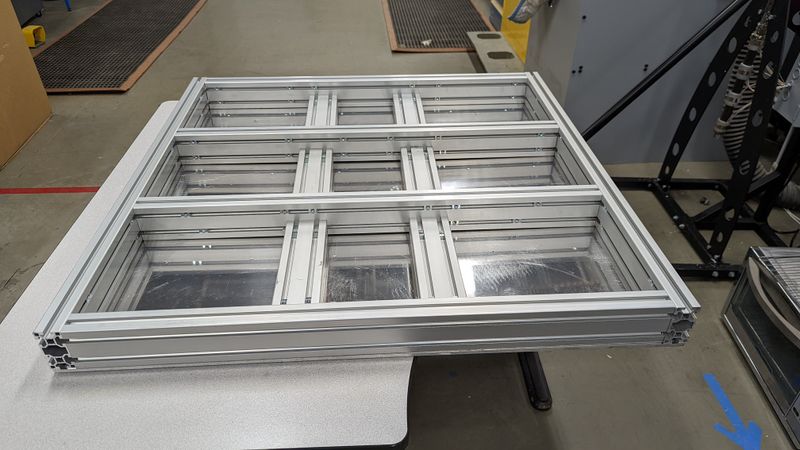

Étape 2 - Top and Bottom Plates (grid structure 2)

Tools

same as above

Parts

36 corner brackets

Steps

- Prepare your parts. Each "cell" will require 4 brackets, 16 M8Bolts, and 16 washers

- Starting with the 4 corners of the entire assembly, attach the corner brackets and tighten the bolts only to finger-tight.

- Next attach the 920 beam ends to the outer perimeter.

- Next, attach the inner beams in place. Ensure that all beams are equally spaced. (remember that the 2 interior beams are shorter though)

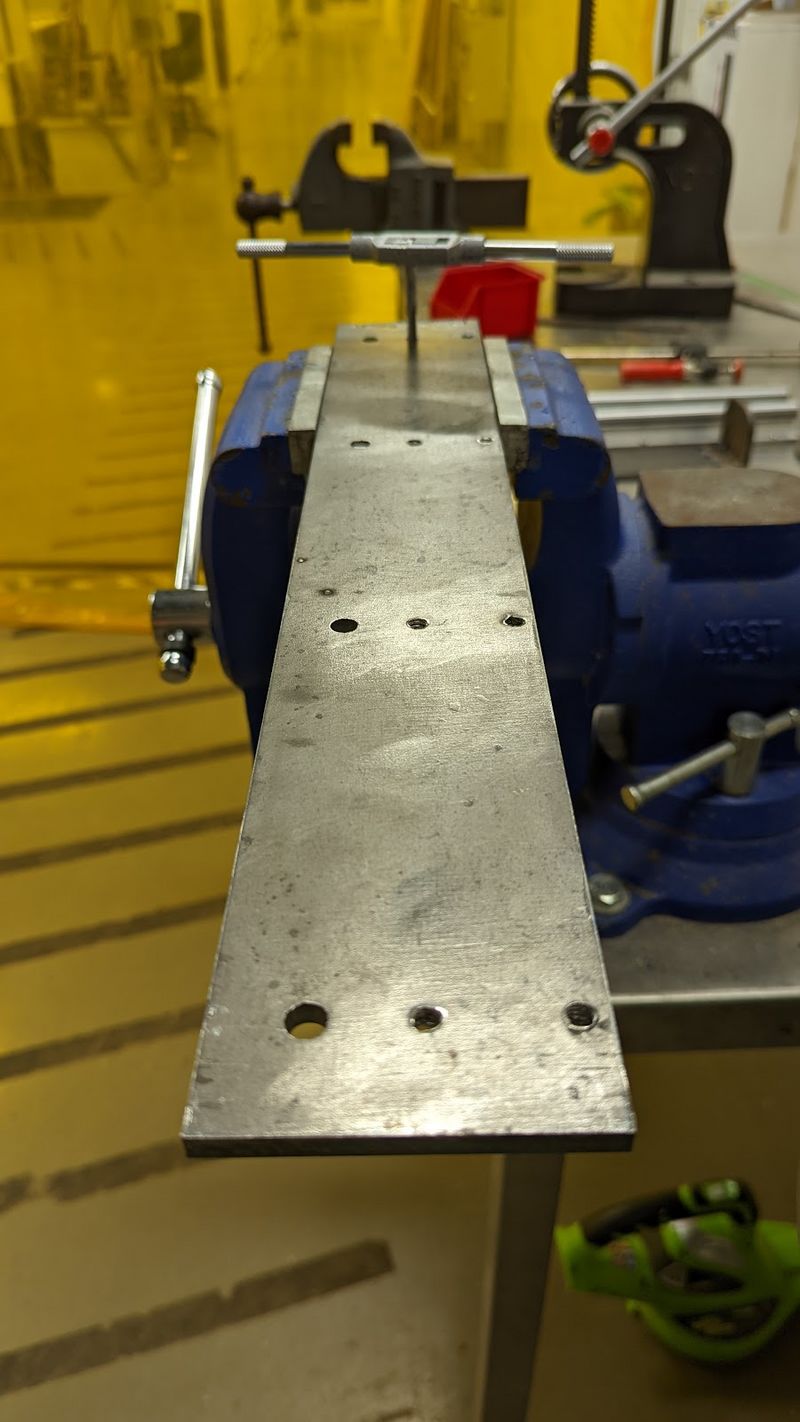

Étape 3 - Leg Linear Rail Prep

Tools

(welder?)

Drill press

Grinder

Vice

1/4-20 Tap

Parts

4x Linear rail plates (w/ 90degree stopper plate)

4x Linear rail posts

16x 1/4"-20 x 3/8" bolts

Steps

- (if not already done) weld the small stopper plate to the end of the long linear rail leg plate. Be sure you have two mirrored sets and not four identical pieces. (see image 5)

- Grind down the welds (or avoid welding where the linear slide will attach.) This is a very snug fit and you may have to make some room for proper alignment

- You can also drill out the slide rail mounting holes (aluminum) to give yourself a little more room for a proper fit.

- Image 4 shows the holes not in perfect alignment, so you may have to grind the linear rail bar down until the wholes are perfectly aligned.

- Tap all 8 small holes to 1/4"-20

- Align and install the linear rail to the plate. Add the bearing carriages. (repeat for all 4 plates)

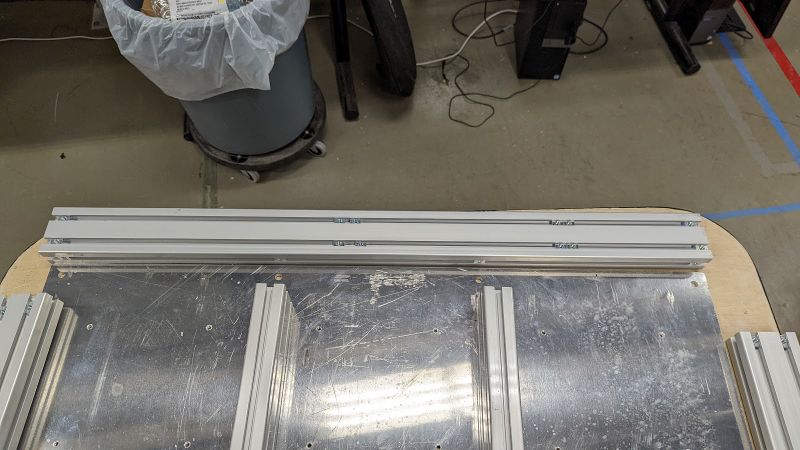

Étape 4 - Leg linear Rail install

Tools

1/2" socket

Parts

16x m8x20 bolts

16x m8 washers

16x m8 t-nuts

4x 8080 extrusion

Steps

- Slide 4 t nuts into the 8080 extrusion rail.

- Position one linear slide just next to the rail so you can align the t-nuts to the holes as this will again be a "blind" install.

- Attach the linear slide so it is flush with the end of the extrusion.

- repeat for all 4 rails so you have 2 mirrored pairs.

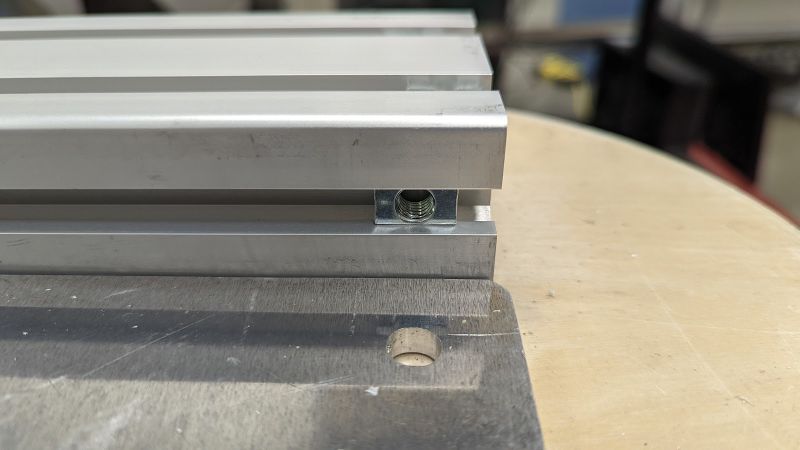

Étape 5 - Leg install

Tools

1/2" socket

At least 2, better with 3, people

Clamps

Parts

Top plate assembly

4x legs

4x corner plates (12-hole, shaped like a 7)

48x m8x20 bolts

48x m8 t nuts

48x m8 washers

Steps

- Slide 6 t-nuts (3 in each channel) in the corner of the top plate assembly. Align the holes with the corner plate pattern, preparing for a blind fit.

- Attach the plate with bolts/washers loosely. *there are a few ways you could do this next section, but we found this method to be effective with only 2 people, but we recommend using more! *

- Place 6 more bolts/washers in the open section of the support plate, and loosely screw on t-nuts for only a thread or two. You want these to be flexible.

- Person A: Lift the leg directly above the plate and do your best to "Float" the leg so it is weightless for person B

- Person B: thread the channels on the leg over the pre-positioned t-nuts, 2 at at time, until the leg drops down into position (image 3)

- Repeat for all 4 legs. At this point the top assembly should still be supported by the table below. Get your third person ready.

- Have two people lift the top assembly so it slides up the rails until it is flush with the top of the leg extrusions.

- Have your third person tighten down at least 2 bolts on all 4 corners, transferring the weight to the legs.

- Use clamps to secure all beams into a flush position, then tighten down all bolts.

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português