(Page créée avec « {{Tuto Details |Description=<translate>The following guide documents the build of the Precious Plastic Sheet Press as supplied and designed by Citizen Scientific Workshop.... ») |

|||

| Ligne 15 : | Ligne 15 : | ||

{{Materials}} | {{Materials}} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate>Top and Bottom Plates (grid structure)</translate> | + | |Step_Title=<translate>Top and Bottom Plates (grid structure 1)</translate> |

|Step_Content=<translate><nowiki>*</nowiki>The following X steps will be used to make 2 identical plate assemblies. The parts listed are for 1 assembly (so double everything if you're making two plates at a time) | |Step_Content=<translate><nowiki>*</nowiki>The following X steps will be used to make 2 identical plate assemblies. The parts listed are for 1 assembly (so double everything if you're making two plates at a time) | ||

| − | ==== Tools ==== | + | ====Tools==== |

1/4"-20 tap + tap handle | 1/4"-20 tap + tap handle | ||

| Ligne 26 : | Ligne 26 : | ||

<br /> | <br /> | ||

| − | ==== Parts ==== | + | ====Parts==== |

1 meter aluminum sheet | 1 meter aluminum sheet | ||

| − | 2x 1000mm | + | 2x 1000mm 4080 extrusion |

| − | 4x | + | 4x 920mm 4080 extrusion |

| − | 4x 286mm | + | 4x 286mm 4080 extrusion |

| − | 2x266mm | + | 2x266mm 4080 extrusion |

156 T-nuts (16*9) + 12) | 156 T-nuts (16*9) + 12) | ||

| Ligne 41 : | Ligne 41 : | ||

156 M8x16mm Bolts | 156 M8x16mm Bolts | ||

| − | + | 156 M8 washers | |

| − | # Tap the 36 pre-drilled 13/64" holes with the 1/4"-20 tap. | + | ====Steps==== |

| − | ## use the countersink bit to clean up any debris. | + | |

| − | # Layout the large extrusion (image 2) so that the 1m sides are parallel, and the 960mm beams are evenly distributed at 90 degrees to the 1m beams. | + | #Tap the 36 pre-drilled 13/64" holes with the 1/4"-20 tap. |

| − | # Insert 12 t-nuts (6 in each row) into each extrusion face that faces the inside of the plate. (image 2). 8 faces total(4 from exterior beams, and 4 from each side of the two interior beams. 96 nuts total | + | ##use the countersink bit to clean up any debris. |

| − | # Position the two 266mm beams in the center row, splitting it into 3 equal sections. | + | #Layout the large extrusion (image 2) so that the 1m sides are parallel, and the 960mm beams are evenly distributed at 90 degrees to the 1m beams. |

| − | # Position the four 286mm beams in the top and bottom rows, matching the position of the 266 beams. | + | #Insert 12 t-nuts (6 in each row) into each extrusion face that faces the inside of the plate. (image 2). 8 faces total(4 from exterior beams, and 4 from each side of the two interior beams. 96 nuts total |

| − | # For each | + | #Position the two 266mm beams in the center row, splitting it into 3 equal sections. |

| + | #Position the four 286mm beams in the top and bottom rows, matching the position of the 266 beams. | ||

| + | #For each 80mm face of these interior beams, place 4 t nuts (2 in each slot). Be sure to place these on both faces. 48 nuts total. <br /> | ||

'''Attaching the exterior beams to the plate''' | '''Attaching the exterior beams to the plate''' | ||

| − | # On the bottom | + | #On the bottom 40mm face, slide 4 t nuts into each 1000mm beam. (image 4) |

| − | # Match these T nuts with the holes in the plate as this will be a "blind" install. (image 5) | + | #Match these T nuts with the holes in the plate as this will be a "blind" install. (image 5) |

| − | # slide the plate off your work area so you can access the holes from below. | + | #slide the plate off your work area so you can access the holes from below. |

| − | # Place the extrusion directly on top of the plate ensuring not to shift it off its alignment. | + | #Place the extrusion directly on top of the plate ensuring not to shift it off its alignment. |

| − | # Using the M8 bolts, secure the beam to the plate. | + | #Using the M8 bolts, secure the beam to the plate. |

| − | # Repeat this process until you have attached both 1000mm beams and 960mm beams. (12 bolts total)</translate> | + | #Repeat this process until you have attached both 1000mm beams and 960mm beams. (12 bolts total)</translate> |

|Step_Picture_00=PP_Sheetpress_PXL_20220111_174002949.jpg | |Step_Picture_00=PP_Sheetpress_PXL_20220111_174002949.jpg | ||

|Step_Picture_01=PP_Sheetpress_PXL_20220111_180820186.jpg | |Step_Picture_01=PP_Sheetpress_PXL_20220111_180820186.jpg | ||

| Ligne 65 : | Ligne 67 : | ||

|Step_Picture_04=PP_Sheetpress_PXL_20220111_192321011.jpg | |Step_Picture_04=PP_Sheetpress_PXL_20220111_192321011.jpg | ||

|Step_Picture_05=PP_Sheetpress_PXL_20220111_192655317.jpg | |Step_Picture_05=PP_Sheetpress_PXL_20220111_192655317.jpg | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Top and Bottom Plates (grid structure 2)</translate> | ||

| + | |Step_Content=<translate>====Tools==== | ||

| + | same as above | ||

| + | |||

| + | ====Parts==== | ||

| + | 36 corner brackets | ||

| + | |||

| + | ====Steps==== | ||

| + | |||

| + | # Prepare your parts. Each "cell" will require 4 brackets, 16 M8Bolts, and 16 washers | ||

| + | # Starting with the 4 corners of the ''entire assembly'', attach the corner brackets and tighten the bolts only to finger-tight. | ||

| + | # Next attach the 920 beam ends to the outer perimeter. | ||

| + | # Next, attach the inner beams in place. Ensure that all beams are equally spaced. (remember that the 2 interior beams are shorter though) <br /></translate> | ||

| + | |Step_Picture_00=PP_Sheetpress_PXL_20220111_195719974.jpg | ||

| + | |Step_Picture_01=PP_Sheetpress_PXL_20220111_204734409.jpg | ||

| + | |Step_Picture_02=PP_Sheetpress_PXL_20220111_204729651.jpg | ||

}} | }} | ||

{{Notes | {{Notes | ||

Version du 11 janvier 2022 à 23:03

The following guide documents the build of the Precious Plastic Sheet Press as supplied and designed by Citizen Scientific Workshop.

Difficulté

Difficile

Durée

5 jour(s)

Catégories

Recyclage & Upcycling

Coût

7000 EUR (€)

Matériaux

Outils

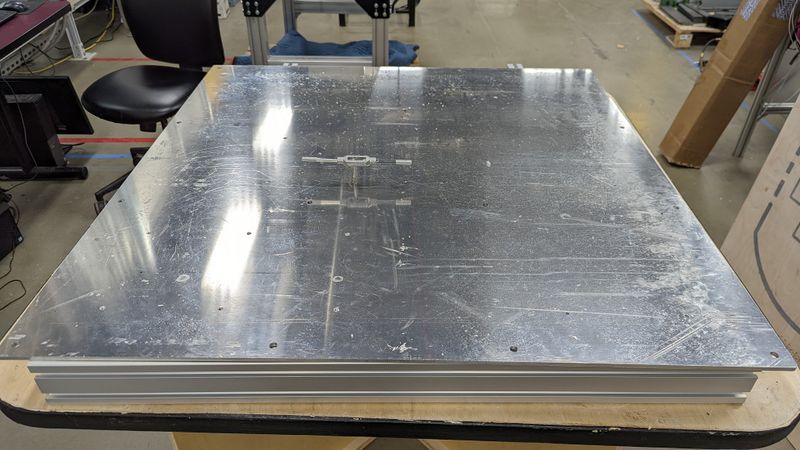

Étape 1 - Top and Bottom Plates (grid structure 1)

*The following X steps will be used to make 2 identical plate assemblies. The parts listed are for 1 assembly (so double everything if you're making two plates at a time)

Tools

1/4"-20 tap + tap handle

countersink (or anything over 1/4" bit) for hole cleanup

1/2" Socket

Parts

1 meter aluminum sheet

2x 1000mm 4080 extrusion

4x 920mm 4080 extrusion

4x 286mm 4080 extrusion

2x266mm 4080 extrusion

156 T-nuts (16*9) + 12)

156 M8x16mm Bolts

156 M8 washers

Steps

- Tap the 36 pre-drilled 13/64" holes with the 1/4"-20 tap.

- use the countersink bit to clean up any debris.

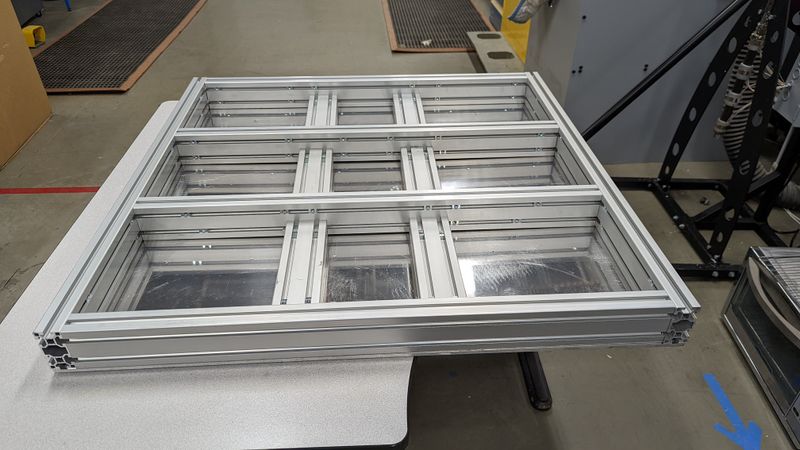

- Layout the large extrusion (image 2) so that the 1m sides are parallel, and the 960mm beams are evenly distributed at 90 degrees to the 1m beams.

- Insert 12 t-nuts (6 in each row) into each extrusion face that faces the inside of the plate. (image 2). 8 faces total(4 from exterior beams, and 4 from each side of the two interior beams. 96 nuts total

- Position the two 266mm beams in the center row, splitting it into 3 equal sections.

- Position the four 286mm beams in the top and bottom rows, matching the position of the 266 beams.

- For each 80mm face of these interior beams, place 4 t nuts (2 in each slot). Be sure to place these on both faces. 48 nuts total.

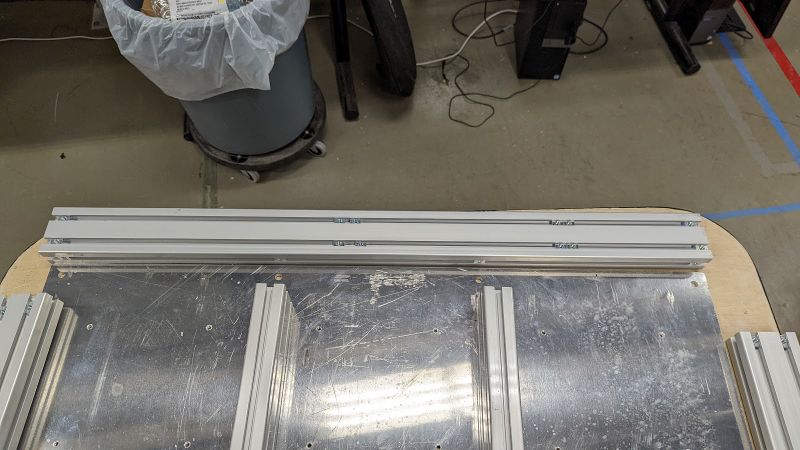

Attaching the exterior beams to the plate

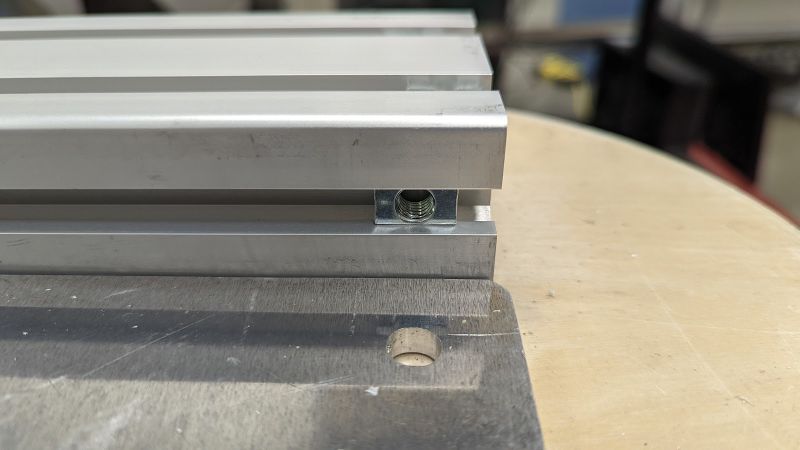

- On the bottom 40mm face, slide 4 t nuts into each 1000mm beam. (image 4)

- Match these T nuts with the holes in the plate as this will be a "blind" install. (image 5)

- slide the plate off your work area so you can access the holes from below.

- Place the extrusion directly on top of the plate ensuring not to shift it off its alignment.

- Using the M8 bolts, secure the beam to the plate.

- Repeat this process until you have attached both 1000mm beams and 960mm beams. (12 bolts total)

Étape 2 - Top and Bottom Plates (grid structure 2)

Tools

same as above

Parts

36 corner brackets

Steps

- Prepare your parts. Each "cell" will require 4 brackets, 16 M8Bolts, and 16 washers

- Starting with the 4 corners of the entire assembly, attach the corner brackets and tighten the bolts only to finger-tight.

- Next attach the 920 beam ends to the outer perimeter.

- Next, attach the inner beams in place. Ensure that all beams are equally spaced. (remember that the 2 interior beams are shorter though)

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português