(Page créée avec « Fabriquez un refuge pour chat sauvage, ou une maison pour votre ami à fourrure. ») |

|||

| Ligne 2 : | Ligne 2 : | ||

|Main_Picture=FabCat_House_03_sm.jpg | |Main_Picture=FabCat_House_03_sm.jpg | ||

|Licences=Attribution-ShareAlike (CC BY-SA) | |Licences=Attribution-ShareAlike (CC BY-SA) | ||

| − | |Description= | + | |Description=Maison en bois pour votre ami à fourrure. |

|Area=Decoration, Furniture, House, Sport and Outside, Play and Hobbies | |Area=Decoration, Furniture, House, Sport and Outside, Play and Hobbies | ||

|Type=Creation | |Type=Creation | ||

Version du 3 août 2018 à 14:08

Sommaire

- 1 Introduction

- 2 Étape 1 - Laser cut

- 3 Étape 2 - Assembly

- 4 Étape 3 - Protection (optional)

- 5 Étape 4 - Cord & Metal Tent Pegs (optional)

- 6 Étape 5 - Cork Sheet/roll or Insulation Board (optional)

- 7 Étape 6 - 3D Printer + 3D Printed Leg Protection + Silicon Glue (optional)

- 8 Étape 7 - Result

- 9 Notes et références

- 10 Commentaires

Introduction

Download, faricate & construct a shelter for a stray cat, or a house for your furry friend.

You only need couple of plywood boards to cut on laser with working area min. 800x500mmIf requested I'll try to do an adaptation for 700x500.

Once you've done fabricating, please, fill in my short survey on how did you make your FabCat House on the project website as well.

Matériaux

- 6 planks of plywood - 800x500

- 1 plank of plywood - 400x300

- Optional:

- Varnish

- Wood stain

Outils

- Laser

Étape 1 - Laser cut

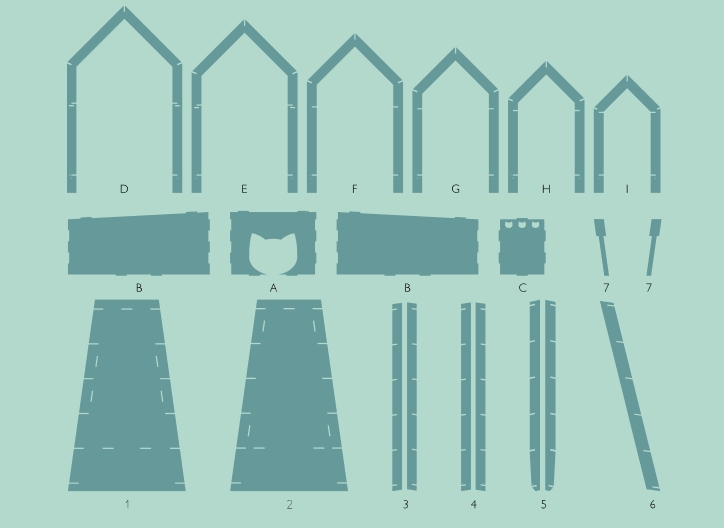

These are the parts you should cut on laser cutter. Consider using wood stain and first layer of varnish before the assembly

You need to cut the planks into the pieces using a laser cutter with working area min. 80x50cm (31.5 x 19.7 inch).

You can get an access to this machines in various places - fablabs, makerspaces, hackerspaces or commercial services like TechShop or others.

- Map of fablabs: www.fablabs.io/labs/map

- Map of fablabs and other labs: www.makery.info/en/map-labs

- Map of makerspaces: themakermap.com

There’s much more, not all of the places are listed in all maps, you can also try to research it by yourself.

Étape 2 - Assembly

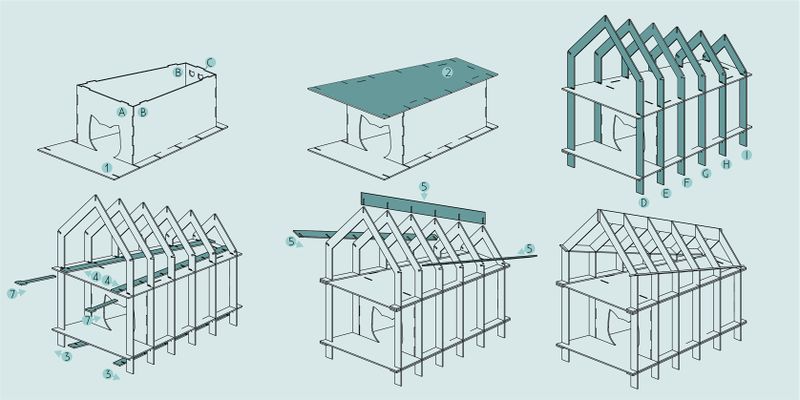

Follow the steps to assembly the object, it shouldn't take you long. If the thickness of the planks is right, you shouldn't need to use any glue.

Étape 3 - Protection (optional)

Depending on how solid and resistant you want your house to be you can apply wood stain and varnish. For exterior use, varnish is absolutely necessary.

Wood stain/finish can provide additional protection and a nice finish to your object. You can choose different types and colors.

Varnish (marine or other type) is a great tool to make your object resistant to humidity or insects and give it a nice finish. Also, after assembling the object, it will glue it together and fill in small cracks.

Apply varnish and wood stain with a brush. Don’t forget to wash it really good after each use.

Étape 4 - Cord & Metal Tent Pegs (optional)

At the bottom of the house's ribs you can find set of 3mm holes.

If necessary, you can use them to fix the house to the ground using a cord and metal tent pegs.

Étape 5 - Cork Sheet/roll or Insulation Board (optional)

Depending on where you live, there’s a possibility that you will want to protect cats from the cold weather. There are multiple options, for extreme cold you could install rigid insulation boards or cork sheets (2 or more mm)

Both are very easy to cut with scissors or cutter (cork even with laser cutter).

Étape 6 - 3D Printer + 3D Printed Leg Protection + Silicon Glue (optional)

If you want to use this object in exterior you need to protect its wooden legs against the humidity. One of the options is to print leg protection on a 3D printer.

This option can be useful also if you want to protect your floor. It is possible that the print will still be sharp so you will have to sand it on the edges.

Notes et références

Project website : fabcat.gregor-design.eu

THANK YOU VERY MUCH!! :) Btw. If you have any propositions on improvement I invite you to contact me!

Also, I invite you to fill in my survey on makers movement on the project website.

Published

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português