There are 3 chapters,

The bike stand The electric conversion The energy moitoringTo find out more about the Vélo M² project and other project, visit www.velom2.be.

Introduction

Matériaux

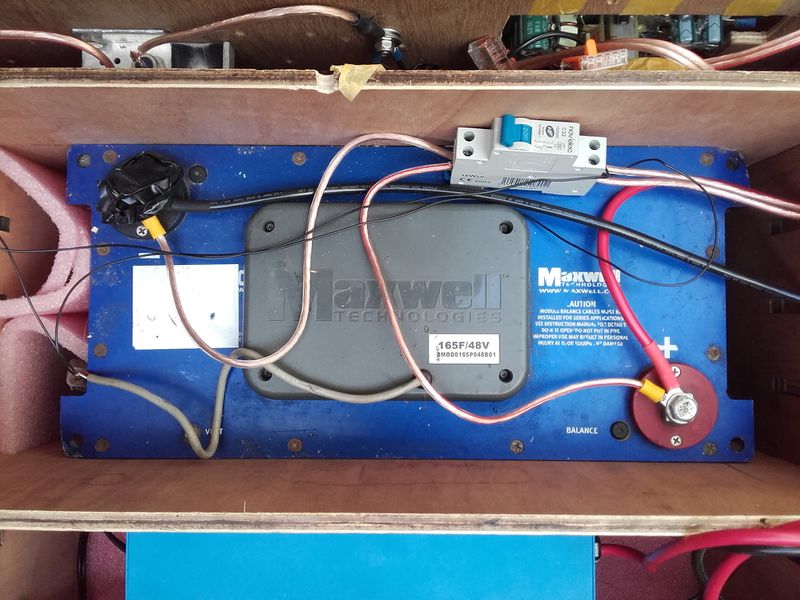

- Supercapacitor (here 165F 48V)

- Inverter (here 800VA)

- Electric connections, switched and wires

- DC/DC converter

Outils

- Soldering iron

Étape 1 - Overview of the system

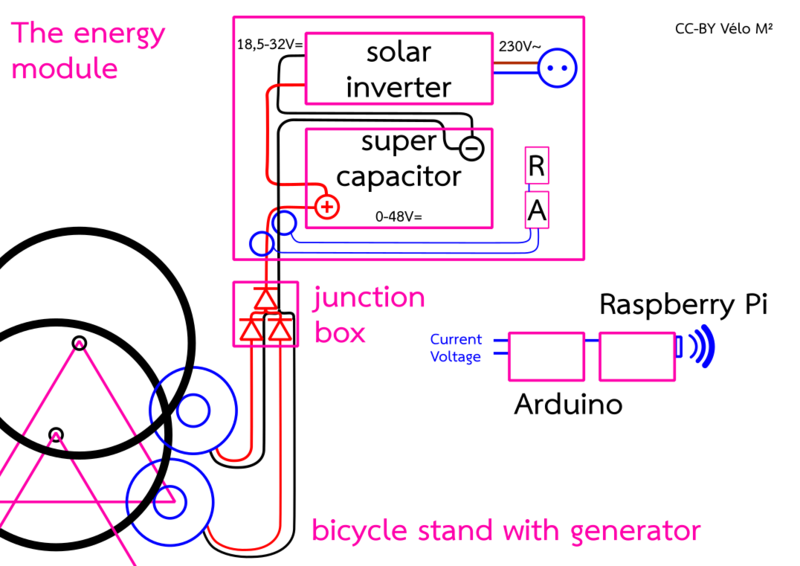

In words, we are harvesting the energy from stationary bikes. The energy is converted to regular AC power. We also monitor the energy flow wit the Open Energy Monitoring system. The bike stands we designed fit regular bikes. The bike wheel drives an electric motor with converts the mechanical energy into electric energy. The DC power is conducted through a diode and through a current sensor. Then the different cables are connected to the supercapacitor. This is the common point. From the supercapacitor we draw the power for the solar inverter that converts the fluctuating DC power to regular AC power. We monitor the power before the common point. An Arduino takes in the values of the current and voltage and transfers it to a Raspberry Pi that logs the data. An app on the smartphone allows to visualize the data.

Étape 2 - Chose your buffer

You can chose between different buffering systems, an battery, a supercapacitor or a flywheel.

We chose a supercapacitor. A supercapacitor is an electronic component able to hold a charge. It can be used in the same function as batteries with the following differences :

+ a capacitor is easier to recycle than most batteries (references will follow).

+ a capacitor can provide and absorb a higher peak power.

– the voltage varies with the charging state of the capacitor (it needs an additional converter to provide the voltage of the system)

– the energy by weight capacity is less interesting than with batteries.

– the cost by energy is higher.

– the lifetime is quasi infinite (1M cycles).

The energy storage of a supercapacitor :

energy = 1/2 * C * voltage difference^2

http://www.engineeringtoolbox.com/capacitors-energy-power-d_1389.html

ex = 1/2 * 500F * (16-12)^2 = 4000J = 1.11Wh = 1 cyclist for 1min20sec

http://www.maxwell.com/products/ultracapacitors/16v-large-modules/documents

Étape 3 - (if you chose a battery)

First remark : if you can avoid using a battery and work with the people pedal power in stead, this is considerably more interesting for the environment

– car batteries a heavy compared with the energy they can store, they are designed for giving high current.

– deep cycle / cyclic / boat batteries can contain more energy because of the internal structure of the battery technology, allowing a deep discharge.

*input* : user power (ex sound system of 900W peak)

*input* : time of autonomy (ex one hour before charging)

*input* : voltage of the system (ex 12V)

*energy need* = user power * time of autonomy (ex = 900Wh for the sound system)

checking the battery parameters

– Gel and Absorbent Glass Mat (AGM) types of VRLA can be mounted in any orientation, but need to be ventilated.

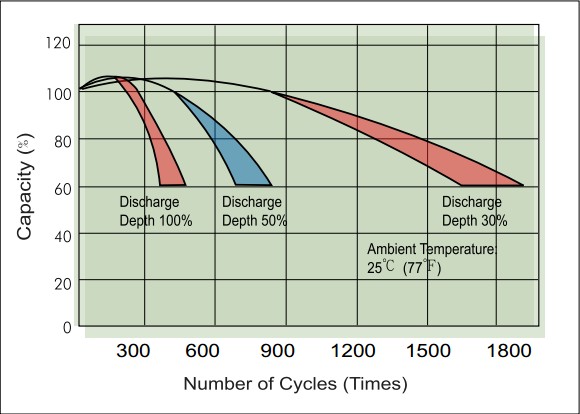

– the depth of discharge (DOD) of a battery determines the capacity and the number of cycles, 60% is a good value for AGM batteries (check DOD documentation).

– the current of discharging lowers the voltage output, the higher the discharge current, the lower the voltage and the lower the capacity.

*battery voltage at the DOD* > voltage of the system (ex 6 cel Li-ion doesn’t work, ex when discharging in 3h (0,3C), after 3h the battery voltage drops to 11V)

*charge need* (Ah) = energy need / voltage / depth of discharge (ex = 900Wh / 12V / 60% = 125Ah)

ex DAB12-135EV 12V 166Ah 136Ah 342 173 286 B M8 43,3 http://www.dynoeurope.com/assets/dab-ev/DAB12-135EV-TDS-EN.pdf

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português