| (25 révisions intermédiaires par 3 utilisateurs non affichées) | |||

| Ligne 1 : | Ligne 1 : | ||

| − | {{ | + | {{Tuto Details |

| − | |Main_Picture=Montaje_de_P3steel_por_HTA3D_-_Tutorial_9_- | + | |Main_Picture=Montaje_de_P3steel_por_HTA3D_-_Tutorial_9_-_Calibrar_desfase_de_las_boquillas_para_Dual_3.jpg |

| − | | | + | |Description=<translate><!--T:1--> |

| − | + | Montaje de P3steel por HTA3D - Tutorial 9 - Calibrar desfase de las boquillas</translate> | |

|Area=Electronics, Machines and Tools | |Area=Electronics, Machines and Tools | ||

|Type=Technique | |Type=Technique | ||

| Ligne 14 : | Ligne 14 : | ||

|IsTranslation=0 | |IsTranslation=0 | ||

}} | }} | ||

| − | {{ | + | {{Introduction |

| − | |Introduction=En este tutorial vamos a calibrar el desfase entre las boquillas en los ejes X e Y de nuestra impresora P3Steel Dual. | + | |Introduction=<translate><!--T:2--> |

| + | En este tutorial vamos a calibrar el desfase entre las boquillas en los ejes X e Y de nuestra impresora P3Steel Dual. | ||

| + | <!--T:3--> | ||

Pieza para calibrar desfases entre boquillas (descargada de thingiverse, editada por nosotros) : | Pieza para calibrar desfases entre boquillas (descargada de thingiverse, editada por nosotros) : | ||

| − | Thingiverse (original): [https://www.youtube.com/redirect?redir_token=v12L2s7KZACHYUh304Do6jp9eT58MTU0NzY1MjMxM0AxNTQ3NTY1OTEz&q=http%3A%2F%2Fwww.thingiverse.com%2Fthing%3A1526735&v=27SIeoq8rmI&event=video_description http://www.thingiverse.com/thing:1526735] | + | <!--T:4--> |

| + | Thingiverse (original): [https://www.youtube.com/redirect?redir_token=v12L2s7KZACHYUh304Do6jp9eT58MTU0NzY1MjMxM0AxNTQ3NTY1OTEz&q=http%3A%2F%2Fwww.thingiverse.com%2Fthing%3A1526735&v=27SIeoq8rmI&event=video_description http://www.thingiverse.com/thing:1526735] | ||

| − | Archivos stl editados/Edited stl files: | + | <!--T:5--> |

| + | Archivos stl editados/Edited stl files: http://www.mediafire.com/file/tdxckgyquuwu344/SUB+MILLIMETER+CALIBRATION+STL.rar | ||

| − | Gcode (ABS, nozzle 0.4mm): | + | <!--T:6--> |

| + | Gcode (ABS, nozzle 0.4mm): https://www.mediafire.com/file/abxozon7zd9jlxz/ABS+sub_millimeter_calibration.gcode | ||

| − | Gcode (PLA, nozzle 0.4mm): | + | <!--T:7--> |

| + | Gcode (PLA, nozzle 0.4mm): https://www.mediafire.com/file/yzaq69c0q8c8lge/PLA+sub_millimeter_calibration.gcode | ||

| − | (códigos recomendados sólo para nuestra impresora dual/gcodes only recommended for our Dual 3D printer) | + | <!--T:8--> |

| + | (códigos recomendados sólo para nuestra impresora dual/gcodes only recommended for our Dual 3D printer) | ||

| + | <!--T:9--> | ||

[https://wikifab.org/w/index.php?title=Www.hta3d.com&action=edit&redlink=1 www.hta3d.com] | [https://wikifab.org/w/index.php?title=Www.hta3d.com&action=edit&redlink=1 www.hta3d.com] | ||

| − | https://www.hta3d.com/es/kit-p3steel-dual | + | <!--T:10--> |

| + | https://www.hta3d.com/es/kit-p3steel-dual</translate> | ||

}} | }} | ||

| − | {{ | + | {{Materials |

|Step_Picture_00=Montaje_de_P3steel_por_HTA3D_-_Tutorial_8_-_Calibración_del_Flujo_del_Hotend_aviso_peligro_5_5-4.jpg | |Step_Picture_00=Montaje_de_P3steel_por_HTA3D_-_Tutorial_8_-_Calibración_del_Flujo_del_Hotend_aviso_peligro_5_5-4.jpg | ||

| − | |Material= | + | |Material=<translate></translate> |

| − | |Tools= | + | |Tools=<translate></translate> |

}} | }} | ||

| − | {{ {{ | + | {{Tuto Step |

| − | {{ {{ | + | |Step_Title=<translate><!--T:11--> |

| − | |Step_Title= | + | Impresión de Pieza de Calibración</translate> |

| − | |Step_Content= | + | |Step_Content=<translate><!--T:12--> |

| + | Para calibrar la separación de las boquillas de una forma precisa, tendremos que tener en cuenta los valores de desfase iniciales de la segunda boquilla respecto a la primera en X e Y, siendo de 18mm en X y 0mm en Y, que son los valores que cargamos por defecto en el firmware. | ||

| + | |||

| + | <!--T:13--> | ||

| + | Imprimimos esta pieza impresa (descargada de thingiverse.com, enlaces en Introducción), que nos ayudará a ajustar el desfase en cada uno de los ejes. | ||

| + | |||

| + | <!--T:14--> | ||

| + | {{Idea|Si se realiza tras el cambio de una boquilla o alguna modificación en el hotend, hay que tomar como referencia los últimos valores asignados y no los iniciales. }}</translate> | ||

| + | |Step_Picture_00=Montaje_de_P3steel_por_HTA3D_-_Tutorial_9_-_Calibrar_desfase_de_las_boquillas_para_Dual_7.jpg | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate><!--T:15--> | ||

| + | Indicadores de calibración</translate> | ||

| + | |Step_Content=<translate><!--T:16--> | ||

| + | Una vez al tengamos impresa, comprobamos que: | ||

| + | #Las dos líneas más largas del eje X coincidan. | ||

| + | #Las dos líneas más largas del eje Y coincidan. | ||

| + | Además, encontramos otros indicadores de calibración en: | ||

| + | *Cubo: En el caso de que la segunda boquilla no esté nivelada en altura respecto a la primera encontraríamos desfases o solapamientos en las líneas horizontales de unión de ambos colores. En las verticales podemos ver el desfase en X e Y. | ||

| + | *Cuadrados concéntricos: desfases en X e Y.</translate> | ||

| + | |Step_Picture_00=Montaje_de_P3steel_por_HTA3D_-_Tutorial_9_-_Calibrar_desfase_de_las_boquillas_para_Dual_8.jpg | ||

| + | |Step_Picture_00_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":800,"height":582,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.75,"scaleY":0.75,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://wikifab.org/images/thumb/d/d2/Montaje_de_P3steel_por_HTA3D_-_Tutorial_9_-_Calibrar_desfase_de_las_boquillas_para_Dual_8.jpg/800px-Montaje_de_P3steel_por_HTA3D_-_Tutorial_9_-_Calibrar_desfase_de_las_boquillas_para_Dual_8.jpg","filters":[]},{"type":"wfarrow2line","version":"2.4.6","originX":"center","originY":"center","left":193.5,"top":114,"width":77,"height":6,"fill":"rgba(255,0,0,0)","stroke":"red","strokeWidth":3,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":-38.5,"x2":38.5,"y1":-3,"y2":3,"x2a":19.1819360623254,"y2a":-6.529554328504361,"x2b":17.93895071512918,"y2b":9.422090960513808},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":155,"top":111,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":232,"top":117,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2line","version":"2.4.6","originX":"center","originY":"center","left":194,"top":147,"width":78,"height":6,"fill":"rgba(255,0,0,0)","stroke":"red","strokeWidth":3,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":-39,"x2":39,"y1":-3,"y2":3,"x2a":19.672482281046264,"y2a":-6.510365861707394,"x2b":18.44533829889047,"y2b":9.442505906317912},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":155,"top":144,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":233,"top":150,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfcircle","version":"2.4.6","originX":"center","originY":"center","left":453.37,"top":142.37,"width":200,"height":200,"fill":"rgba(255,0,0,0)","stroke":"red","strokeWidth":8.57,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.35,"scaleY":0.35,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":100,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfrect","version":"2.4.6","originX":"center","originY":"center","left":209,"top":385,"width":100,"height":100,"fill":"rgba(255,0,0,0)","stroke":"red","strokeWidth":2,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"rx":0,"ry":0}],"height":436,"width":600} | ||

| + | |Step_Picture_01=Montaje_de_P3steel_por_HTA3D_-_Tutorial_9_-_Calibrar_desfase_de_las_boquillas_para_Dual_10.jpg | ||

| + | |Step_Picture_01_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":800,"height":582,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.75,"scaleY":0.75,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://wikifab.org/images/thumb/2/22/Montaje_de_P3steel_por_HTA3D_-_Tutorial_9_-_Calibrar_desfase_de_las_boquillas_para_Dual_10.jpg/800px-Montaje_de_P3steel_por_HTA3D_-_Tutorial_9_-_Calibrar_desfase_de_las_boquillas_para_Dual_10.jpg","filters":[]},{"type":"textbox","version":"2.4.6","originX":"center","originY":"center","left":369.89,"top":288.76,"width":47.8,"height":22.6,"fill":"red","stroke":"red","strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":3.95,"scaleY":3.95,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"text":"Y","fontSize":20,"fontWeight":"normal","fontFamily":"sans-serif","fontStyle":"normal","lineHeight":1.16,"underline":false,"overline":false,"linethrough":false,"textAlign":"left","textBackgroundColor":"","charSpacing":0,"minWidth":20,"styles":{} },{"type":"wfarrow2line","version":"2.4.6","originX":"center","originY":"center","left":126.5,"top":296.5,"width":3,"height":71,"fill":"rgba(255,0,0,0)","stroke":"red","strokeWidth":3,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":-1.5,"x2":1.5,"y1":35.5,"y2":-35.5,"x2a":8.648551054459766,"y2a":-15.18010290818917,"x2b":-7.337185161812467,"y2b":-15.855556551130249},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":125,"top":332,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":128,"top":261,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfcircle","version":"2.4.6","originX":"center","originY":"center","left":156.85,"top":53.85,"width":200,"height":200,"fill":"rgba(255,0,0,0)","stroke":"red","strokeWidth":8.82,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.34,"scaleY":0.34,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":100,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfrect","version":"2.4.6","originX":"center","originY":"center","left":298,"top":290,"width":100,"height":100,"fill":"rgba(255,0,0,0)","stroke":"red","strokeWidth":2,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"rx":0,"ry":0},{"type":"wfarrow2line","version":"2.4.6","originX":"center","originY":"center","left":160,"top":297.5,"width":2,"height":71,"fill":"rgba(255,0,0,0)","stroke":"red","strokeWidth":3,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":-1,"x2":1,"y1":35.5,"y2":-35.5,"x2a":8.433671018860746,"y2a":-15.282667456280244,"x2b":-7.559984809597222,"y2b":-15.733192972574834},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":159,"top":333,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":161,"top":262,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586}],"height":436,"width":600} | ||

| + | |Step_Picture_02=Montaje_de_P3steel_por_HTA3D_-_Tutorial_9_-_Calibrar_desfase_de_las_boquillas_para_Dual_12.jpg | ||

| + | |Step_Picture_02_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":800,"height":582,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.75,"scaleY":0.75,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://wikifab.org/images/thumb/c/cd/Montaje_de_P3steel_por_HTA3D_-_Tutorial_9_-_Calibrar_desfase_de_las_boquillas_para_Dual_12.jpg/800px-Montaje_de_P3steel_por_HTA3D_-_Tutorial_9_-_Calibrar_desfase_de_las_boquillas_para_Dual_12.jpg","filters":[]},{"type":"wfarrow2line","version":"2.4.6","originX":"center","originY":"center","left":168.5,"top":197.5,"width":81,"height":1,"fill":"rgba(255,0,0,0)","stroke":"red","strokeWidth":3,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":-40.5,"x2":40.5,"y1":-0.5,"y2":0.5,"x2a":20.600281889948942,"y2a":-7.7462851721551536,"x2b":20.402766077442234,"y2b":8.252495640888379},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":128,"top":197,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":209,"top":198,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2line","version":"2.4.6","originX":"center","originY":"center","left":460.5,"top":171.5,"width":109,"height":19,"fill":"rgba(255,0,0,0)","stroke":"red","strokeWidth":3,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":54.5,"x2":-54.5,"y1":-9.5,"y2":9.5,"x2a":-33.42331239655341,"y2a":13.946711106730582,"x2b":-36.170873730793446,"y2b":-1.81561444233067},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":515,"top":162,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":406,"top":181,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586}],"height":436,"width":600} | ||

| + | |Step_Picture_03=Montaje_de_P3steel_por_HTA3D_-_Tutorial_9_-_Calibrar_desfase_de_las_boquillas_para_Dual_13a.jpg | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate><!--T:17--> | ||

| + | Desfase en el eje X</translate> | ||

| + | |Step_Content=<translate><!--T:18--> | ||

| + | En el eje X vemos la línea que coincide mejor es la que encontramos inmediatamente a la derecha de las líneas de referencia. | ||

| + | |||

| + | <!--T:19--> | ||

| + | Cada línea representa 0.1 mm de desfase. Al encontrarse hacia la derecha significa que el filamento verde está desfasado hacia la izquierda. Lo que implica que está situado a -0.1mm de desfase respecto a lo indicado en el firmware.</translate> | ||

| + | |Step_Picture_00=Montaje_de_P3steel_por_HTA3D_-_Tutorial_9s.jpg | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate><!--T:20--> | ||

| + | Desfase en el eje Y</translate> | ||

| + | |Step_Content=<translate><!--T:21--> | ||

| + | En el eje Y vemos la línea que coincide mejor se encuentra también justo a la derecha las líneas de referencia. | ||

| + | |||

| + | <!--T:22--> | ||

| + | Al igual que en el eje X, significa que tiene un desfase de -0.1mm.</translate> | ||

| + | |Step_Picture_00=Montaje_de_P3steel_por_HTA3D_-_Tutorial_9_-_Calibrar_desfase_de_las_boquillas_para_Dual_22.jpg | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate><!--T:23--> | ||

| + | Código de corrección</translate> | ||

| + | |Step_Content=<translate><!--T:24--> | ||

| + | Una vez identificado el desfase vamos a transmitirlo a la impresora para corregirlo. | ||

| + | |||

| + | <!--T:25--> | ||

| + | Lo haremos a través de un código de impresión, en el que añadiremos un par de líneas que ajustará los parámetros que hemos calculado. | ||

| + | |||

| + | <!--T:26--> | ||

| + | Gcode (ABS, nozzle 0.4mm): https://www.mediafire.com/file/abxozon7zd9jlxz/ABS+sub_millimeter_calibration.gcode | ||

| + | |||

| + | <!--T:27--> | ||

| + | Gcode (PLA, nozzle 0.4mm): https://www.mediafire.com/file/yzaq69c0q8c8lge/PLA+sub_millimeter_calibration.gcode | ||

| + | |||

| + | <!--T:28--> | ||

| + | En las primeras líneas del código se ha añadido la configuración de desfase de las boquillas cargada en el firmware, que nos servirá como base.</translate> | ||

| + | |Step_Picture_00=Montaje_de_P3steel_por_HTA3D_-_Tutorial_9_-_Calibrar_desfase_de_las_boquillas_para_Dual_23.jpg | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate><!--T:29--> | ||

| + | Aplicación de la calibración al código</translate> | ||

| + | |Step_Content=<translate><!--T:30--> | ||

| + | Ahora vamos a actualizarlo con los valores obtenidos y habilitar las líneas. | ||

| + | |||

| + | <!--T:31--> | ||

| + | La primera instrucción G10 hace referencia a la posición de la boquilla 1, que no debemos modificar. | ||

| + | |||

| + | <!--T:32--> | ||

| + | La segunda instrucción G10 hace referencia a la posición de la boquilla 2, y es donde aplicaremos los resultados. | ||

| + | |||

| + | <!--T:33--> | ||

| + | En este caso hemos obtenido -0.1mm en X y -0.1mm en Y. Así que los valores resultantes son 17.9 en X y -0.1 en Y. | ||

| + | |||

| + | <!--T:34--> | ||

| + | El comando M500 nos guardará la configuración en la memoria. Para habilitar los códigos sólo hay que borrar cada “;” de las líneas. | ||

| + | |||

| + | <!--T:35--> | ||

| + | Imprimimos de nuevo la pieza de calibración. | ||

| + | |||

| + | <!--T:36--> | ||

| + | {{Info|Este ajuste lo podemos hacer también cargando de nuevo el firmware actualizado o conectando la impresora por USB. Pero consideremos esta la forma más práctica, y aprovechamos que es recomendable volver a imprimir para comprobar que la calibración ha sido realizada correctamente.}}</translate> | ||

| + | |Step_Picture_00=Montaje_de_P3steel_por_HTA3D_-_Tutorial_9_-_Calibrar_desfase_de_las_boquillas_para_Dual_25.jpg | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate><!--T:37--> | ||

| + | Calibración correcta</translate> | ||

| + | |Step_Content=<translate><!--T:38--> | ||

| + | En el caso de que hubiese algún desfase podemos repetirlo tantas veces como sea necesario.</translate> | ||

| + | |Step_Picture_00=Montaje_de_P3steel_por_HTA3D_-_Tutorial_9_-_Calibrar_desfase_de_las_boquillas_para_Dual_26.jpg | ||

| + | |Step_Picture_00_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":800,"height":581,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.75,"scaleY":0.75,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://wikifab.org/images/thumb/6/64/Montaje_de_P3steel_por_HTA3D_-_Tutorial_9_-_Calibrar_desfase_de_las_boquillas_para_Dual_26.jpg/800px-Montaje_de_P3steel_por_HTA3D_-_Tutorial_9_-_Calibrar_desfase_de_las_boquillas_para_Dual_26.jpg","filters":[]}],"height":436,"width":600} | ||

| + | }} | ||

| + | {{Notes | ||

| + | |Notes=<translate></translate> | ||

}} | }} | ||

| − | {{ | + | {{PageLang |

| − | |||

}} | }} | ||

| − | {{ | + | {{Tuto Status |

| − | |Complete= | + | |Complete=Published |

}} | }} | ||

| + | {{Separator}} | ||

Version actuelle datée du 2 janvier 2020 à 17:50

Sommaire

Introduction

En este tutorial vamos a calibrar el desfase entre las boquillas en los ejes X e Y de nuestra impresora P3Steel Dual.

Pieza para calibrar desfases entre boquillas (descargada de thingiverse, editada por nosotros) :

Thingiverse (original): http://www.thingiverse.com/thing:1526735

Archivos stl editados/Edited stl files: http://www.mediafire.com/file/tdxckgyquuwu344/SUB+MILLIMETER+CALIBRATION+STL.rar

Gcode (ABS, nozzle 0.4mm): https://www.mediafire.com/file/abxozon7zd9jlxz/ABS+sub_millimeter_calibration.gcode

Gcode (PLA, nozzle 0.4mm): https://www.mediafire.com/file/yzaq69c0q8c8lge/PLA+sub_millimeter_calibration.gcode

(códigos recomendados sólo para nuestra impresora dual/gcodes only recommended for our Dual 3D printer)

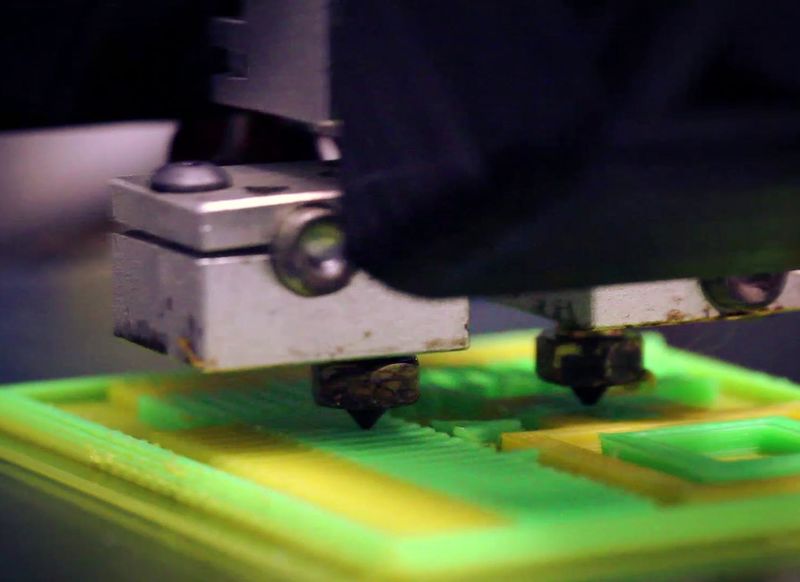

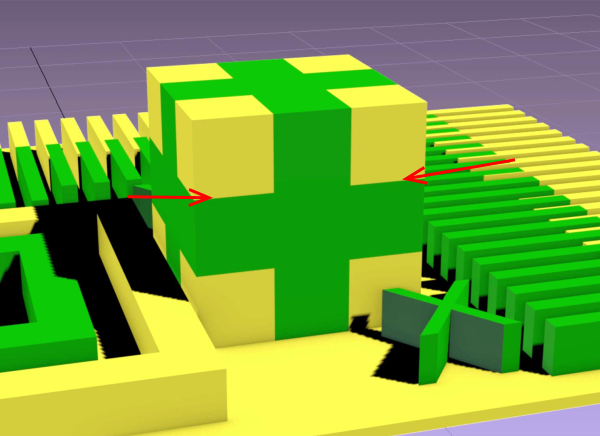

https://www.hta3d.com/es/kit-p3steel-dualÉtape 1 - Impresión de Pieza de Calibración

Para calibrar la separación de las boquillas de una forma precisa, tendremos que tener en cuenta los valores de desfase iniciales de la segunda boquilla respecto a la primera en X e Y, siendo de 18mm en X y 0mm en Y, que son los valores que cargamos por defecto en el firmware.

Imprimimos esta pieza impresa (descargada de thingiverse.com, enlaces en Introducción), que nos ayudará a ajustar el desfase en cada uno de los ejes.

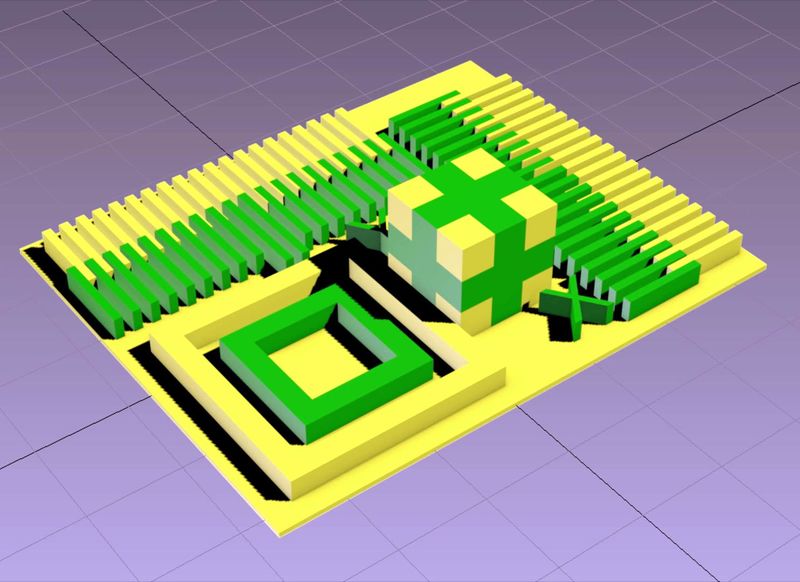

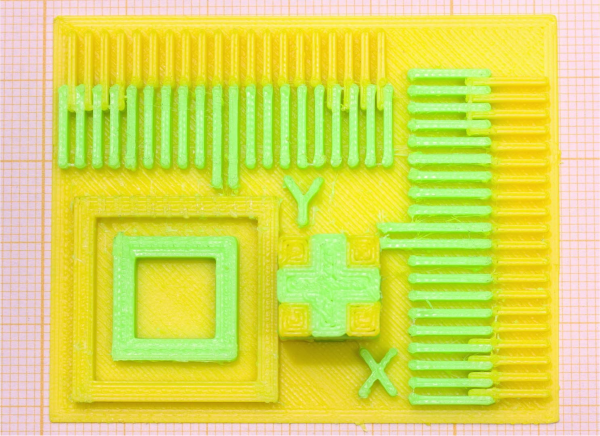

Étape 2 - Indicadores de calibración

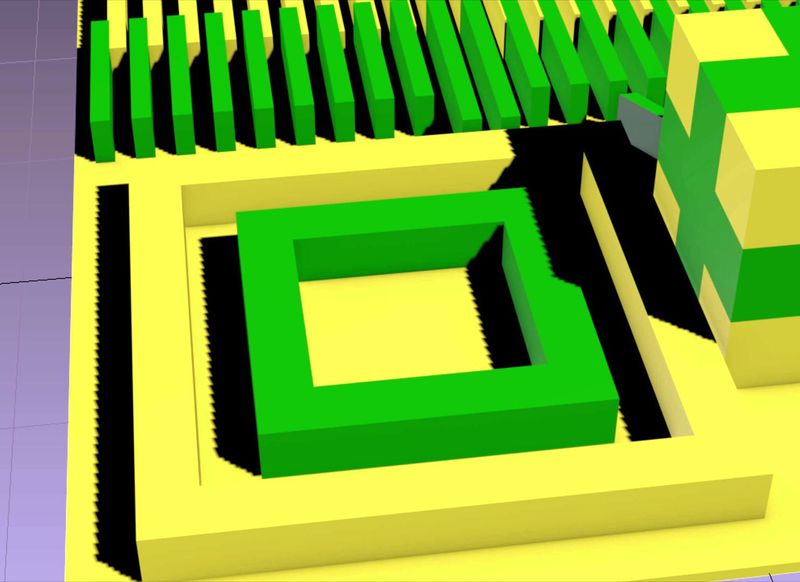

Una vez al tengamos impresa, comprobamos que:

- Las dos líneas más largas del eje X coincidan.

- Las dos líneas más largas del eje Y coincidan.

Además, encontramos otros indicadores de calibración en:

- Cubo: En el caso de que la segunda boquilla no esté nivelada en altura respecto a la primera encontraríamos desfases o solapamientos en las líneas horizontales de unión de ambos colores. En las verticales podemos ver el desfase en X e Y.

- Cuadrados concéntricos: desfases en X e Y.

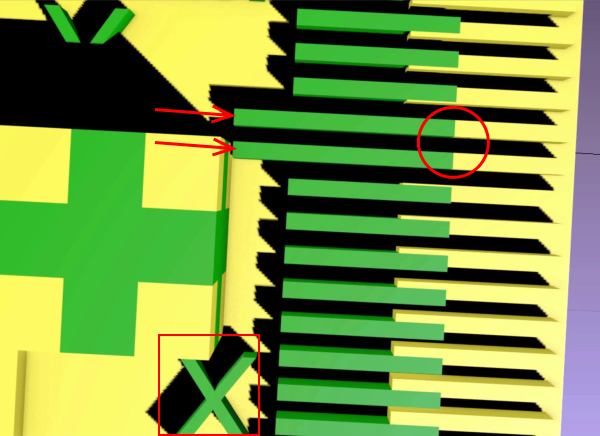

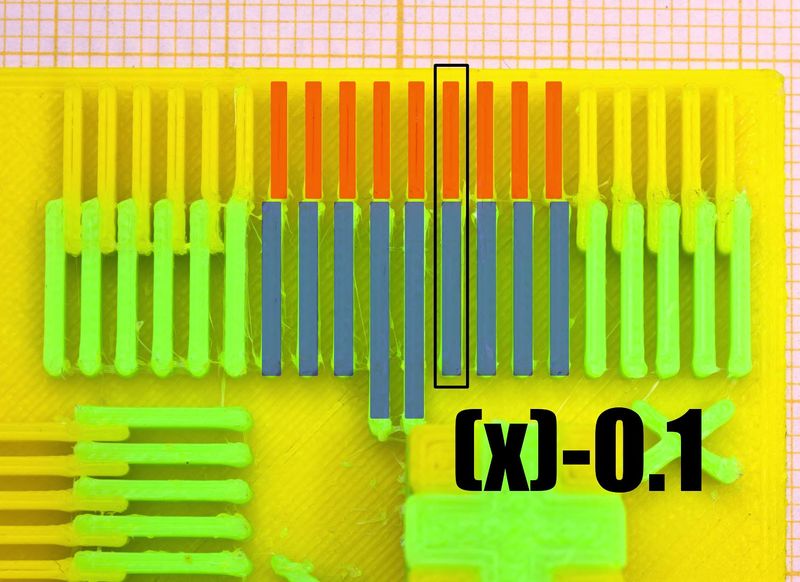

Étape 3 - Desfase en el eje X

En el eje X vemos la línea que coincide mejor es la que encontramos inmediatamente a la derecha de las líneas de referencia.

Cada línea representa 0.1 mm de desfase. Al encontrarse hacia la derecha significa que el filamento verde está desfasado hacia la izquierda. Lo que implica que está situado a -0.1mm de desfase respecto a lo indicado en el firmware.

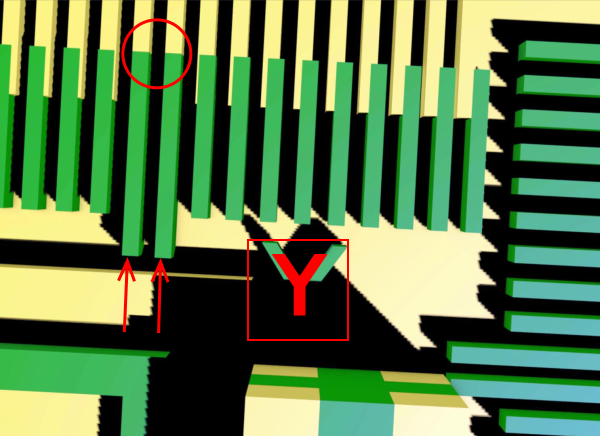

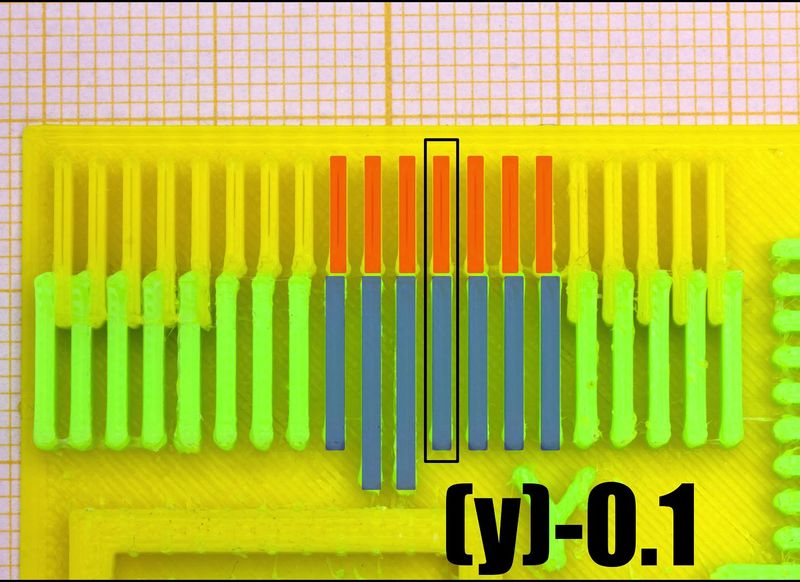

Étape 4 - Desfase en el eje Y

En el eje Y vemos la línea que coincide mejor se encuentra también justo a la derecha las líneas de referencia.

Al igual que en el eje X, significa que tiene un desfase de -0.1mm.

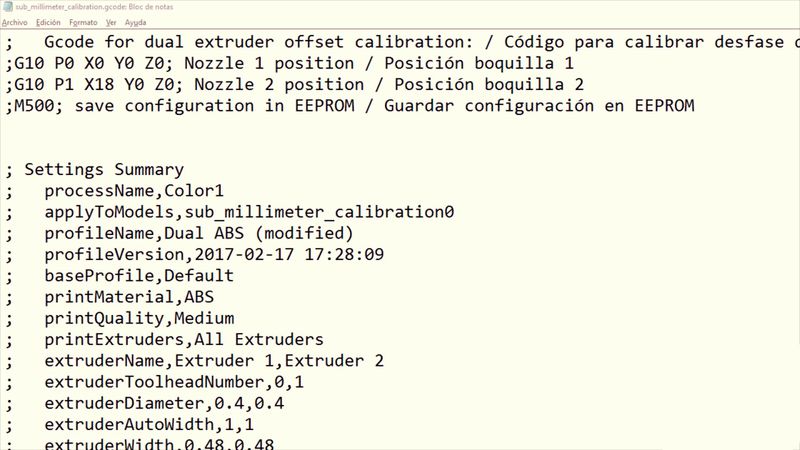

Étape 5 - Código de corrección

Una vez identificado el desfase vamos a transmitirlo a la impresora para corregirlo.

Lo haremos a través de un código de impresión, en el que añadiremos un par de líneas que ajustará los parámetros que hemos calculado.

Gcode (ABS, nozzle 0.4mm): https://www.mediafire.com/file/abxozon7zd9jlxz/ABS+sub_millimeter_calibration.gcode

Gcode (PLA, nozzle 0.4mm): https://www.mediafire.com/file/yzaq69c0q8c8lge/PLA+sub_millimeter_calibration.gcode

En las primeras líneas del código se ha añadido la configuración de desfase de las boquillas cargada en el firmware, que nos servirá como base.

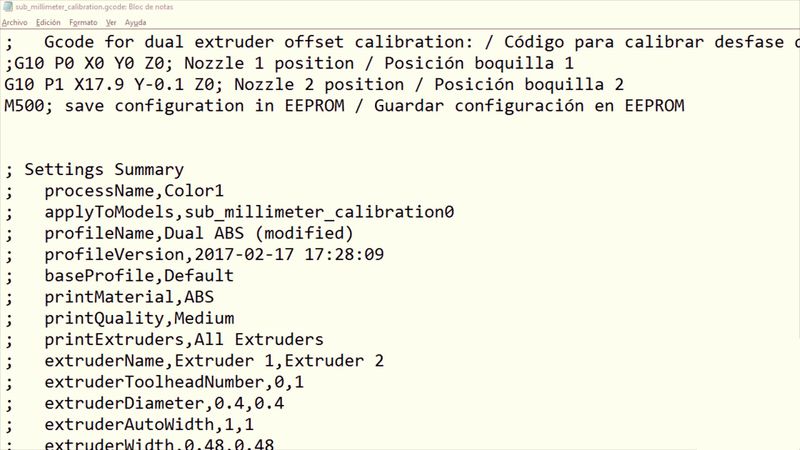

Étape 6 - Aplicación de la calibración al código

Ahora vamos a actualizarlo con los valores obtenidos y habilitar las líneas.

La primera instrucción G10 hace referencia a la posición de la boquilla 1, que no debemos modificar.

La segunda instrucción G10 hace referencia a la posición de la boquilla 2, y es donde aplicaremos los resultados.

En este caso hemos obtenido -0.1mm en X y -0.1mm en Y. Así que los valores resultantes son 17.9 en X y -0.1 en Y.

El comando M500 nos guardará la configuración en la memoria. Para habilitar los códigos sólo hay que borrar cada “;” de las líneas.

Imprimimos de nuevo la pieza de calibración.

Étape 7 - Calibración correcta

En el caso de que hubiese algún desfase podemos repetirlo tantas veces como sea necesario.

Published

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português