| Ligne 66 : | Ligne 66 : | ||

|Step_Content=<translate>After the 3D printing is complete, take the bottom part and put the aluminium bar inside the concave. Then place the top part over the aluminium bar. Turn the spaceship around and screw the 4 screws inside the body in order to fix the pieces together. | |Step_Content=<translate>After the 3D printing is complete, take the bottom part and put the aluminium bar inside the concave. Then place the top part over the aluminium bar. Turn the spaceship around and screw the 4 screws inside the body in order to fix the pieces together. | ||

| − | On the top of the spaceship you can use a 2-by-4 Lego plate to fix the lego figure by placing the plate inside the . Then screw the | + | On the top of the spaceship you can use a 2-by-4 Lego plate to fix the lego figure by placing the plate inside the cockpit. Then screw the cockpit to fix it.</translate> |

|Step_Picture_00=Spaceship_Assembly.jpeg | |Step_Picture_00=Spaceship_Assembly.jpeg | ||

|Step_Picture_01=Spaceship_tube.jpeg | |Step_Picture_01=Spaceship_tube.jpeg | ||

Version du 22 janvier 2020 à 18:48

Introduction

Material

1 x aluminium tube 20 mm x 2 mm x 1 meter (or 3/4 inch) the design makes it possible to use either one

1 x universal cord

1 x Lego mini-figure

4 x screws (standard wood screws)

Machines and tools:

3D printer to print the spaceship

Metal saw to cut the aluminium tube

Metal Chamfer Tool to sand edges of cut aluminum

Matériaux

Outils

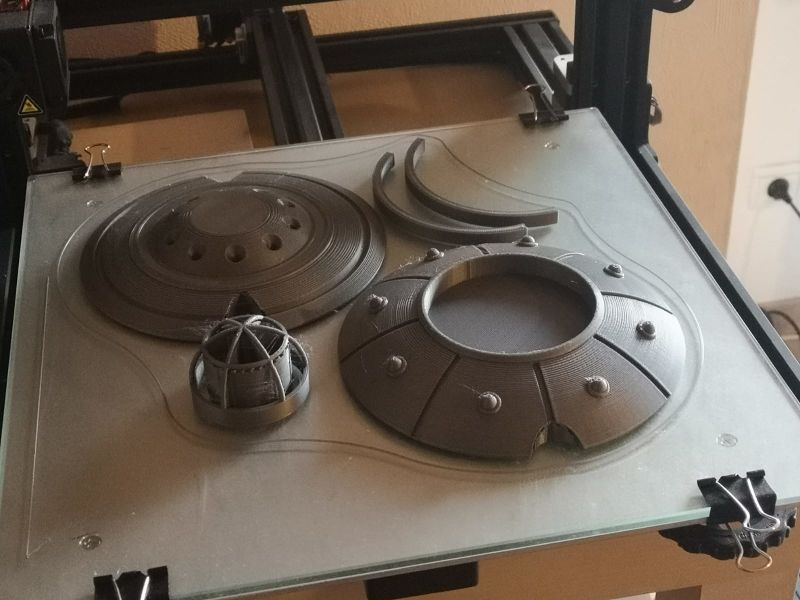

Étape 1 - Printing the spaceship

3D-Print the several parts of the spaceship. This is going to take several hours per part. If your 3D printer is not big enough to place all the part at once, you can do it in two prints.

- Top part: 10h

- Bottom part: 10h

- Dome part: 1h

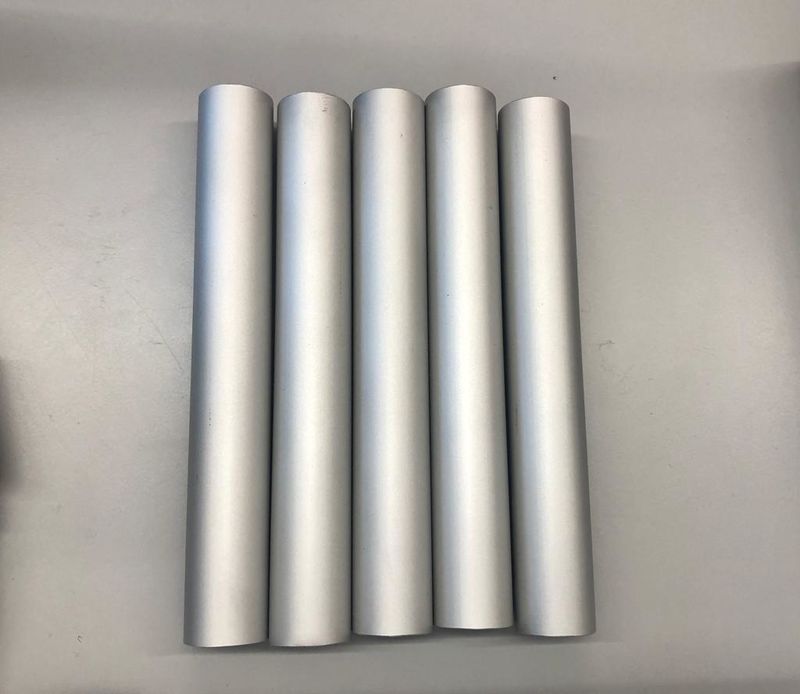

Étape 2 - Cut the aluminum

While waiting for the spaceship parts to be printed, cut the aluminum bar into 5 parts (14 cm each).

The first part will be used for the spaceship. The other parts will be used for the handles.

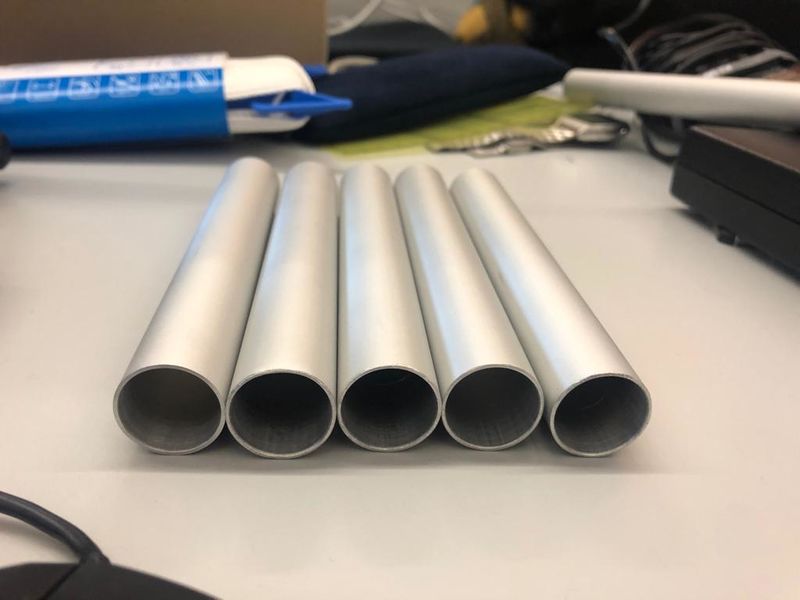

Étape 3 - Prepare the handles

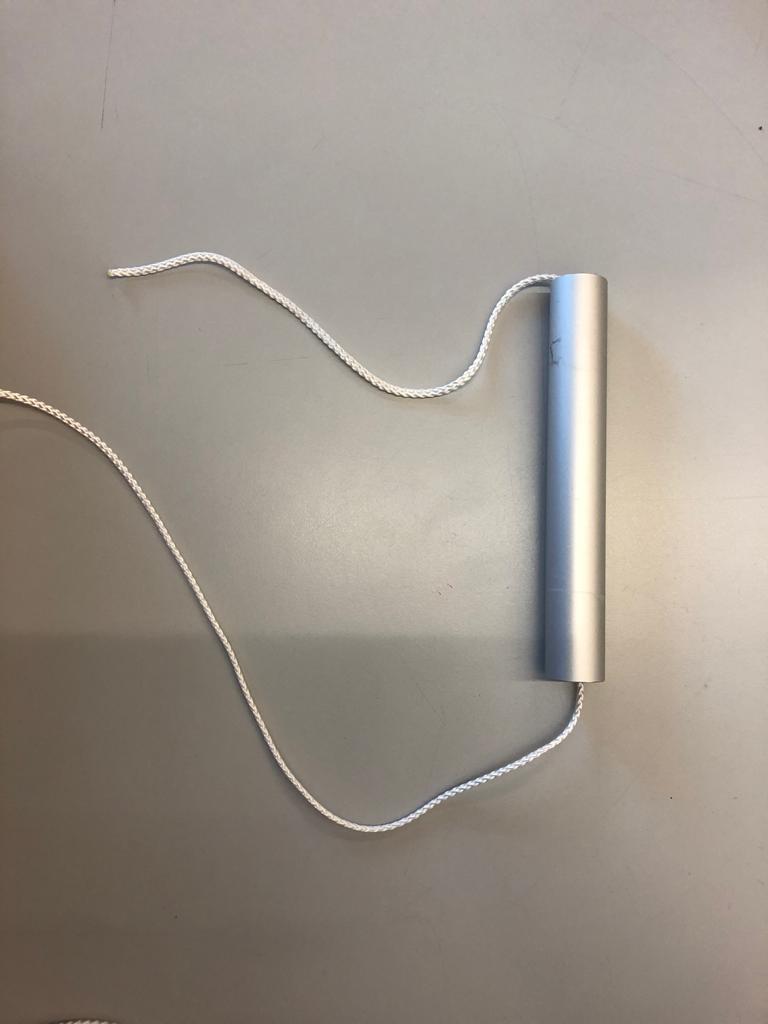

Take two tubes and cut a piece of the cord (approx 2-3 meters) to create the 2 handles. Chamfer (sanding) the edges of the cut aluminum tubes to avoid hand injuries (using the metal chamfer tool). It is preferable to use the semi-circle profile chamfer to sand both the outside and inside of the tube. Then do the same thing with sandpaper in order to have a smother finishing.

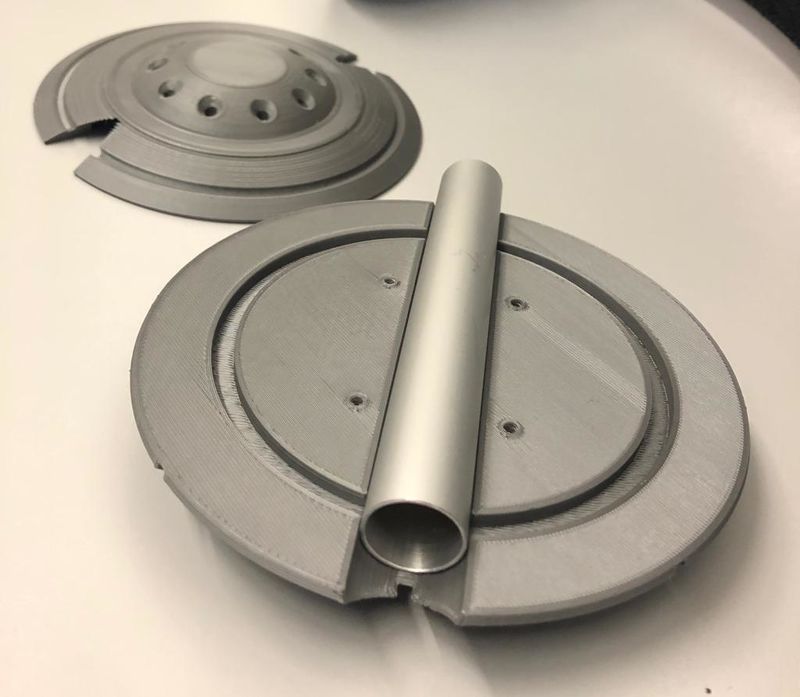

Étape 4 - Assemble the spaceship

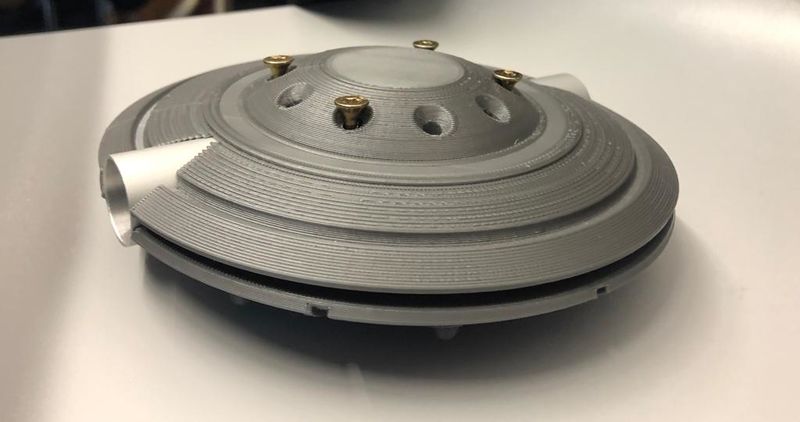

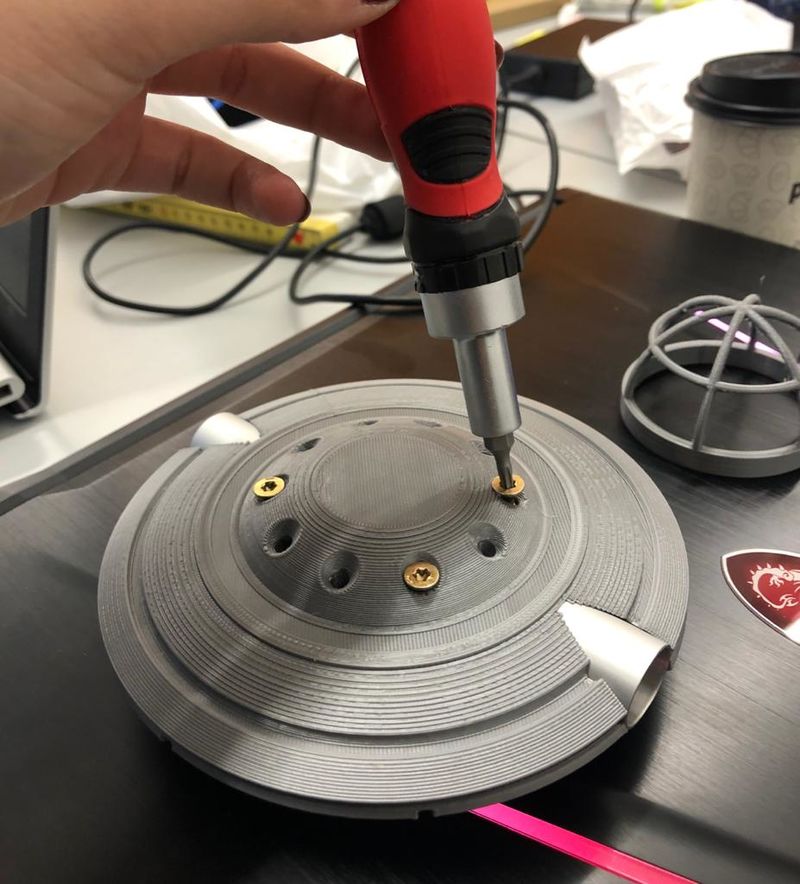

After the 3D printing is complete, take the bottom part and put the aluminium bar inside the concave. Then place the top part over the aluminium bar. Turn the spaceship around and screw the 4 screws inside the body in order to fix the pieces together.

On the top of the spaceship you can use a 2-by-4 Lego plate to fix the lego figure by placing the plate inside the cockpit. Then screw the cockpit to fix it.

Étape 5 - Finishing up

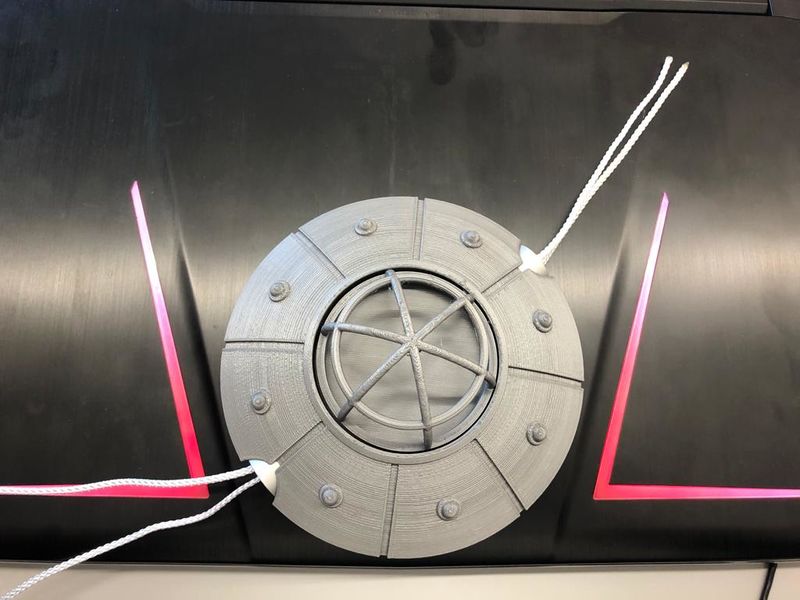

Burn the ends of the cords off and pass them through the tubes and make some rigid knots for the handles. Then pass the two cords through the spaceship and create the same knots with the two other tubes for the handles.

Étape 6 - Play!

Two people take the handles and start making the spaceship move from one person to the other by opening and closing the arms at the right time as shown in the video. Make sure the cords are crossed so the spaceship can move properly.

Étape 7 - Options

You can add some landing gears if you feel like your spaceship needs to be presented nicely before and after playing with it. You can screw it on to the ship or just use it as a base.

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português