(convert properties for internationnalized Wikifab) |

(Cette version a été marquée pour être traduite) |

||

| Ligne 5 : | Ligne 5 : | ||

|Type=Creation | |Type=Creation | ||

|Area=Furniture | |Area=Furniture | ||

| − | |Description=<translate>This DIY standing desk is made from 2x12s and plumbers pipe. The height of the desk can be adjusted by switching out different sections of pipe. You can also watch this Wikifab on [https://www.youtube.com/watch?v=whY_LeFFxgk our video tutorial].</translate> | + | |Description=<translate><!--T:1--> This DIY standing desk is made from 2x12s and plumbers pipe. The height of the desk can be adjusted by switching out different sections of pipe. You can also watch this Wikifab on [https://www.youtube.com/watch?v=whY_LeFFxgk our video tutorial].</translate> |

|Difficulty=Easy | |Difficulty=Easy | ||

|Cost=185 | |Cost=185 | ||

| Ligne 16 : | Ligne 16 : | ||

{{ {{tntn|Introduction}}|}} | {{ {{tntn|Introduction}}|}} | ||

{{ {{tntn|Materials}} | {{ {{tntn|Materials}} | ||

| − | |Material=<translate>* 2"x12"x12' Board (We cut the 12’ board into two 5’6” lengths for our table top.) | + | |Material=<translate><!--T:2--> |

| + | * 2"x12"x12' Board (We cut the 12’ board into two 5’6” lengths for our table top.) | ||

* We used the mending plates to join the two tabletop boards together. | * We used the mending plates to join the two tabletop boards together. | ||

* 3/4" Diameter Black Iron Pipe (see the table) | * 3/4" Diameter Black Iron Pipe (see the table) | ||

| Ligne 29 : | Ligne 30 : | ||

{{Separator}} | {{Separator}} | ||

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

| − | |Step_Title=<translate>Cut the Boards</translate> | + | |Step_Title=<translate><!--T:3--> Cut the Boards</translate> |

| − | |Step_Content=<translate>I cut the boards to the finish length of 5’6” using a speed square to make sure I was getting a perfect right angle cut.</translate> | + | |Step_Content=<translate><!--T:4--> I cut the boards to the finish length of 5’6” using a speed square to make sure I was getting a perfect right angle cut.</translate> |

|Step_Picture_00=Hmm ep74 standingdesk step1a.jpg | |Step_Picture_00=Hmm ep74 standingdesk step1a.jpg | ||

|Step_Picture_01=Hmm ep74 standingdesk step1b.jpg | |Step_Picture_01=Hmm ep74 standingdesk step1b.jpg | ||

}} | }} | ||

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

| − | |Step_Title=<translate>Sand the Edges</translate> | + | |Step_Title=<translate><!--T:5--> Sand the Edges</translate> |

| − | |Step_Content=<translate>Elle sanded all four sides of both boards taking special care to round all the edges and corners.</translate> | + | |Step_Content=<translate><!--T:6--> Elle sanded all four sides of both boards taking special care to round all the edges and corners.</translate> |

|Step_Picture_00=Hmm ep74 standingdesk step2.jpg | |Step_Picture_00=Hmm ep74 standingdesk step2.jpg | ||

}} | }} | ||

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

| − | |Step_Title=<translate>Apply Danish Oil</translate> | + | |Step_Title=<translate><!--T:7--> Apply Danish Oil</translate> |

| − | |Step_Content=<translate>Once all the dust was wiped from the boards, she used a rag to apply one coat of Danish oil.</translate> | + | |Step_Content=<translate><!--T:8--> Once all the dust was wiped from the boards, she used a rag to apply one coat of Danish oil.</translate> |

|Step_Picture_00=Hmm ep74 standingdesk step3.jpg | |Step_Picture_00=Hmm ep74 standingdesk step3.jpg | ||

}} | }} | ||

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

| − | |Step_Title=<translate>Attach the Boards</translate> | + | |Step_Title=<translate><!--T:9--> Attach the Boards</translate> |

| − | |Step_Content=<translate>I attached the two 2”x12” boards together with the mending plates. I centered the plates 4” in from the ends of the boards and then roughly 12” apart leaving about 6” of space between the middle two. Because it's important to keep the two boards as close as possible, I clamped one board to the worktable and had Elle pull the second board into the first as I screwed in the plates.</translate> | + | |Step_Content=<translate><!--T:10--> I attached the two 2”x12” boards together with the mending plates. I centered the plates 4” in from the ends of the boards and then roughly 12” apart leaving about 6” of space between the middle two. Because it's important to keep the two boards as close as possible, I clamped one board to the worktable and had Elle pull the second board into the first as I screwed in the plates.</translate> |

|Step_Picture_00=Hmm ep74 standingdesk step4a.jpg | |Step_Picture_00=Hmm ep74 standingdesk step4a.jpg | ||

|Step_Picture_01=Hmm ep74 standingdesk step4b.jpg | |Step_Picture_01=Hmm ep74 standingdesk step4b.jpg | ||

}} | }} | ||

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

| − | |Step_Title=<translate>Assemble the Legs</translate> | + | |Step_Title=<translate><!--T:11--> Assemble the Legs</translate> |

| − | |Step_Content=<translate>Elle assembled the legs using all the pipes and connectors. Putting them together is easy and fun, but make sure that the end result is straight and screwed together tightly.</translate> | + | |Step_Content=<translate><!--T:12--> Elle assembled the legs using all the pipes and connectors. Putting them together is easy and fun, but make sure that the end result is straight and screwed together tightly.</translate> |

|Step_Picture_00=Hmm ep74 standingdesk step5.jpg | |Step_Picture_00=Hmm ep74 standingdesk step5.jpg | ||

}} | }} | ||

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

| − | |Step_Title=<translate>Screw on the Legs</translate> | + | |Step_Title=<translate><!--T:13--> Screw on the Legs</translate> |

| − | |Step_Content=<translate>We placed the legs on the inside of the outermost plate about 6” in from the ends and 3” in from the sides. It can be a bit difficult to maneuver the drill so close to the pipes, but be sure to drill the screws straight into the wood.</translate> | + | |Step_Content=<translate><!--T:14--> We placed the legs on the inside of the outermost plate about 6” in from the ends and 3” in from the sides. It can be a bit difficult to maneuver the drill so close to the pipes, but be sure to drill the screws straight into the wood.</translate> |

|Step_Picture_00=Hmm ep74 standingdesk step6.jpg | |Step_Picture_00=Hmm ep74 standingdesk step6.jpg | ||

}} | }} | ||

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

| − | |Step_Title=<translate>Adjust the Height</translate> | + | |Step_Title=<translate><!--T:15--> Adjust the Height</translate> |

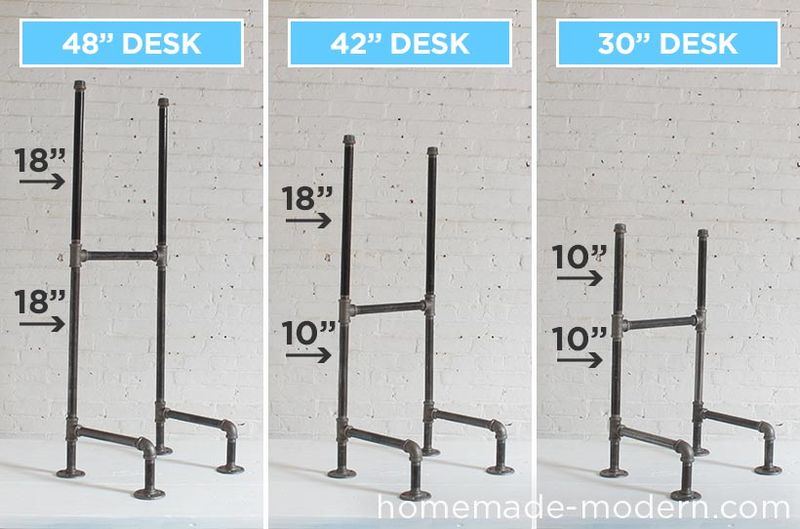

| − | |Step_Content=<translate>The floor of our workshop is a bit uneven, so I adjusted the end caps to level the tables. There are many different options for the height of your desk. We listed the three that we found most useful for our needs. The exact height of the desk will fluctuate a bit depending on how tightly you're able to screw the pipes to the couplings. . | + | |Step_Content=<translate><!--T:16--> |

| + | The floor of our workshop is a bit uneven, so I adjusted the end caps to level the tables. There are many different options for the height of your desk. We listed the three that we found most useful for our needs. The exact height of the desk will fluctuate a bit depending on how tightly you're able to screw the pipes to the couplings. . | ||

| + | <!--T:17--> | ||

Good luck making your own standing desk and please email, tweet or hashtag photos to [https://twitter.com/BenUyeda @benuyeda], ben@homemade-modern.com or #homemademodern. For more detailed instructions, dimensioned drawings and different variations of the project, check out our soon-to-be-released book.</translate> | Good luck making your own standing desk and please email, tweet or hashtag photos to [https://twitter.com/BenUyeda @benuyeda], ben@homemade-modern.com or #homemademodern. For more detailed instructions, dimensioned drawings and different variations of the project, check out our soon-to-be-released book.</translate> | ||

|Step_Picture_00=Hmm ep74 standingdesk step7.jpg | |Step_Picture_00=Hmm ep74 standingdesk step7.jpg | ||

| Ligne 72 : | Ligne 75 : | ||

}} | }} | ||

{{ {{tntn|Notes}} | {{ {{tntn|Notes}} | ||

| − | |Notes=<translate>* This project is also available [http://homemade-modern.com/ep74-standing-desk/ on my blog] | + | |Notes=<translate><!--T:18--> |

| + | * This project is also available [http://homemade-modern.com/ep74-standing-desk/ on my blog] | ||

* Watch the video tutorial of this standing desk on [https://www.youtube.com/watch?v=whY_LeFFxgk my Youtube channel] | * Watch the video tutorial of this standing desk on [https://www.youtube.com/watch?v=whY_LeFFxgk my Youtube channel] | ||

}} | }} | ||

Version du 11 août 2017 à 13:24

Matériaux

- 2"x12"x12' Board (We cut the 12’ board into two 5’6” lengths for our table top.)

- We used the mending plates to join the two tabletop boards together.

- 3/4" Diameter Black Iron Pipe (see the table)

- 3/4" Black Iron Couplings (see the table)

- 1/4" Black Drywall Screws (We used the screws to attach the mending plates and the legs.)

Outils

- Cordless Drill

- Circular Saw

- Orbital Sander

Étape 1 - Cut the Boards

I cut the boards to the finish length of 5’6” using a speed square to make sure I was getting a perfect right angle cut.

Étape 2 - Sand the Edges

Elle sanded all four sides of both boards taking special care to round all the edges and corners.

Étape 3 - Apply Danish Oil

Once all the dust was wiped from the boards, she used a rag to apply one coat of Danish oil.

Étape 4 - Attach the Boards

I attached the two 2”x12” boards together with the mending plates. I centered the plates 4” in from the ends of the boards and then roughly 12” apart leaving about 6” of space between the middle two. Because it's important to keep the two boards as close as possible, I clamped one board to the worktable and had Elle pull the second board into the first as I screwed in the plates.

Étape 5 - Assemble the Legs

Elle assembled the legs using all the pipes and connectors. Putting them together is easy and fun, but make sure that the end result is straight and screwed together tightly.

Étape 6 - Screw on the Legs

We placed the legs on the inside of the outermost plate about 6” in from the ends and 3” in from the sides. It can be a bit difficult to maneuver the drill so close to the pipes, but be sure to drill the screws straight into the wood.

Étape 7 - Adjust the Height

The floor of our workshop is a bit uneven, so I adjusted the end caps to level the tables. There are many different options for the height of your desk. We listed the three that we found most useful for our needs. The exact height of the desk will fluctuate a bit depending on how tightly you're able to screw the pipes to the couplings. .

Good luck making your own standing desk and please email, tweet or hashtag photos to @benuyeda, ben@homemade-modern.com or #homemademodern. For more detailed instructions, dimensioned drawings and different variations of the project, check out our soon-to-be-released book.

Notes et références

- This project is also available on my blog

- Watch the video tutorial of this standing desk on my Youtube channel

Yes

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português