(set pageLanguageSource property) |

|||

| Ligne 1 : | Ligne 1 : | ||

{{ {{tntn|Tuto Details}} | {{ {{tntn|Tuto Details}} | ||

| − | | | + | |Main_Picture=Showerloop_09_14.jpg |

| − | | | + | |Licences=Attribution-ShareAlike (CC BY-SA) |

| − | | | + | |Description=<translate>This is the third guide of [[Showerloop:_Water_filtration_and_purification_system|Showerloop]], a real-time filtration, purification & recycling system for shower water.</translate> |

| + | |Area=Energy | ||

|Type=Creation | |Type=Creation | ||

| − | |||

| − | |||

|Difficulty=Easy | |Difficulty=Easy | ||

| + | |Duration=1 | ||

| + | |Duration-type=hour(s) | ||

|Cost=200 | |Cost=200 | ||

|Currency=EUR (€) | |Currency=EUR (€) | ||

| − | | | + | |SourceLanguage=none |

| − | | | + | |Language=en |

| − | | | + | |IsTranslation=0 |

| − | |||

}} | }} | ||

{{ {{tntn|Introduction}} | {{ {{tntn|Introduction}} | ||

|Introduction=<translate>'''This is the third guide of Showerloop, a real-time filtration, purification & recycling system for shower water'''. I accidentally broke the back panel of the shower stall and quickly built a new one with plywood that was routered to fit the frame of the shower stall. This mishap allowed for access to the back which is not very common and so modifications will be required for this step.</translate> | |Introduction=<translate>'''This is the third guide of Showerloop, a real-time filtration, purification & recycling system for shower water'''. I accidentally broke the back panel of the shower stall and quickly built a new one with plywood that was routered to fit the frame of the shower stall. This mishap allowed for access to the back which is not very common and so modifications will be required for this step.</translate> | ||

}} | }} | ||

| − | |||

{{ {{tntn|Materials}} | {{ {{tntn|Materials}} | ||

| − | | | + | |Material=<translate></translate> |

| − | | | + | |Tools=<translate></translate> |

| − | |||

| − | |||

| − | |||

| − | |||

}} | }} | ||

| − | {{Separator}} | + | {{ {{tntn|Separator}}}} |

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

|Step_Title=<translate>Bend copper pipes or just connect the hose</translate> | |Step_Title=<translate>Bend copper pipes or just connect the hose</translate> | ||

| − | |Step_Content=Basics - heat up your copper pipe with a blowtorch. Focus the flame on the areas above and below where you will do the bending so that part doesn’t get hotter and thus weaker than the rest of the steel. | + | |Step_Content=<translate>Basics - heat up your copper pipe with a blowtorch. Focus the flame on the areas above and below where you will do the bending so that part doesn’t get hotter and thus weaker than the rest of the steel. |

Once the copper turns blackish and starts making a cool psychedelic rainbow effect you know the copper is warm enough to begin bending. Turn off the flame and wait a moment. | Once the copper turns blackish and starts making a cool psychedelic rainbow effect you know the copper is warm enough to begin bending. Turn off the flame and wait a moment. | ||

| Ligne 35 : | Ligne 30 : | ||

Once the pipe has cooled a little use the pipe bending tool so make an appropriate bend. This is more craft than technical skill and you just have to observe and see how the metal flexes. | Once the pipe has cooled a little use the pipe bending tool so make an appropriate bend. This is more craft than technical skill and you just have to observe and see how the metal flexes. | ||

| − | {{Dont|Don’t put too much pressure on one spot, this may result in a distorted pipe. You want to keep the diameter of the inner pipe as even as possible. Use a pipe bending tool.}} | + | {{Dont|Don’t put too much pressure on one spot, this may result in a distorted pipe. You want to keep the diameter of the inner pipe as even as possible. Use a pipe bending tool.}}</translate> |

|Step_Picture_00=Showerloop_09_18.jpg | |Step_Picture_00=Showerloop_09_18.jpg | ||

|Step_Picture_01=Showerloop_09_17.jpg | |Step_Picture_01=Showerloop_09_17.jpg | ||

| − | |||

| − | |||

| − | |||

| − | |||

}} | }} | ||

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

|Step_Title=<translate>Hose connexion</translate> | |Step_Title=<translate>Hose connexion</translate> | ||

| − | |Step_Content=Using rubber hose (or PEX) it is much easier than copper but perhaps it won’t look as cool. | + | |Step_Content=<translate>Using rubber hose (or PEX) it is much easier than copper but perhaps it won’t look as cool. |

Transparent tube isn’t too bad but the most common material is PVC (which is kind of nasty). | Transparent tube isn’t too bad but the most common material is PVC (which is kind of nasty). | ||

| Ligne 55 : | Ligne 46 : | ||

{{Idea|For really easy access you can use quick release connectors that allow you to connect and disconnect individual components without twisting the tubes around. These are usually used with garden hoses and are available as plastic or metal pieces.}} | {{Idea|For really easy access you can use quick release connectors that allow you to connect and disconnect individual components without twisting the tubes around. These are usually used with garden hoses and are available as plastic or metal pieces.}} | ||

| − | There's a diagram of how to do this with hose earlier on. | + | There's a diagram of how to do this with hose earlier on.</translate> |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

}} | }} | ||

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

| + | |Step_Title=<translate></translate> | ||

|Step_Content=<translate>Lay out all the filter components onto a surface. Using common sense and a ruler you can centre everything perfectly.</translate> | |Step_Content=<translate>Lay out all the filter components onto a surface. Using common sense and a ruler you can centre everything perfectly.</translate> | ||

|Step_Picture_00=Showerloop_09_01.jpg | |Step_Picture_00=Showerloop_09_01.jpg | ||

|Step_Picture_01=Showerloop_09_05.jpg | |Step_Picture_01=Showerloop_09_05.jpg | ||

| − | |||

| − | |||

| − | |||

| − | |||

}} | }} | ||

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

| Ligne 78 : | Ligne 60 : | ||

|Step_Picture_01=Showerloop_09_07.jpg | |Step_Picture_01=Showerloop_09_07.jpg | ||

|Step_Picture_02=Showerloop_09_06.jpg | |Step_Picture_02=Showerloop_09_06.jpg | ||

| − | |||

| − | |||

| − | |||

}} | }} | ||

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

| Ligne 89 : | Ligne 68 : | ||

|Step_Picture_02=Showerloop_09_11.jpg | |Step_Picture_02=Showerloop_09_11.jpg | ||

|Step_Picture_03=Showerloop_09_12.jpg | |Step_Picture_03=Showerloop_09_12.jpg | ||

| − | |||

| − | |||

}} | }} | ||

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

| + | |Step_Title=<translate></translate> | ||

|Step_Content=<translate>Finally ready to test the filters by attaching a shower hose to the input and output of the flow regulators.</translate> | |Step_Content=<translate>Finally ready to test the filters by attaching a shower hose to the input and output of the flow regulators.</translate> | ||

|Step_Picture_00=Showerloop_09_13.jpg | |Step_Picture_00=Showerloop_09_13.jpg | ||

|Step_Picture_01=Showerloop_09_14.jpg | |Step_Picture_01=Showerloop_09_14.jpg | ||

| − | |||

| − | |||

| − | |||

| − | |||

}} | }} | ||

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

| + | |Step_Title=<translate></translate> | ||

|Step_Content=<translate>The placement of the filters was drawn onto a waterproof material and holes cut where the mount plates go through. | |Step_Content=<translate>The placement of the filters was drawn onto a waterproof material and holes cut where the mount plates go through. | ||

The mount plates can be bent by 90 degrees which would allow for the filters to be hung directly into the wall. To bend acrylic you need a special device that's basically a heated up wire that weakend specifically the bend point. Once it's warm enough you can just bend it by hand and into the shape you want (it's good to have a template that you can push up against). Let it cool and it will harden into shape. It may be prudent to space the holes in such a way that they screw in between tiles as drilling into tiles without cracking them can be tricky. If you have a basic cement wall you are good to go. Alternatively the threaded rod can be extended all the way from the ground to the roof and fastened with tension (pushing up and down) or simple legs or L-bends can be made so that they can be screwed into the roof and or floor. Or just attach the metal rods used to compress the filter directly to the wall.</translate> | The mount plates can be bent by 90 degrees which would allow for the filters to be hung directly into the wall. To bend acrylic you need a special device that's basically a heated up wire that weakend specifically the bend point. Once it's warm enough you can just bend it by hand and into the shape you want (it's good to have a template that you can push up against). Let it cool and it will harden into shape. It may be prudent to space the holes in such a way that they screw in between tiles as drilling into tiles without cracking them can be tricky. If you have a basic cement wall you are good to go. Alternatively the threaded rod can be extended all the way from the ground to the roof and fastened with tension (pushing up and down) or simple legs or L-bends can be made so that they can be screwed into the roof and or floor. Or just attach the metal rods used to compress the filter directly to the wall.</translate> | ||

|Step_Picture_00=Showerloop_09_16.jpg | |Step_Picture_00=Showerloop_09_16.jpg | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

}} | }} | ||

| − | {{ {{tntn|Notes}}|}} | + | {{ {{tntn|Notes}} |

| + | |Notes=<translate></translate> | ||

| + | }} | ||

| + | {{ {{tntn|Tuto Status}} | ||

| + | |Complete=Published | ||

| + | }} | ||

| + | {{Separator}} | ||

Version du 27 juin 2018 à 16:13

Introduction

Matériaux

Outils

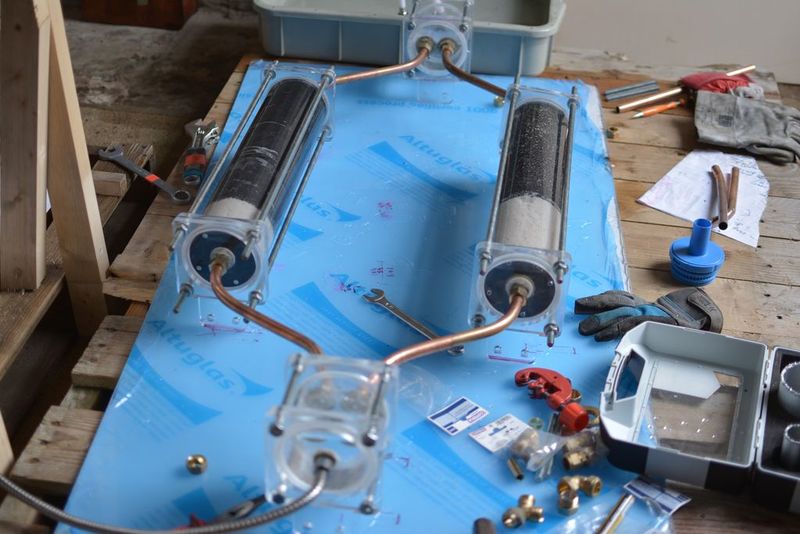

Étape 1 - Bend copper pipes or just connect the hose

Basics - heat up your copper pipe with a blowtorch. Focus the flame on the areas above and below where you will do the bending so that part doesn’t get hotter and thus weaker than the rest of the steel.

Once the copper turns blackish and starts making a cool psychedelic rainbow effect you know the copper is warm enough to begin bending. Turn off the flame and wait a moment.

Once the pipe has cooled a little use the pipe bending tool so make an appropriate bend. This is more craft than technical skill and you just have to observe and see how the metal flexes.

Étape 2 - Hose connexion

Using rubber hose (or PEX) it is much easier than copper but perhaps it won’t look as cool.

Transparent tube isn’t too bad but the most common material is PVC (which is kind of nasty).

The best and perhaps easiest option is to use drinking water hose (16mm?).

The hose connection is simple, use a hose nipple instead of the threaded connector and fasten the hose with a ring clamp. Make sure it’s really right.

There's a diagram of how to do this with hose earlier on.

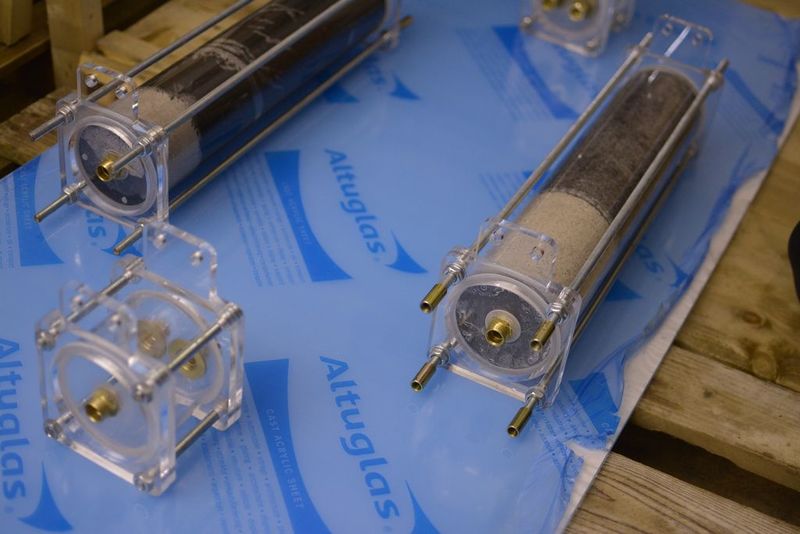

Étape 3 -

Lay out all the filter components onto a surface. Using common sense and a ruler you can centre everything perfectly.

Étape 5 - Cut the pipe

To help cut the pipe you can use a pipe cutting tool but the cheap ones get dull really quickly.

Étape 6 -

Finally ready to test the filters by attaching a shower hose to the input and output of the flow regulators.

Étape 7 -

The placement of the filters was drawn onto a waterproof material and holes cut where the mount plates go through.

The mount plates can be bent by 90 degrees which would allow for the filters to be hung directly into the wall. To bend acrylic you need a special device that's basically a heated up wire that weakend specifically the bend point. Once it's warm enough you can just bend it by hand and into the shape you want (it's good to have a template that you can push up against). Let it cool and it will harden into shape. It may be prudent to space the holes in such a way that they screw in between tiles as drilling into tiles without cracking them can be tricky. If you have a basic cement wall you are good to go. Alternatively the threaded rod can be extended all the way from the ground to the roof and fastened with tension (pushing up and down) or simple legs or L-bends can be made so that they can be screwed into the roof and or floor. Or just attach the metal rods used to compress the filter directly to the wall.

Published

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português