(Mise à jour pour être en accord avec la nouvelle version de la source de la page) |

(update property name) |

||

| (Une révision intermédiaire par un autre utilisateur non affichée) | |||

| Ligne 1 : | Ligne 1 : | ||

| − | {{ | + | {{Tuto Details |

| + | |Main_Picture=Salad_tongs_der_des_ders.png | ||

| + | |Licences=Attribution (CC BY) | ||

| + | |Description=A nice set of wooden salad tongs. | ||

| + | |Area=Food and Agriculture, Furniture, House | ||

|Type=Creation | |Type=Creation | ||

| − | |||

| − | |||

| − | |||

|Difficulty=Hard | |Difficulty=Hard | ||

| + | |Duration=4 | ||

| + | |Duration-type=hour(s) | ||

|Cost=50 | |Cost=50 | ||

|Currency=USD ($) | |Currency=USD ($) | ||

| − | | | + | |Tags=tongs, wood |

| − | |||

| − | |||

| − | |||

|SourceLanguage=none | |SourceLanguage=none | ||

|Language=en | |Language=en | ||

|IsTranslation=1 | |IsTranslation=1 | ||

}} | }} | ||

| − | {{ | + | {{Introduction |

|Introduction=I made this simple pair of salad tongs, but we also wanted a geeky, over-the-top pair that looked like the Infinity Gauntlet ([[Infinity Gauntlet Salad Tongs|see the tutorial on Wikifab]]). | |Introduction=I made this simple pair of salad tongs, but we also wanted a geeky, over-the-top pair that looked like the Infinity Gauntlet ([[Infinity Gauntlet Salad Tongs|see the tutorial on Wikifab]]). | ||

}} | }} | ||

| − | {{ | + | {{TutoVideo |

|TutoVideoService=youtube | |TutoVideoService=youtube | ||

|TutoVideoURL=https://youtu.be/EKh4onHwuGI | |TutoVideoURL=https://youtu.be/EKh4onHwuGI | ||

}} | }} | ||

| − | {{ | + | {{Materials |

|Material=Block of basswood | |Material=Block of basswood | ||

| Ligne 36 : | Ligne 36 : | ||

Torch and aluminium rode | Torch and aluminium rode | ||

}} | }} | ||

| − | {{ | + | {{Separator}} |

| − | {{ | + | {{Tuto Step |

| + | |Step_Title=Cut down the rough wood | ||

| + | |Step_Content=For the functional tongs, I use a large chunk of basswood. I drew out the spatula-like shape on the face and cut the thick piece of wood on the band saw. I then turned the piece on its side and resawed the basswood into my two handles. These two halves were still pretty thick and the shape was not yet finalized, all of that would be done with the sanders. | ||

|Step_Picture_00=Salad_tongs__tape_1.png | |Step_Picture_00=Salad_tongs__tape_1.png | ||

|Step_Picture_01=Salad_tongs__tape_3aa_retuch.png | |Step_Picture_01=Salad_tongs__tape_3aa_retuch.png | ||

| Ligne 45 : | Ligne 47 : | ||

|Step_Picture_04=Salad_tongs__tape_3d_retuch.png | |Step_Picture_04=Salad_tongs__tape_3d_retuch.png | ||

|Step_Picture_04_annotation={"objects":[{"type":"wfarrow","originX":"center","originY":"center","left":196.25,"top":123.78,"width":10,"height":90,"fill":"rgba(255,0,0,0)","stroke":"red","strokeWidth":2.71,"strokeDashArray":null,"strokeLineCap":"butt","strokeLineJoin":"miter","strokeMiterLimit":10,"scaleX":1.11,"scaleY":1.11,"angle":311.35,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"points":[{"x":10,"y":10},{"x":10,"y":100},{"x":5,"y":90},{"x":10,"y":100},{"x":15,"y":90}]}],"height":"311","width":"600"} | |Step_Picture_04_annotation={"objects":[{"type":"wfarrow","originX":"center","originY":"center","left":196.25,"top":123.78,"width":10,"height":90,"fill":"rgba(255,0,0,0)","stroke":"red","strokeWidth":2.71,"strokeDashArray":null,"strokeLineCap":"butt","strokeLineJoin":"miter","strokeMiterLimit":10,"scaleX":1.11,"scaleY":1.11,"angle":311.35,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"points":[{"x":10,"y":10},{"x":10,"y":100},{"x":5,"y":90},{"x":10,"y":100},{"x":15,"y":90}]}],"height":"311","width":"600"} | ||

| − | |||

| − | |||

}} | }} | ||

| − | {{ | + | {{Tuto Step |

| − | |||

| − | |||

|Step_Title=Add the slot for the aluminum | |Step_Title=Add the slot for the aluminum | ||

|Step_Content=Now here’s your word of warning, the cut I made into the stem of the handles made me a little nervous. In hindsight, I could have made a quick jig to securely hold the pieces while I passed them over the table saw vertically, but I didn’t think of that at the time. Instead, I mitigated all of the risks and carefully passed the skinny end of the handles over the blade to cut in the pocket that would hold the aluminum. | |Step_Content=Now here’s your word of warning, the cut I made into the stem of the handles made me a little nervous. In hindsight, I could have made a quick jig to securely hold the pieces while I passed them over the table saw vertically, but I didn’t think of that at the time. Instead, I mitigated all of the risks and carefully passed the skinny end of the handles over the blade to cut in the pocket that would hold the aluminum. | ||

{{Warning|This ended up working just fine, but be careful.}} | {{Warning|This ended up working just fine, but be careful.}} | ||

| + | |Step_Picture_00=Salad_tongs__tape_2.png | ||

| + | |Step_Picture_01=Salad_tongs__tape_2b_retuch_small.png | ||

}} | }} | ||

| − | {{ | + | {{Tuto Step |

| + | |Step_Title=Shape the wooden handles | ||

| + | |Step_Content=This process involved a lot of patience and a lot of sanding. I flushed up the stem edges with the edges of the aluminum and then used the belt sander to finalize the handles’ overall shape. The two handles were pressed together and sanded simultaneously so that their profiles matched. | ||

| + | |||

| + | The scoop was carved into the paddles by running them over the rounded end of the belt sander. To round over the crisp edges, I clamped the handles to my work bench and used some files to make some comfortable contours. | ||

|Step_Picture_00=Salad_tongs__tape_3.png | |Step_Picture_00=Salad_tongs__tape_3.png | ||

|Step_Picture_01=Salad_tongs_with_logo.png | |Step_Picture_01=Salad_tongs_with_logo.png | ||

| Ligne 63 : | Ligne 67 : | ||

|Step_Picture_04=Salad_tongs_files_logo.png | |Step_Picture_04=Salad_tongs_files_logo.png | ||

|Step_Picture_04_annotation={"objects":[],"height":"338","width":"600"} | |Step_Picture_04_annotation={"objects":[],"height":"338","width":"600"} | ||

| − | |||

| − | |||

| − | |||

| − | |||

}} | }} | ||

| − | {{ | + | {{Tuto Step |

| + | |Step_Title=Drilled out the holes | ||

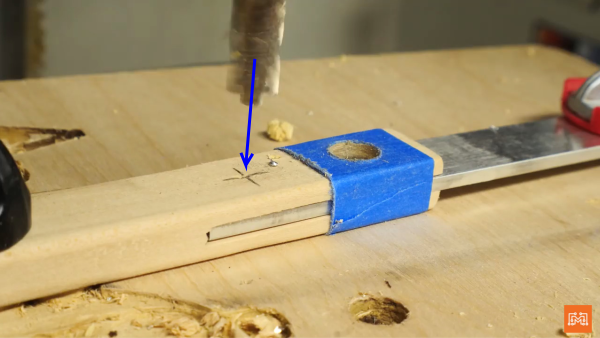

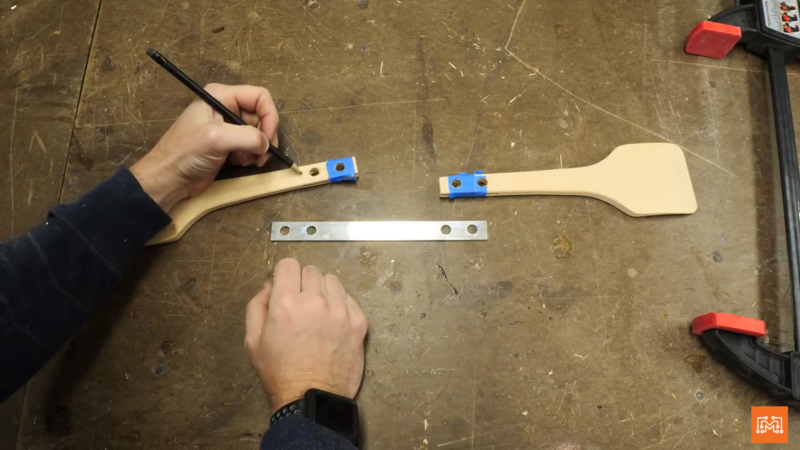

| + | |Step_Content=For the handles, I used some flat aluminum bar stock that I could bend over to act as a spring. Before I bent the metal, I set the flat bar into the slots on the wooden handles and drilled out the holes for the dowels that would connect the pieces with the drill press. I had some 3/8″ aluminum round bar and cut little dowel pieces on the miter saw. Two holes were drilled through both materials so later, I could permanently peg them together. | ||

|Step_Picture_00=Salad_tongs_fini_logo.png | |Step_Picture_00=Salad_tongs_fini_logo.png | ||

|Step_Picture_01=Salad_tongs_mesures_logo.png | |Step_Picture_01=Salad_tongs_mesures_logo.png | ||

|Step_Picture_01_annotation={"objects":[{"type":"wfarrow","originX":"center","originY":"center","left":250.34,"top":112.01,"width":10,"height":90,"fill":"rgba(255,0,0,0)","stroke":"blue","strokeWidth":2.54,"strokeDashArray":null,"strokeLineCap":"butt","strokeLineJoin":"miter","strokeMiterLimit":10,"scaleX":1.18,"scaleY":1.18,"angle":4.69,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"points":[{"x":10,"y":10},{"x":10,"y":100},{"x":5,"y":90},{"x":10,"y":100},{"x":15,"y":90}]}],"height":"338","width":"600"} | |Step_Picture_01_annotation={"objects":[{"type":"wfarrow","originX":"center","originY":"center","left":250.34,"top":112.01,"width":10,"height":90,"fill":"rgba(255,0,0,0)","stroke":"blue","strokeWidth":2.54,"strokeDashArray":null,"strokeLineCap":"butt","strokeLineJoin":"miter","strokeMiterLimit":10,"scaleX":1.18,"scaleY":1.18,"angle":4.69,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"points":[{"x":10,"y":10},{"x":10,"y":100},{"x":5,"y":90},{"x":10,"y":100},{"x":15,"y":90}]}],"height":"338","width":"600"} | ||

|Step_Picture_02=Salad_tongs_finilogo.png | |Step_Picture_02=Salad_tongs_finilogo.png | ||

| − | |||

| − | |||

}} | }} | ||

| − | {{ | + | {{Tuto Step |

| + | |Step_Title=Add the aluminum | ||

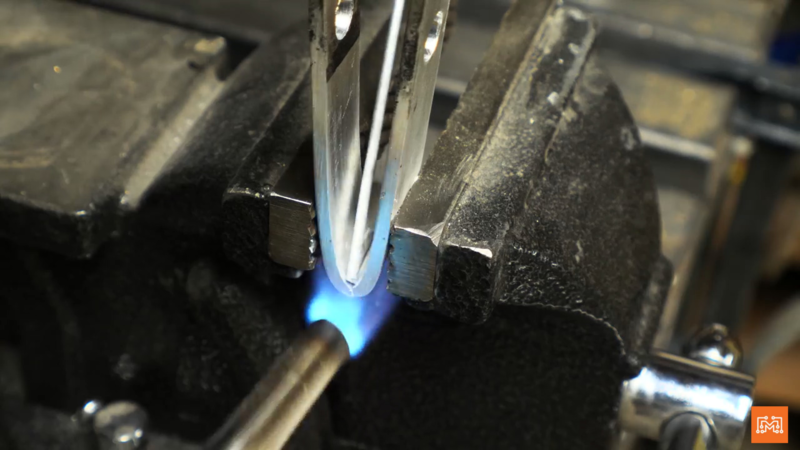

| + | |Step_Content=To bend the flat bar into a spring, I first scored a groove down the center of the piece to act as a fold line. I carefully heated up the aluminum along this line and hammered the piece over into an acute angle. There was an obvious cut line left in the crease that I wanted to cover up. So, I used a torch and some aluminum rod to braise the crease for some extra strength and to give the handles a cleaner look. | ||

|Step_Picture_00=Salad_tongs_lime_logo.png | |Step_Picture_00=Salad_tongs_lime_logo.png | ||

|Step_Picture_01=Salad_tongs_torche_1.png | |Step_Picture_01=Salad_tongs_torche_1.png | ||

| Ligne 83 : | Ligne 85 : | ||

|Step_Picture_03=Salad_tongs_marteau_4.png | |Step_Picture_03=Salad_tongs_marteau_4.png | ||

|Step_Picture_04=Salad_tongs_fondu_5.png | |Step_Picture_04=Salad_tongs_fondu_5.png | ||

| − | |||

| − | |||

}} | }} | ||

| − | {{ | + | {{Tuto Step |

| + | |Step_Title=Drive in the dowels | ||

| + | |Step_Content=All that was left was to drive in the dowels through the attachment holes and secure them in place with some glue. | ||

|Step_Picture_00=Salad_tongs__tape_4.png | |Step_Picture_00=Salad_tongs__tape_4.png | ||

|Step_Picture_01=Salad_tongs_pause.png | |Step_Picture_01=Salad_tongs_pause.png | ||

|Step_Picture_01_annotation={"objects":[{"type":"textbox","originX":"center","originY":"center","left":361,"top":213,"width":54.45,"height":22.6,"fill":"white","stroke":"white","strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeLineJoin":"miter","strokeMiterLimit":10,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"text":"0.5cm","fontSize":20,"fontWeight":"normal","fontFamily":"sans-serif","fontStyle":"","lineHeight":1.16,"textDecoration":"","textAlign":"left","textBackgroundColor":"","charSpacing":0,"minWidth":20,"styles":{"0":{"1":{},"2":{},"3":{},"4":{},"5":{},"6":{},"7":{} } } },{"type":"wfarrow","originX":"center","originY":"center","left":326.31,"top":216.04,"width":10,"height":90,"fill":"rgba(255,0,0,0)","stroke":"white","strokeWidth":6,"strokeDashArray":null,"strokeLineCap":"butt","strokeLineJoin":"miter","strokeMiterLimit":10,"scaleX":0.5,"scaleY":0.5,"angle":177.63,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"points":[{"x":10,"y":10},{"x":10,"y":100},{"x":5,"y":90},{"x":10,"y":100},{"x":15,"y":90}]}],"height":"338","width":"600"} | |Step_Picture_01_annotation={"objects":[{"type":"textbox","originX":"center","originY":"center","left":361,"top":213,"width":54.45,"height":22.6,"fill":"white","stroke":"white","strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeLineJoin":"miter","strokeMiterLimit":10,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"text":"0.5cm","fontSize":20,"fontWeight":"normal","fontFamily":"sans-serif","fontStyle":"","lineHeight":1.16,"textDecoration":"","textAlign":"left","textBackgroundColor":"","charSpacing":0,"minWidth":20,"styles":{"0":{"1":{},"2":{},"3":{},"4":{},"5":{},"6":{},"7":{} } } },{"type":"wfarrow","originX":"center","originY":"center","left":326.31,"top":216.04,"width":10,"height":90,"fill":"rgba(255,0,0,0)","stroke":"white","strokeWidth":6,"strokeDashArray":null,"strokeLineCap":"butt","strokeLineJoin":"miter","strokeMiterLimit":10,"scaleX":0.5,"scaleY":0.5,"angle":177.63,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"points":[{"x":10,"y":10},{"x":10,"y":100},{"x":5,"y":90},{"x":10,"y":100},{"x":15,"y":90}]}],"height":"338","width":"600"} | ||

|Step_Picture_02=Salad_tongs_colle_logo.png | |Step_Picture_02=Salad_tongs_colle_logo.png | ||

| − | |||

| − | |||

}} | }} | ||

| − | {{ | + | {{Tuto Step |

| + | |Step_Title=Finish with oil | ||

| + | |Step_Content=Because this piece will be touching food, I used a butcher block conditioner meant for cutting boards. This product is food safe and won’t leak any harmful chemicals into our healthy salads. I really like this oil because it’s quick and easy, leaves the wood a vibrant color, and I don’t have to worry about it coming in contact with the things we eat. | ||

|Step_Picture_00=Salad_tongs__tape_5.png | |Step_Picture_00=Salad_tongs__tape_5.png | ||

|Step_Picture_01=Salad_tongs_poncer_logo.png | |Step_Picture_01=Salad_tongs_poncer_logo.png | ||

| Ligne 100 : | Ligne 102 : | ||

|Step_Picture_03=Salad_tongs_beau_logo.png | |Step_Picture_03=Salad_tongs_beau_logo.png | ||

|Step_Picture_04=Salad_tongs_retourn_.png | |Step_Picture_04=Salad_tongs_retourn_.png | ||

| − | |||

| − | |||

}} | }} | ||

| − | {{ | + | {{Tuto Step |

| − | |||

|Step_Title=Now, To Find Some Salad! | |Step_Title=Now, To Find Some Salad! | ||

|Step_Content=This project is done. I set out to make a functional set of salad tongs that we could use for dinner and I did that. But…a project this simple begs for a dash of nerd, so we went a little overboard and made something kind silly (awesome) using more outlandish tools. | |Step_Content=This project is done. I set out to make a functional set of salad tongs that we could use for dinner and I did that. But…a project this simple begs for a dash of nerd, so we went a little overboard and made something kind silly (awesome) using more outlandish tools. | ||

{{Idea|An awesome idea : [http://wikifab.org/wiki/Infinity_Gauntlet_Salad_Tongs| The Infinity Gauntlet Salad Tongs]}} | {{Idea|An awesome idea : [http://wikifab.org/wiki/Infinity_Gauntlet_Salad_Tongs| The Infinity Gauntlet Salad Tongs]}} | ||

| + | |Step_Picture_00=Salad_tongs_der_des_ders.png | ||

}} | }} | ||

| − | {{ | + | {{Notes |

|Notes=Check out this tutoral and many more on [https://www.iliketomakestuff.com/infinity-gauntlet-salad-tongs/ iliketomakestuff.com]. | |Notes=Check out this tutoral and many more on [https://www.iliketomakestuff.com/infinity-gauntlet-salad-tongs/ iliketomakestuff.com]. | ||

}} | }} | ||

| − | {{ | + | {{Tuto Status |

| − | |Complete= | + | |Complete=Published |

}} | }} | ||

Version actuelle datée du 9 décembre 2019 à 11:56

Sommaire

- 1 Introduction

- 2 Video d'introduction

- 3 Étape 1 - Cut down the rough wood

- 4 Étape 2 - Add the slot for the aluminum

- 5 Étape 3 - Shape the wooden handles

- 6 Étape 4 - Drilled out the holes

- 7 Étape 5 - Add the aluminum

- 8 Étape 6 - Drive in the dowels

- 9 Étape 7 - Finish with oil

- 10 Étape 8 - Now, To Find Some Salad!

- 11 Notes et références

- 12 Commentaires

Introduction

Matériaux

Block of basswood

Aluminium bar

Outils

Band saw

Table saw

Belt sander

Drill press

Torch and aluminium rode

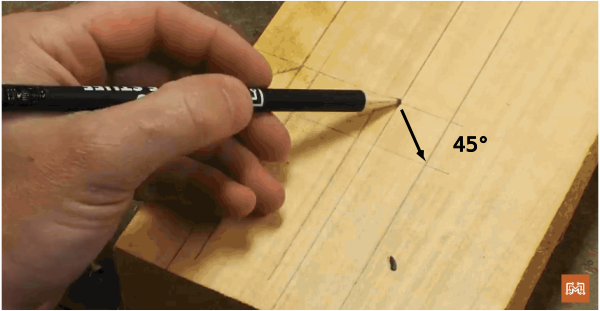

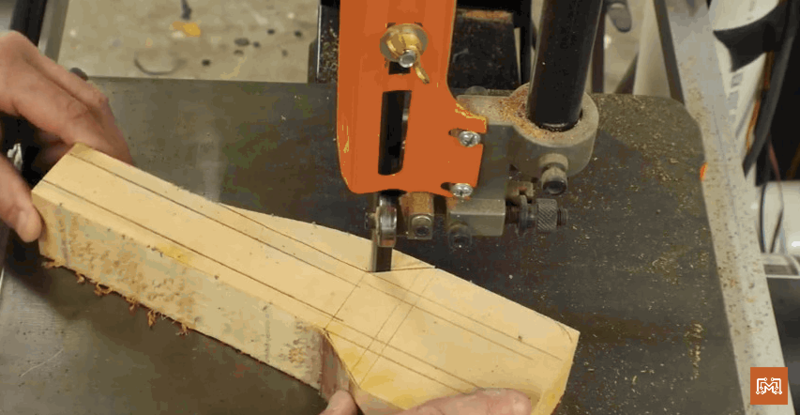

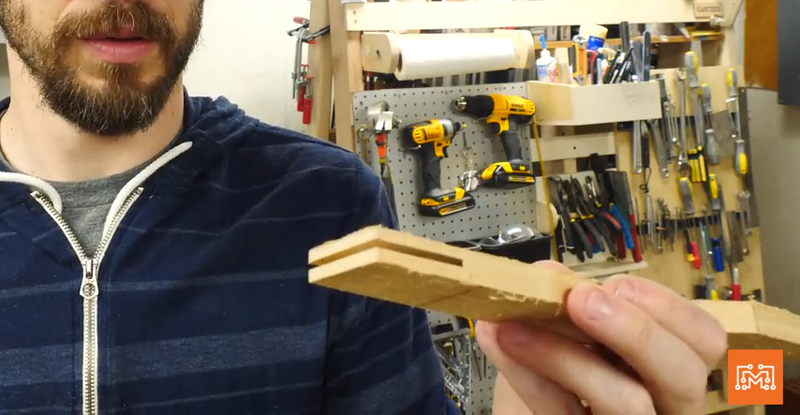

Étape 1 - Cut down the rough wood

For the functional tongs, I use a large chunk of basswood. I drew out the spatula-like shape on the face and cut the thick piece of wood on the band saw. I then turned the piece on its side and resawed the basswood into my two handles. These two halves were still pretty thick and the shape was not yet finalized, all of that would be done with the sanders.

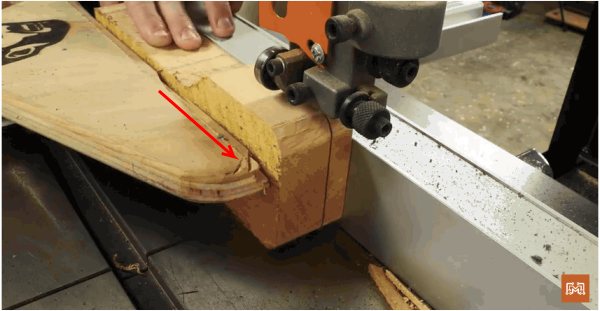

Étape 2 - Add the slot for the aluminum

Now here’s your word of warning, the cut I made into the stem of the handles made me a little nervous. In hindsight, I could have made a quick jig to securely hold the pieces while I passed them over the table saw vertically, but I didn’t think of that at the time. Instead, I mitigated all of the risks and carefully passed the skinny end of the handles over the blade to cut in the pocket that would hold the aluminum.

Étape 3 - Shape the wooden handles

This process involved a lot of patience and a lot of sanding. I flushed up the stem edges with the edges of the aluminum and then used the belt sander to finalize the handles’ overall shape. The two handles were pressed together and sanded simultaneously so that their profiles matched.

The scoop was carved into the paddles by running them over the rounded end of the belt sander. To round over the crisp edges, I clamped the handles to my work bench and used some files to make some comfortable contours.

Étape 4 - Drilled out the holes

For the handles, I used some flat aluminum bar stock that I could bend over to act as a spring. Before I bent the metal, I set the flat bar into the slots on the wooden handles and drilled out the holes for the dowels that would connect the pieces with the drill press. I had some 3/8″ aluminum round bar and cut little dowel pieces on the miter saw. Two holes were drilled through both materials so later, I could permanently peg them together.

Étape 5 - Add the aluminum

To bend the flat bar into a spring, I first scored a groove down the center of the piece to act as a fold line. I carefully heated up the aluminum along this line and hammered the piece over into an acute angle. There was an obvious cut line left in the crease that I wanted to cover up. So, I used a torch and some aluminum rod to braise the crease for some extra strength and to give the handles a cleaner look.

Étape 6 - Drive in the dowels

All that was left was to drive in the dowels through the attachment holes and secure them in place with some glue.

Étape 7 - Finish with oil

Because this piece will be touching food, I used a butcher block conditioner meant for cutting boards. This product is food safe and won’t leak any harmful chemicals into our healthy salads. I really like this oil because it’s quick and easy, leaves the wood a vibrant color, and I don’t have to worry about it coming in contact with the things we eat.

Étape 8 - Now, To Find Some Salad!

This project is done. I set out to make a functional set of salad tongs that we could use for dinner and I did that. But…a project this simple begs for a dash of nerd, so we went a little overboard and made something kind silly (awesome) using more outlandish tools.

Notes et références

Check out this tutoral and many more on iliketomakestuff.com.

Published

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português