| Ligne 19 : | Ligne 19 : | ||

{{TutoVideo | {{TutoVideo | ||

|VideoType=Mp4 | |VideoType=Mp4 | ||

| − | |mp4video= | + | |mp4video=For a video tutorial ,check our file. |

}} | }} | ||

{{Materials | {{Materials | ||

Version du 13 décembre 2020 à 20:01

Introduction

e-waste lights: Reusing recycled material to 3D print products

With the current shortage of landfills, and crime during electricity cuts, the team came with a solution to produce 3D printed solar powered street lights using recyclable material. In addition, the solution can be implemented in households and co-operate spaces to produce products that can be 3D printed.Mp4

For a video tutorial ,check our file.

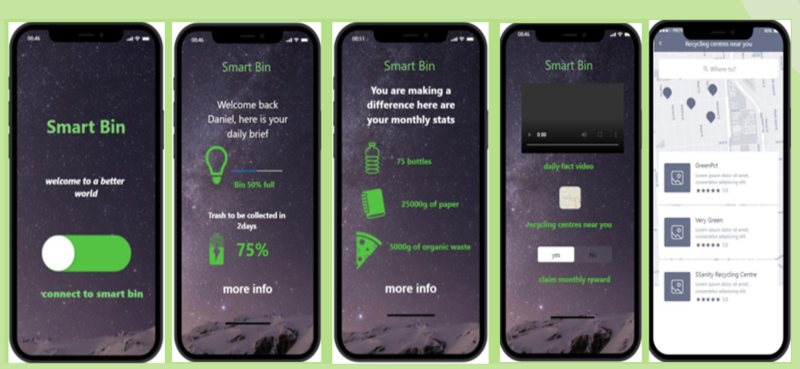

Étape 1 - App creation

The Android app is linked to the smart bin using WIFI or Bluetooth. It collects waste data, contains fun facts to educate people about recycling and waste sorting. To motivate people to keep on sorting their waste, the app also shows you how much money you have accumulated.

Étape 2 - Smart bin

The smart bin, is linked to the app . To create the bin, motors and 4 ultrasonic sensors were used for motion detection, to detect when a user is inserting waste. The board (recyclable wood) was laser cut to divide the waste compartments accordingly.

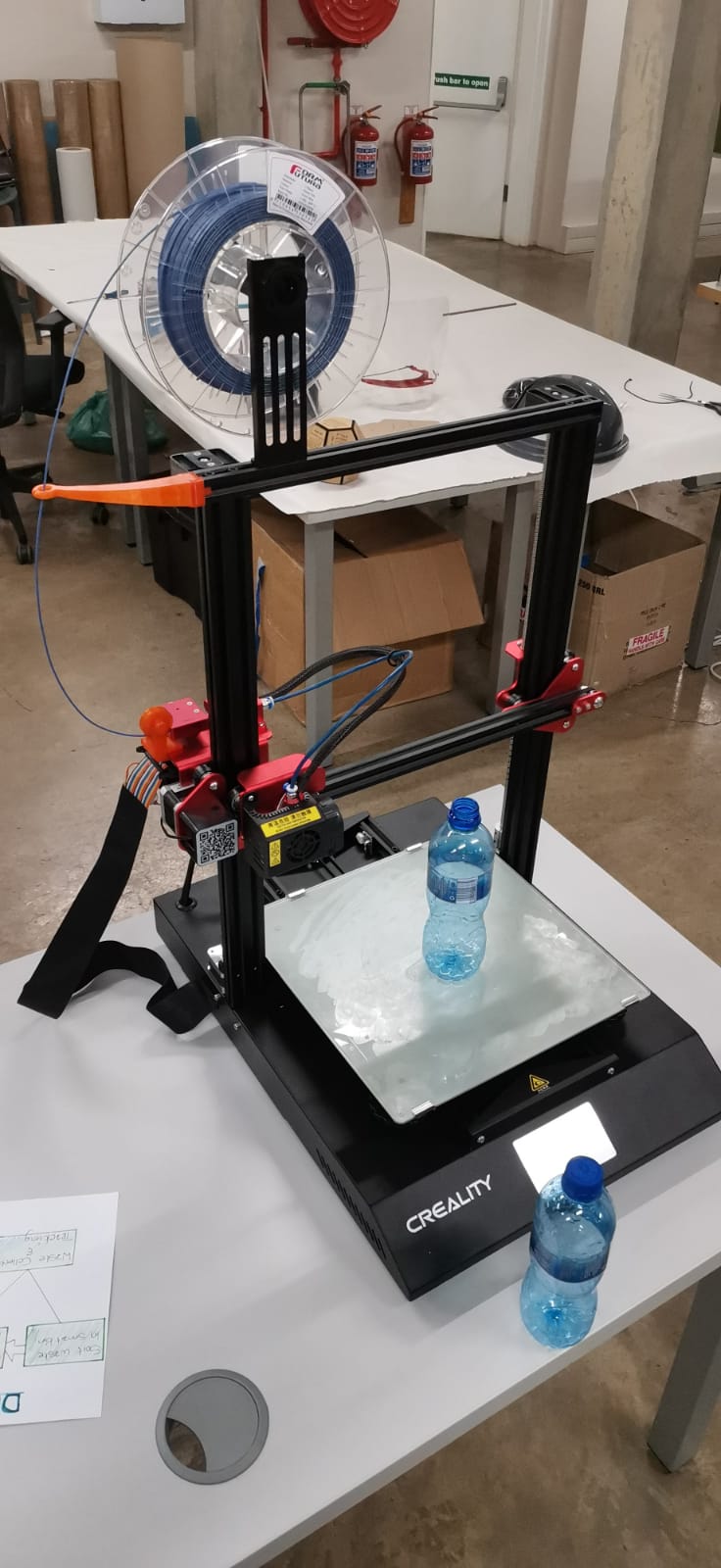

Étape 3 - Production of PETG filament from recycled plastic

Recycle plastics to produce PETG filament for 3D printing.

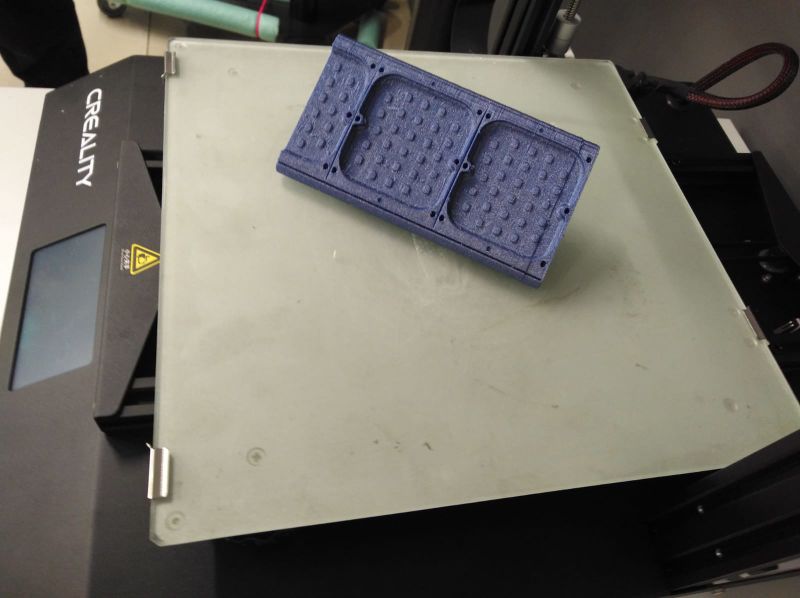

Étape 4 - 3D Print of light

The street light was 3D printed for 10hrs. The PETG obtained from recycled material will be used to 3D print the lights.

Étape 5 - Adding solar panel and other components

To complete assembly of the street light consisted of solar panel, battery, a pole (recyclable wood) and a dark sensor.

Published

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português