(Page créée avec « {{Tuto Details |Description=<translate>Over a delicious pizza dinner at The Makerspace (Durban), the Innovative Waste Design (IWD) team took off with a great problem, the... ») |

|||

| (2 révisions intermédiaires par le même utilisateur non affichées) | |||

| Ligne 1 : | Ligne 1 : | ||

{{Tuto Details | {{Tuto Details | ||

| + | |Main_Picture=Recycled_Plastic_Products_combs.JPG | ||

| + | |Main_Picture_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":51,"top":-72,"width":1984,"height":2976,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.25,"scaleY":0.25,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://wikifab.org/images/b/b4/Recycled_Plastic_Products_combs.JPG","filters":[]}],"height":450,"width":600} | ||

|Description=<translate>Over a delicious pizza dinner at The Makerspace (Durban), the Innovative Waste Design (IWD) team took off with a great problem, the waste from our take outs. Fact is, the current linear plastic packaging lifecycle is extremely wasteful and harmful to the environment yet waste is more valuable than people think and know it to be. | |Description=<translate>Over a delicious pizza dinner at The Makerspace (Durban), the Innovative Waste Design (IWD) team took off with a great problem, the waste from our take outs. Fact is, the current linear plastic packaging lifecycle is extremely wasteful and harmful to the environment yet waste is more valuable than people think and know it to be. | ||

| Ligne 15 : | Ligne 17 : | ||

}} | }} | ||

{{Materials}} | {{Materials}} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Intro</translate> | ||

| + | |Step_Content=<translate></translate> | ||

| + | |Step_Picture_00=Recycled_Plastic_Products_intro.mp4 | ||

| + | }} | ||

{{Tuto Step | {{Tuto Step | ||

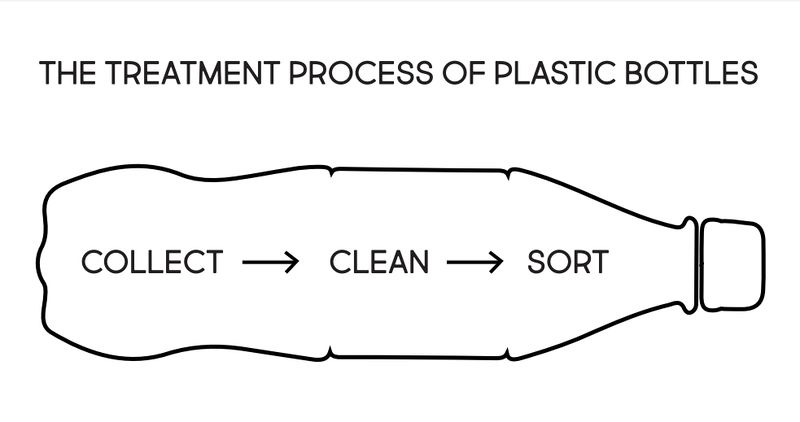

|Step_Title=<translate>Treatment</translate> | |Step_Title=<translate>Treatment</translate> | ||

|Step_Content=<translate>Making products out of recycled plastic caps, it is very important to ensure that all contaminants have been removed for a better quality.</translate> | |Step_Content=<translate>Making products out of recycled plastic caps, it is very important to ensure that all contaminants have been removed for a better quality.</translate> | ||

| + | |Step_Picture_00=Recycled_Plastic_Products_WhatsApp_Image_2020-12-13_at_9.24.11_PM.jpeg | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Shred Plastic</translate> |

|Step_Content=<translate>Once the treatment process has been completed we take the bottle caps into the shredder where the outcome is crushed plastic flakes.</translate> | |Step_Content=<translate>Once the treatment process has been completed we take the bottle caps into the shredder where the outcome is crushed plastic flakes.</translate> | ||

| + | |Step_Picture_00=Recycled_Plastic_Products_WhatsApp_Image_2020-12-13_at_9.24.14_PM.jpeg | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Mold Injection</translate> |

|Step_Content=<translate>We insert the plastic flakes into the plastic prenuer injection moulding machine, while the injector is melting the flakes into a solution, it is best to use the time to heat up the aluminum mold.</translate> | |Step_Content=<translate>We insert the plastic flakes into the plastic prenuer injection moulding machine, while the injector is melting the flakes into a solution, it is best to use the time to heat up the aluminum mold.</translate> | ||

| + | |Step_Picture_00=Recycled_Plastic_Products_IMG-20200511-WA0065.jpg | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Final Product</translate> |

|Step_Content=<translate>When the solution is melted and ready, turn the wheel in order to extrude the melted plastic into the mold. | |Step_Content=<translate>When the solution is melted and ready, turn the wheel in order to extrude the melted plastic into the mold. | ||

| Ligne 34 : | Ligne 44 : | ||

The final product will have access plastic that you will remove by trimming and sanding for a smooth finish. And that is how you get a product made 100% from recycled plastic and that is 100% recyclable.</translate> | The final product will have access plastic that you will remove by trimming and sanding for a smooth finish. And that is how you get a product made 100% from recycled plastic and that is 100% recyclable.</translate> | ||

| + | |Step_Picture_00=Recycled_Plastic_Products_IMG_9569.JPG | ||

| + | |Step_Picture_01=Recycled_Plastic_Products_IMG_9541.JPG | ||

}} | }} | ||

{{Notes | {{Notes | ||

| Ligne 39 : | Ligne 51 : | ||

}} | }} | ||

{{PageLang | {{PageLang | ||

| + | |Language=en | ||

|SourceLanguage=none | |SourceLanguage=none | ||

|IsTranslation=0 | |IsTranslation=0 | ||

| − | |||

}} | }} | ||

{{Tuto Status | {{Tuto Status | ||

| − | |Complete= | + | |Complete=Published |

}} | }} | ||

Version actuelle datée du 13 décembre 2020 à 20:50

Introduction

Matériaux

Outils

Étape 1 - Intro

Étape 2 - Treatment

Making products out of recycled plastic caps, it is very important to ensure that all contaminants have been removed for a better quality.

Étape 3 - Shred Plastic

Once the treatment process has been completed we take the bottle caps into the shredder where the outcome is crushed plastic flakes.

Étape 4 - Mold Injection

We insert the plastic flakes into the plastic prenuer injection moulding machine, while the injector is melting the flakes into a solution, it is best to use the time to heat up the aluminum mold.

Étape 5 - Final Product

When the solution is melted and ready, turn the wheel in order to extrude the melted plastic into the mold.

Cool down the mold by placing into a bucket of cold water. Take the mold out of the water and unscrew the bolts for the grand reveal.

The final product will have access plastic that you will remove by trimming and sanding for a smooth finish. And that is how you get a product made 100% from recycled plastic and that is 100% recyclable.

Published

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português