| Ligne 1 : | Ligne 1 : | ||

{{ {{tntn|Tuto Details}} | {{ {{tntn|Tuto Details}} | ||

| − | |||

| − | |||

| − | |||

|Main_Picture=Open_Workshop_Setup_OpenWorkshopSetup-new-15.jpg | |Main_Picture=Open_Workshop_Setup_OpenWorkshopSetup-new-15.jpg | ||

|Licences=Attribution-ShareAlike (CC BY-SA) | |Licences=Attribution-ShareAlike (CC BY-SA) | ||

| Ligne 14 : | Ligne 11 : | ||

|Currency=USD ($) | |Currency=USD ($) | ||

|Tags=Workshop, Tools, Materials, Open Source Hardware, Management | |Tags=Workshop, Tools, Materials, Open Source Hardware, Management | ||

| + | |SourceLanguage=none | ||

| + | |Language=en | ||

| + | |IsTranslation=0 | ||

}} | }} | ||

{{ {{tntn|Introduction}} | {{ {{tntn|Introduction}} | ||

| Ligne 69 : | Ligne 69 : | ||

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

|Step_Title=Fix the boards to the wall | |Step_Title=Fix the boards to the wall | ||

| − | |Step_Content= | + | |Step_Content=* Use nails (inches 1.5,2,3) |

| + | |||

| + | * hammer for hammering the nails on the board. | ||

| + | |||

| + | * Build up some boxes for materials like markers. | ||

| + | |||

| + | * Draw the shapes of the materials and tools for easy identification after use. | ||

|Step_Picture_00=Open_Workshop_Setup_OpenWorkshopSetup-new-5.jpg | |Step_Picture_00=Open_Workshop_Setup_OpenWorkshopSetup-new-5.jpg | ||

|Step_Picture_01=Open_Workshop_Setup_OpenWorkshopSetup-new-13.jpg | |Step_Picture_01=Open_Workshop_Setup_OpenWorkshopSetup-new-13.jpg | ||

| Ligne 77 : | Ligne 83 : | ||

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

|Step_Title=Fix tools and materials to the boards and finish up | |Step_Title=Fix tools and materials to the boards and finish up | ||

| − | |Step_Content= | + | |Step_Content=* Tools and materials should be fixed based on there shapes. |

| + | |||

| + | * Balance both sides to reduce more weight on one side | ||

|Step_Picture_00=Open_Workshop_Setup_OpenWorkshopSetup-new-18.jpg | |Step_Picture_00=Open_Workshop_Setup_OpenWorkshopSetup-new-18.jpg | ||

|Step_Picture_01=Open_Workshop_Setup_OpenWorkshopSetup-new-17.jpg | |Step_Picture_01=Open_Workshop_Setup_OpenWorkshopSetup-new-17.jpg | ||

| Ligne 86 : | Ligne 94 : | ||

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

|Step_Title=Tips & WATCH YOUR TOOLS | |Step_Title=Tips & WATCH YOUR TOOLS | ||

| − | |Step_Content= | + | |Step_Content=* Always ensure the open training space is neat and clean. |

| + | |||

| + | * Keep off children near the work space. | ||

| + | |||

| + | * The work space should be dust free at all times | ||

| + | |||

| + | * Ensure to bring back tools and materials taken from the work space. | ||

| + | |||

| + | * Should be free from water since some of the tools rusts. | ||

|Step_Picture_00=Open_Workshop_Setup_OpenWorkshopSetup-new-24.jpg | |Step_Picture_00=Open_Workshop_Setup_OpenWorkshopSetup-new-24.jpg | ||

|Step_Picture_01=Open_Workshop_Setup_OpenWorkshopSetup-new-23.jpg | |Step_Picture_01=Open_Workshop_Setup_OpenWorkshopSetup-new-23.jpg | ||

Version du 6 décembre 2018 à 15:58

Create a simple worspace setup to manage and organise your tools and materials

Difficulté

Facile

Durée

8 heure(s)

Catégories

Électronique, Machines & Outils, Recyclage & Upcycling

Coût

100 USD ($)

Introduction

Creating a organised workshop is key for your active work on projects.

So we came up with a simple and cheap way of doing it, the more material you upcycle to build it, the more you can reduce the costs.

Matériaux

- 2x plywood (90x60cm, 90x120cm)

- nails (100, 60, 40, 25 mm)

- timber (for the box) + leftover plywood sheets

- long timber (120x7cm)

- boxes

- water bottles (1.0 & 0.5 l)

- solid wooden table (120x70x90cm)

Outils

- hammer

- saw

- sissors

- tape measure

- water level

- square

- sandpaper

- documentation camera/smartphone cam

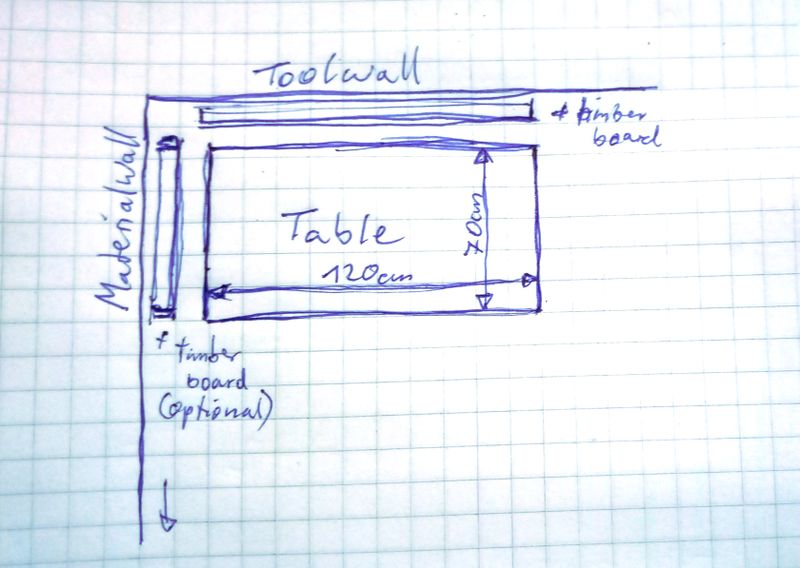

Étape 1 - Space selection & preparation

- You need a space where you can work, so at least 8x bigger than your original workshop spot

- use a corner of the room (about 2.0x1.0m Space minimum)

- keep lights and accessebillity in mind

- kreate an overview of tools and materials you have

- start looking for a good sized plywood for your tools (big) and your small materials (small)

- use a solid table as base for the construction (at least 90cm high and 70cm deep)

- have a powerplug close to it

- cut the wood sheets

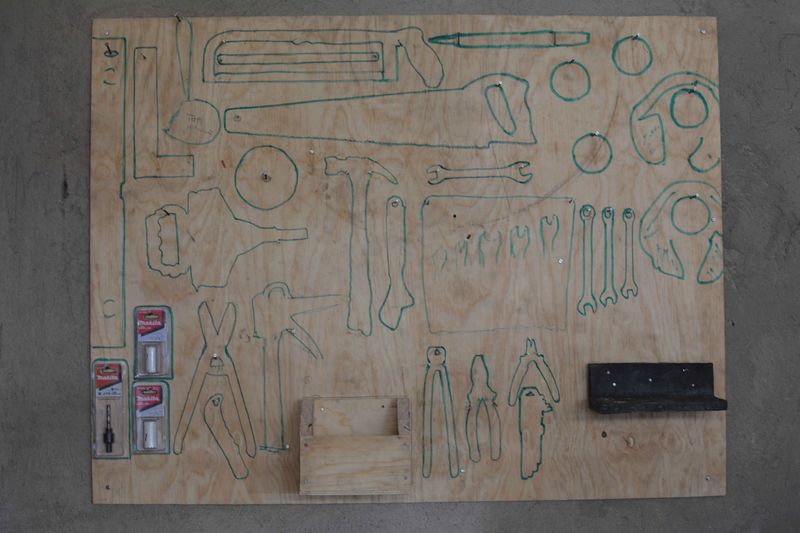

Étape 2 - prepare tools & materials

- sort materials and tools by type and usage

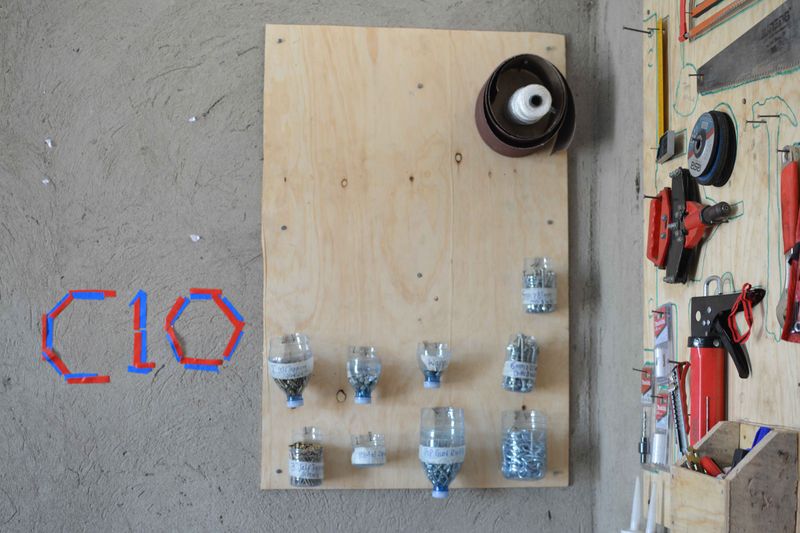

- cut the bottles to fill with materials (screws, bolts, nuts, washers, hooks, rivets etc.)

- place the tools in order on the ground to the sheet (try different setups)

- draw a fine line with a pencil around the tools

- cut the parts for the box and the skrewdriver board and add it to the wall setup

- nail everything to the board and remove the tools

Étape 3 - Fix the boards to the wall

- Use nails (inches 1.5,2,3)

- hammer for hammering the nails on the board.

- Build up some boxes for materials like markers.

- Draw the shapes of the materials and tools for easy identification after use.

Étape 4 - Fix tools and materials to the boards and finish up

- Tools and materials should be fixed based on there shapes.

- Balance both sides to reduce more weight on one side

Étape 5 - Tips & WATCH YOUR TOOLS

- Always ensure the open training space is neat and clean.

- Keep off children near the work space.

- The work space should be dust free at all times

- Ensure to bring back tools and materials taken from the work space.

- Should be free from water since some of the tools rusts.

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português