(Imported page from en.wikifab.org) |

(update property name) |

||

| (5 révisions intermédiaires par 3 utilisateurs non affichées) | |||

| Ligne 1 : | Ligne 1 : | ||

{{Tuto Details | {{Tuto Details | ||

| − | |SourceLanguage= | + | |SourceLanguage=none |

|Language=en | |Language=en | ||

|IsTranslation=0 | |IsTranslation=0 | ||

|Type=Creation | |Type=Creation | ||

|Area=Robotics, Energy, Science and Biology | |Area=Robotics, Energy, Science and Biology | ||

| − | |Description=Extrusion is a continuous process where plastic flakes are inserted in the hopper and extruded into a line of plastic. These lines can be used to make new raw material (3d printing filament), granulate, spinned around a mold or up to you to find new creative ways. | + | |Description=<translate><!--T:1--> Extrusion is a continuous process where plastic flakes are inserted in the hopper and extruded into a line of plastic. These lines can be used to make new raw material (3d printing filament), granulate, spinned around a mold or up to you to find new creative ways.</translate> |

|Difficulty=Hard | |Difficulty=Hard | ||

|Cost=192 | |Cost=192 | ||

| Ligne 15 : | Ligne 15 : | ||

}} | }} | ||

{{Introduction | {{Introduction | ||

| − | |Introduction=The extrusion machine has quite a specific output, a line. This is well suited to make new granulate and 3D printer filament. However use your creativity and you will find other applications for it as well. Change the nozzle for different shapes and sizes, turn it around a mold to make lamps or a handle for a knife. | + | |Introduction=<translate><!--T:2--> |

| + | The extrusion machine has quite a specific output, a line. This is well suited to make new granulate and 3D printer filament. However use your creativity and you will find other applications for it as well. Change the nozzle for different shapes and sizes, turn it around a mold to make lamps or a handle for a knife. | ||

| − | The extrusion machine consists in 6 different elements: the hopper, the barrel, the nozzle, the barrel holder, the framework and the electronics. | + | <!--T:3--> |

| + | The extrusion machine consists in 6 different elements: the hopper, the barrel, the nozzle, the barrel holder, the framework and the electronics.</translate> | ||

}} | }} | ||

{{Materials | {{Materials | ||

| − | |Material=* Metal sheet plates | + | |Material=<translate><!--T:4--> |

| − | * Metal tubes | + | * Metal sheet plates |

| + | * Metal tubes</translate> | ||

|Tools=* Angle grinder | |Tools=* Angle grinder | ||

* Protective glasses | * Protective glasses | ||

| Ligne 33 : | Ligne 36 : | ||

{{Separator}} | {{Separator}} | ||

{{Tuto Step | {{Tuto Step | ||

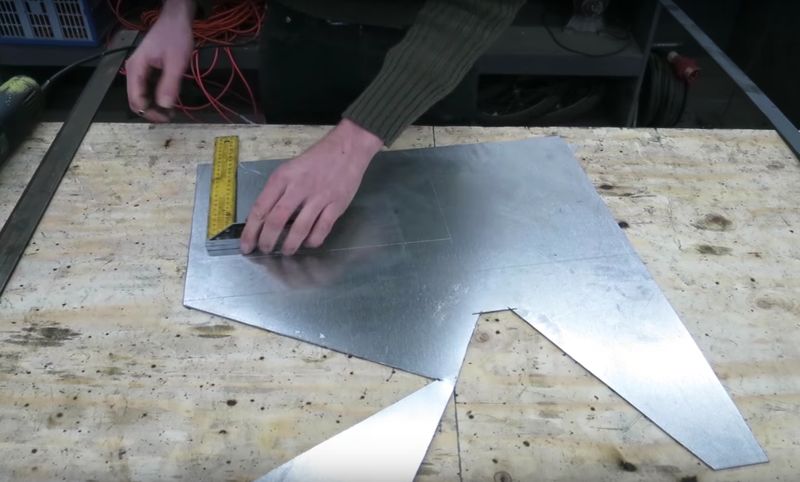

| − | |Step_Title=Hopper: cutting metal plates | + | |Step_Title=<translate><!--T:5--> Hopper: cutting metal plates</translate> |

| − | |Step_Content=Get the metal sheet plates. Take measurements following the blue prints and cut the sheets with a grinding machine and sand metal edges. | + | |Step_Content=<translate><!--T:6--> Get the metal sheet plates. Take measurements following the blue prints and cut the sheets with a grinding machine and sand metal edges.</translate> |

|Step_Picture_00=PPla 1 Hooper 01a.jpg | |Step_Picture_00=PPla 1 Hooper 01a.jpg | ||

|Step_Picture_01=PPla 1 Hooper 01b.jpg | |Step_Picture_01=PPla 1 Hooper 01b.jpg | ||

| Ligne 42 : | Ligne 45 : | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

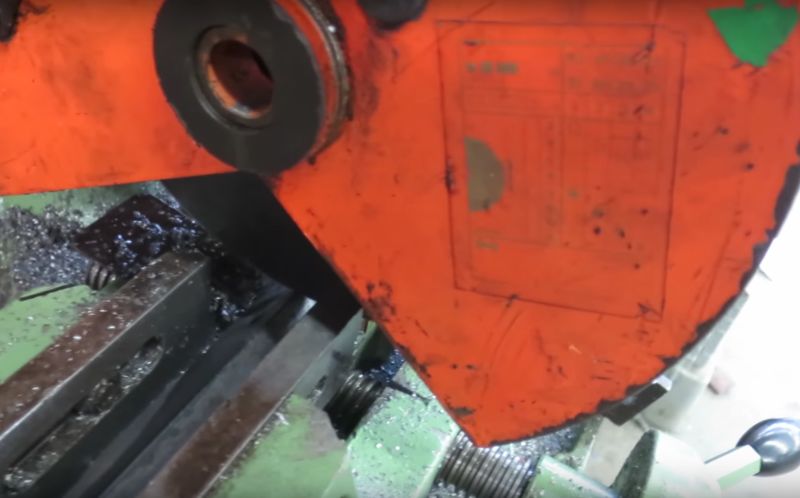

| − | |Step_Title=Hopper: drilling metal plates | + | |Step_Title=<translate><!--T:7--> Hopper: drilling metal plates</translate> |

| − | |Step_Content=Prick the plate with a hammer and drill the metal plates on the milling machine | + | |Step_Content=<translate><!--T:8--> Prick the plate with a hammer and drill the metal plates on the milling machine</translate> |

|Step_Picture_00=PPla 1 Hooper 02a.jpg | |Step_Picture_00=PPla 1 Hooper 02a.jpg | ||

|Step_Picture_01=PPla 1 Hooper 02b.jpg | |Step_Picture_01=PPla 1 Hooper 02b.jpg | ||

| Ligne 49 : | Ligne 52 : | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

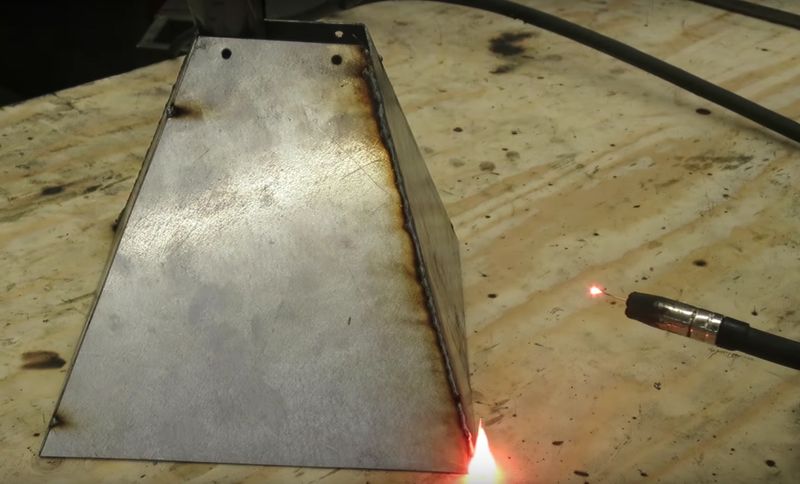

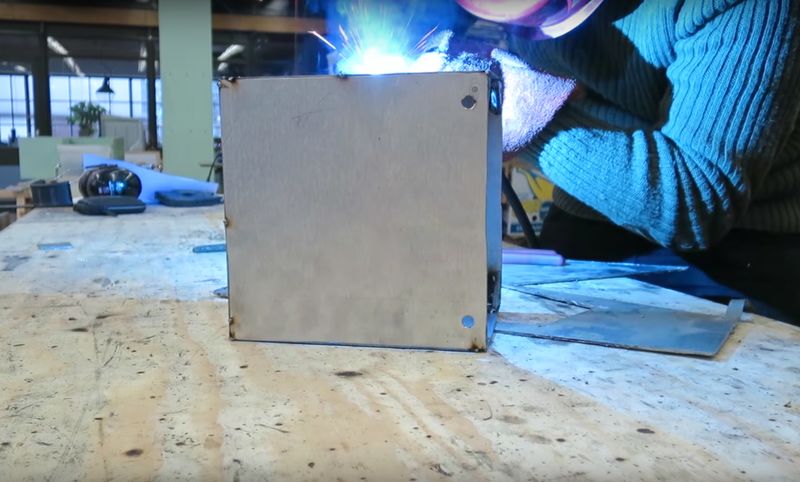

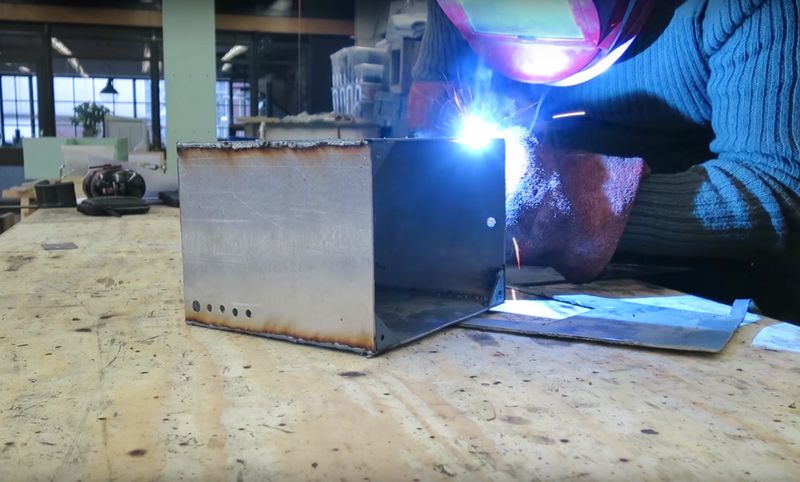

| − | |Step_Title=Hopper: welding metal plates | + | |Step_Title=<translate><!--T:9--> Hopper: welding metal plates</translate> |

| − | |Step_Content=Make a pyramid with the plates and weld them together | + | |Step_Content=<translate><!--T:10--> Make a pyramid with the plates and weld them together</translate> |

|Step_Picture_00=PPla 1 Hooper 03a.jpg | |Step_Picture_00=PPla 1 Hooper 03a.jpg | ||

|Step_Picture_01=PPla 1 Hooper 03b.jpg | |Step_Picture_01=PPla 1 Hooper 03b.jpg | ||

| Ligne 59 : | Ligne 62 : | ||

}} | }} | ||

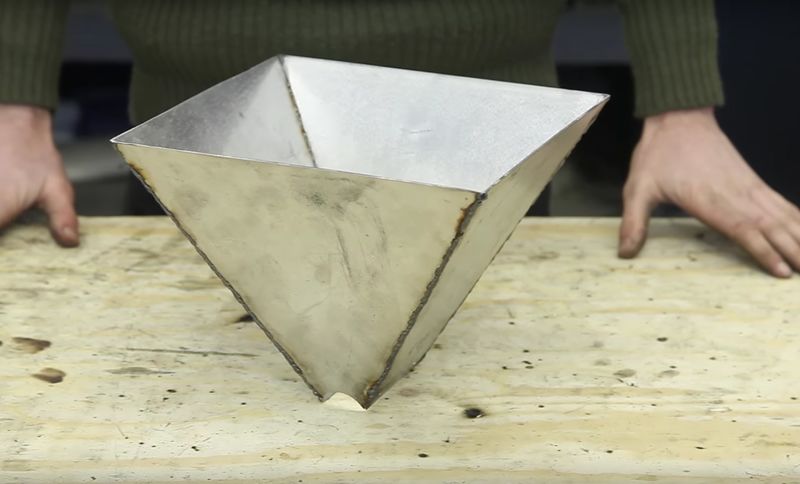

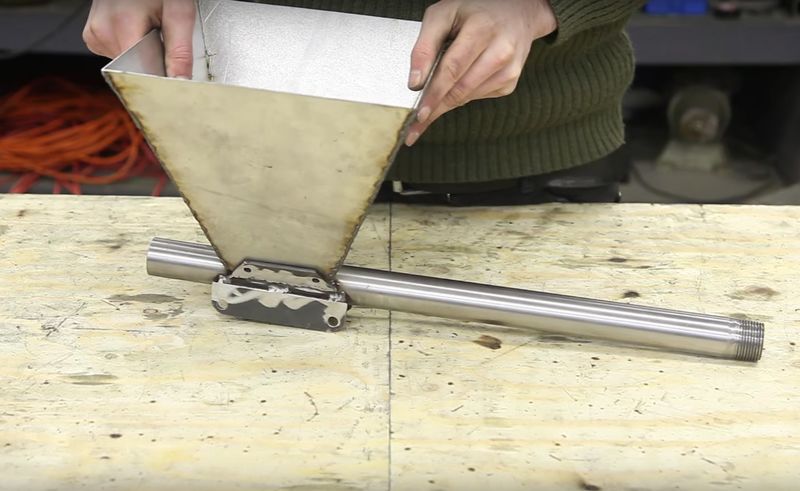

{{Tuto Step | {{Tuto Step | ||

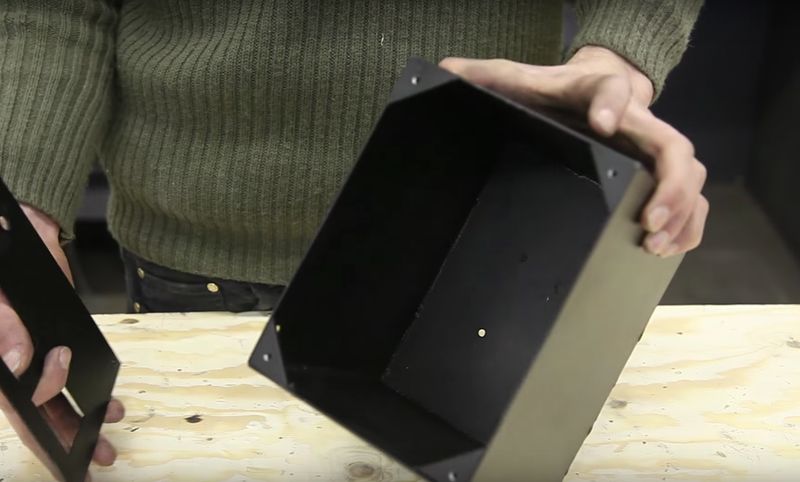

| − | |Step_Title=Hopper finishes | + | |Step_Title=<translate><!--T:11--> Hopper finishes</translate> |

|Step_Picture_00=PPla 1 Hooper 04a.jpg | |Step_Picture_00=PPla 1 Hooper 04a.jpg | ||

|Step_Picture_01=PPla 1 Hooper 04b.jpg | |Step_Picture_01=PPla 1 Hooper 04b.jpg | ||

}} | }} | ||

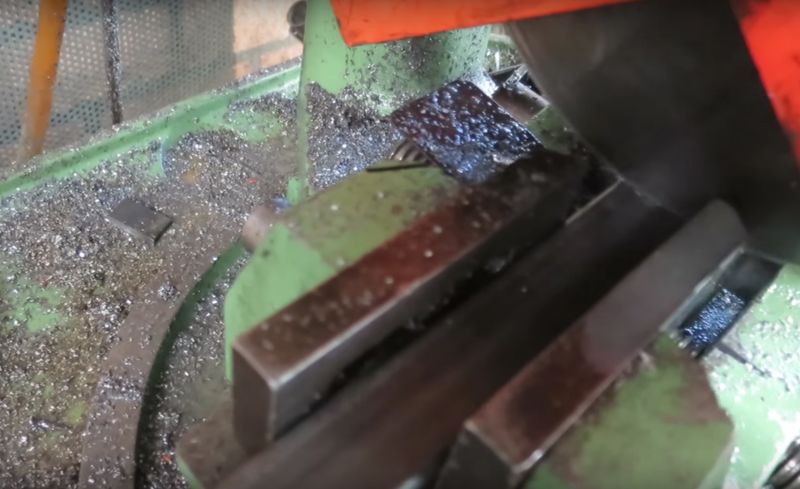

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=Barrel | + | |Step_Title=<translate><!--T:12--> Barrel</translate> |

|Step_Picture_00=PPla 1 Barrel 01a.jpg | |Step_Picture_00=PPla 1 Barrel 01a.jpg | ||

|Step_Picture_01=PPla 1 Barrel 01b.jpg | |Step_Picture_01=PPla 1 Barrel 01b.jpg | ||

| Ligne 72 : | Ligne 75 : | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=Barrel | + | |Step_Title=<translate><!--T:13--> Barrel</translate> |

|Step_Picture_00=PPla 1 Barrel 02.jpg | |Step_Picture_00=PPla 1 Barrel 02.jpg | ||

}} | }} | ||

| Ligne 99 : | Ligne 102 : | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

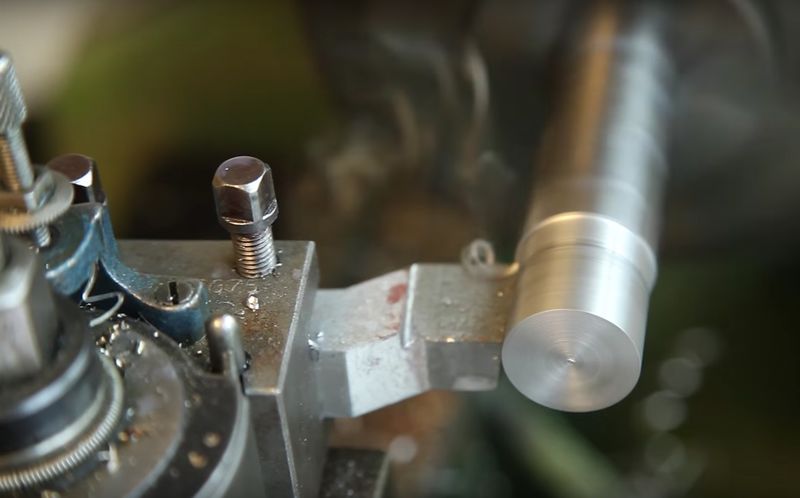

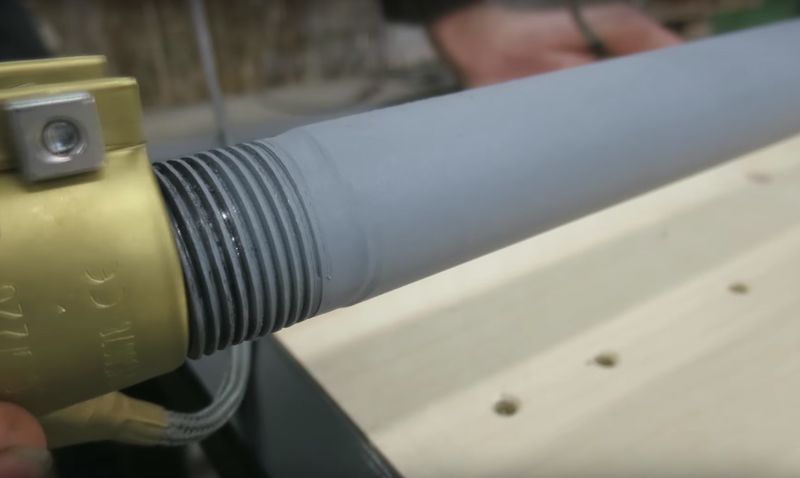

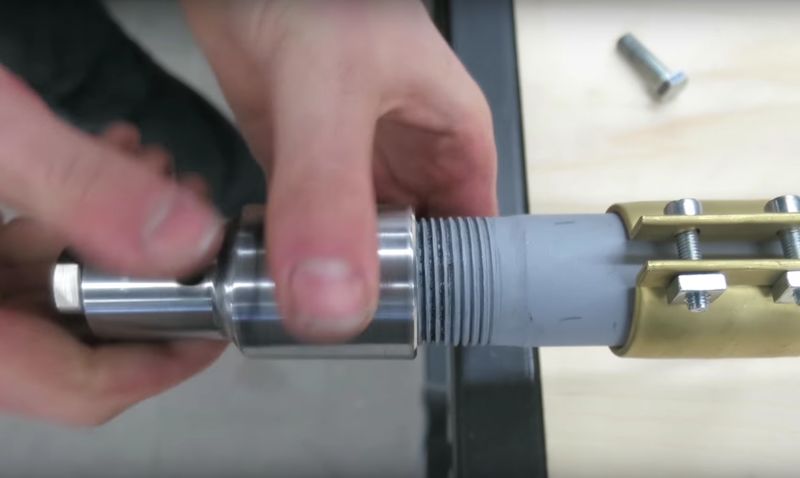

| − | |Step_Title=Nozzle | + | |Step_Title=<translate><!--T:14--> Nozzle</translate> |

|Step_Picture_00=PP nozzle 01a.jpg | |Step_Picture_00=PP nozzle 01a.jpg | ||

|Step_Picture_01=PP nozzle 01b.jpg | |Step_Picture_01=PP nozzle 01b.jpg | ||

| Ligne 131 : | Ligne 134 : | ||

}} | }} | ||

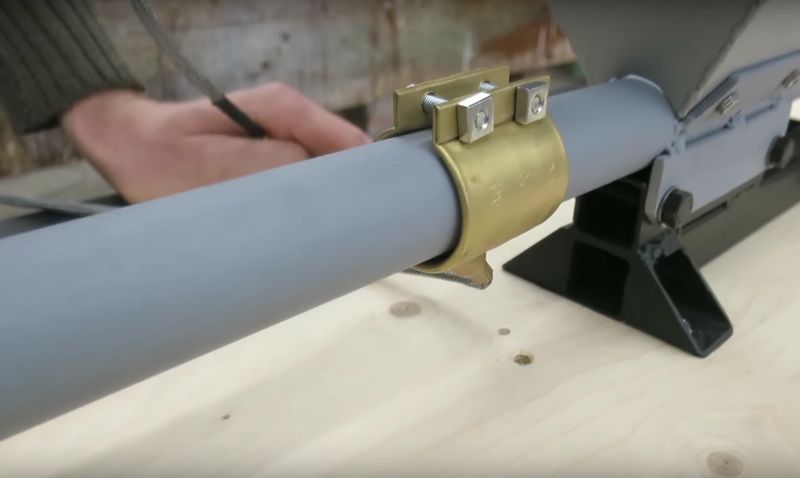

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=Barrel holder | + | |Step_Title=<translate><!--T:15--> Barrel holder</translate> |

|Step_Picture_00=PP barrel holderZ 01a.jpg | |Step_Picture_00=PP barrel holderZ 01a.jpg | ||

|Step_Picture_01=PP barrel holderZ 01b.jpg | |Step_Picture_01=PP barrel holderZ 01b.jpg | ||

| Ligne 157 : | Ligne 160 : | ||

}} | }} | ||

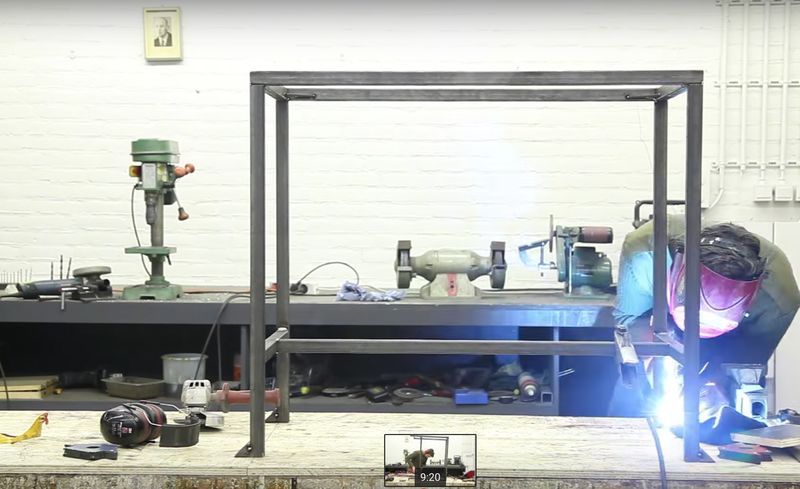

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=Framework | + | |Step_Title=<translate><!--T:16--> Framework</translate> |

|Step_Picture_00=PP framework 01a.jpg | |Step_Picture_00=PP framework 01a.jpg | ||

|Step_Picture_01=PP framework 01b.jpg | |Step_Picture_01=PP framework 01b.jpg | ||

| Ligne 215 : | Ligne 218 : | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=Attach it to the frame | + | |Step_Title=<translate><!--T:17--> Attach it to the frame</translate> |

|Step_Picture_00=PP ElecConnect 03a.jpg | |Step_Picture_00=PP ElecConnect 03a.jpg | ||

}} | }} | ||

| Ligne 232 : | Ligne 235 : | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=Engine | + | |Step_Title=<translate><!--T:18--> Engine</translate> |

|Step_Picture_00=PP Engine.gif | |Step_Picture_00=PP Engine.gif | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=Improvements and learn | + | |Step_Title=<translate><!--T:19--> Improvements and learn</translate> |

| − | |Step_Content='''Suggestion:''' Currently, the nose decided the amount of plastic that comes out. | + | |Step_Content=<translate><!--T:20--> |

| + | '''Suggestion:''' Currently, the nose decided the amount of plastic that comes out. | ||

| + | <!--T:21--> | ||

However, a better way to do this is by adding a controllable engine. There are different ways to control the speed of an engine by using different controllers or regulators. | However, a better way to do this is by adding a controllable engine. There are different ways to control the speed of an engine by using different controllers or regulators. | ||

| + | <!--T:22--> | ||

'''How to use the machine''' | '''How to use the machine''' | ||

| + | <!--T:23--> | ||

[https://www.youtube.com/watch?v=p4NoY33-Tfo&t=15m9s Clic here] to watch our online video (starting from 15:09) to learn how to use the machine. | [https://www.youtube.com/watch?v=p4NoY33-Tfo&t=15m9s Clic here] to watch our online video (starting from 15:09) to learn how to use the machine. | ||

| − | Thanks! | + | <!--T:24--> |

| + | Thanks!</translate> | ||

|Step_Picture_00=Machine-extrusion.jpg | |Step_Picture_00=Machine-extrusion.jpg | ||

|Step_Picture_01=PP Final 01.gif | |Step_Picture_01=PP Final 01.gif | ||

|Step_Picture_02=PP Final 02.gif | |Step_Picture_02=PP Final 02.gif | ||

}} | }} | ||

| − | {{Notes}} | + | {{Notes|}} |

{{Tuto_Status | {{Tuto_Status | ||

| − | |Complete= | + | |Complete=Published |

}} | }} | ||

Version actuelle datée du 9 décembre 2019 à 11:49

Sommaire

- 1 Introduction

- 2 Étape 1 - Hopper: cutting metal plates

- 3 Étape 2 - Hopper: drilling metal plates

- 4 Étape 3 - Hopper: welding metal plates

- 5 Étape 4 - Hopper finishes

- 6 Étape 5 - Barrel

- 7 Étape 6 - Barrel

- 8 Étape 7 -

- 9 Étape 8 -

- 10 Étape 9 -

- 11 Étape 10 -

- 12 Étape 11 -

- 13 Étape 12 - Nozzle

- 14 Étape 13 -

- 15 Étape 14 -

- 16 Étape 15 -

- 17 Étape 16 -

- 18 Étape 17 -

- 19 Étape 18 - Barrel holder

- 20 Étape 19 -

- 21 Étape 20 -

- 22 Étape 21 -

- 23 Étape 22 -

- 24 Étape 23 - Framework

- 25 Étape 24 -

- 26 Étape 25 -

- 27 Étape 26 -

- 28 Étape 27 -

- 29 Étape 28 -

- 30 Étape 29 -

- 31 Étape 30 -

- 32 Étape 31 -

- 33 Étape 32 -

- 34 Étape 33 - Attach it to the frame

- 35 Étape 34 -

- 36 Étape 35 -

- 37 Étape 36 - Engine

- 38 Étape 37 - Improvements and learn

- 39 Commentaires

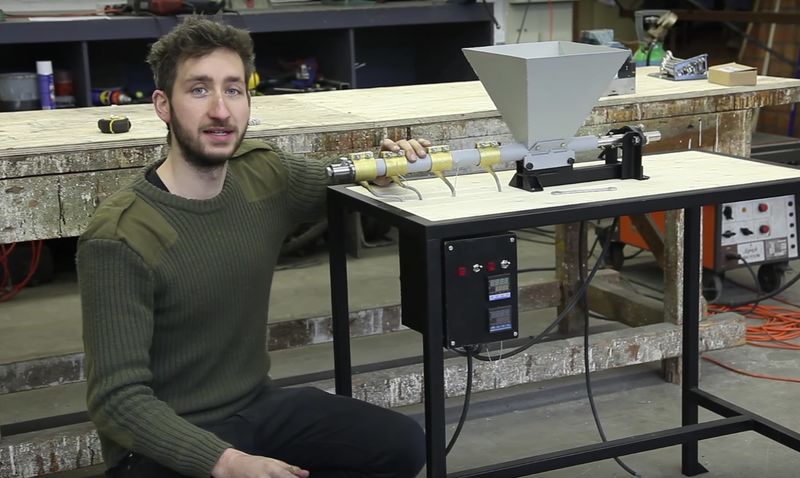

Introduction

The extrusion machine has quite a specific output, a line. This is well suited to make new granulate and 3D printer filament. However use your creativity and you will find other applications for it as well. Change the nozzle for different shapes and sizes, turn it around a mold to make lamps or a handle for a knife.

The extrusion machine consists in 6 different elements: the hopper, the barrel, the nozzle, the barrel holder, the framework and the electronics.

Matériaux

- Metal sheet plates

- Metal tubes

Outils

- Angle grinder

- Protective glasses

- Milling machine

- Arc welding machine

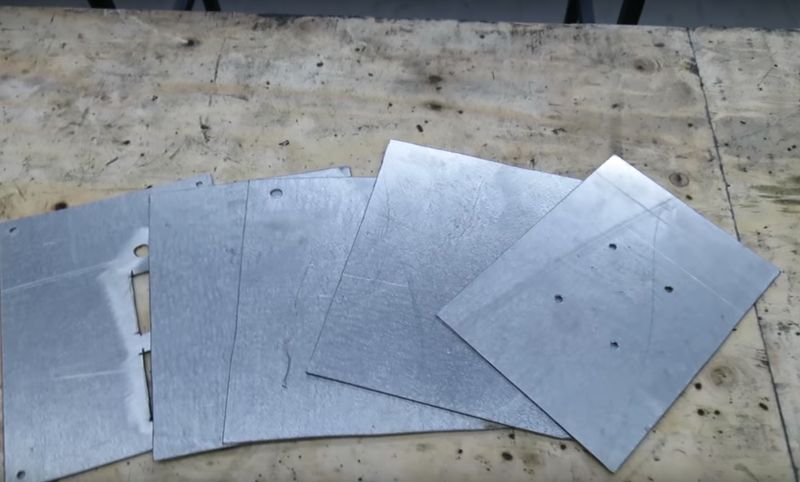

Étape 1 - Hopper: cutting metal plates

Get the metal sheet plates. Take measurements following the blue prints and cut the sheets with a grinding machine and sand metal edges.

Étape 2 - Hopper: drilling metal plates

Prick the plate with a hammer and drill the metal plates on the milling machine

Étape 37 - Improvements and learn

Suggestion: Currently, the nose decided the amount of plastic that comes out.

However, a better way to do this is by adding a controllable engine. There are different ways to control the speed of an engine by using different controllers or regulators.

How to use the machine

Clic here to watch our online video (starting from 15:09) to learn how to use the machine.

Thanks!

Published

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português